Fire pumps are the heart of a building’s fire protection system. They provide the pressure and flow required to supply sprinklers, hydrants, and hose reel systems when municipal water pressure is insufficient. While much attention is often given to pump selection, certifications, and performance ratings, one of the most critical yet underestimated factors in real-world fire protection effectiveness is installation quality.

Even the highest-quality, fully certified fire pump can fail to deliver its designed performance if it is installed improperly. Poor installation can reduce flow, cause pressure instability, increase mechanical stress, shorten service life, and, in the worst cases, lead to system failure during a fire emergency. For building owners, contractors, fire protection engineers, and facility managers, understanding why fire pump installation quality directly affects performance is essential to ensuring long-term safety and compliance.

This article explores how installation quality impacts fire pump performance, the key technical areas that influence system reliability, common installation mistakes, and best practices to ensure your fire pump system operates as designed when it matters most.

1. Installation Is the Foundation of Fire Pump Performance

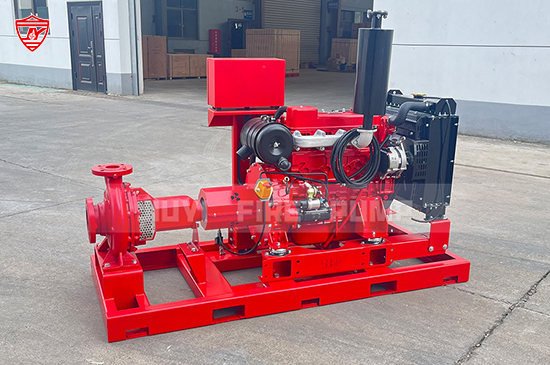

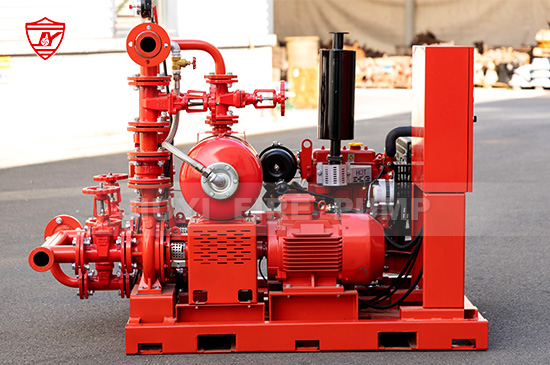

Fire pump performance is not determined solely by the pump itself. Performance is the result of a complete system, including the pump, driver, controller, suction and discharge piping, valves, power supply, foundation, and alignment. Each of these elements must be correctly installed to ensure that the system can deliver the rated flow and pressure under emergency conditions.

A fire pump is designed and tested in controlled factory conditions. In the field, however, performance is influenced by real-world variables such as site layout, pipe routing, power stability, environmental conditions, and installation workmanship. If these factors are not carefully controlled, the pump may experience cavitation, vibration, excessive noise, reduced efficiency, or mechanical failure. Installation quality is therefore not a secondary concern but a primary determinant of system performance.

2. Impact of Suction Piping on Pump Performance

One of the most critical aspects of fire pump installation quality is suction piping design and execution. Improper suction piping is a leading cause of poor fire pump performance in the field.

When suction piping is undersized, poorly routed, or improperly supported, it can create turbulence and pressure losses that reduce the available net positive suction head. This can lead to cavitation, which damages impellers, causes vibration, and reduces flow capacity. Even small deviations from recommended installation practices, such as installing elbows too close to the pump inlet or failing to maintain straight pipe runs, can significantly affect performance.

Air leaks on the suction side are another common issue. Poor flange alignment, inadequate sealing, or improper gasket installation can allow air to enter the system, leading to priming problems, unstable pressure, and reduced pumping efficiency. Over time, these issues can cause premature wear and unpredictable operation during emergency starts.

3. Foundation and Alignment: Mechanical Stability Matters

Fire pumps operate under high mechanical loads, especially during startup and full-load operation. The quality of the pump foundation and alignment between the pump and driver plays a crucial role in maintaining stable performance.

An inadequate foundation can lead to vibration, misalignment, and structural movement during operation. This not only reduces hydraulic performance but also accelerates wear on bearings, couplings, and seals. Over time, even minor misalignment can lead to increased energy consumption, reduced reliability, and higher maintenance costs.

Precision alignment ensures that the motor or diesel engine transfers power efficiently to the pump shaft. Poor alignment increases friction and mechanical stress, which can cause overheating, shaft deflection, and coupling failure. In emergency fire scenarios, these mechanical weaknesses may result in delayed startup or unexpected shutdown, compromising system performance when it is needed most.

4. Electrical and Power Supply Installation Quality

For electric fire pumps, power supply reliability and electrical installation quality are fundamental to performance. Improper cable sizing, inadequate voltage stability, or poor controller installation can prevent the pump from reaching its rated speed and output.

Voltage drop during startup is a common issue in poorly designed electrical installations. If the motor does not receive sufficient voltage, it may struggle to accelerate to full speed, resulting in lower flow and pressure output. Repeated low-voltage starts can also damage motor windings and reduce long-term reliability.

Controller installation quality also matters. Incorrect wiring, improper grounding, or poorly configured control logic can lead to false alarms, nuisance trips, or delayed response during emergency activation. The fire pump system must be able to start automatically and reliably under fire conditions, and this reliability depends heavily on correct electrical installation.

5. Diesel Fire Pump Installation and Fuel System Integrity

For diesel fire pumps, installation quality extends beyond mechanical alignment to include fuel system integrity, ventilation, exhaust routing, and cooling arrangements.

Improper fuel line installation can introduce air into the system, leading to hard starts or stalling under load. Inadequate fuel filtration or poorly secured fuel tanks increase the risk of contamination and leakage. Ventilation and exhaust routing also affect performance, as insufficient airflow can cause overheating and power loss, while poor exhaust design can create back pressure and reduce engine efficiency.

Cooling system installation quality directly impacts the diesel engine’s ability to operate continuously at rated load. If cooling water piping or heat exchanger installation is substandard, the engine may overheat during extended operation, leading to derating or automatic shutdown. In a prolonged fire scenario, this can result in loss of water supply at a critical time.

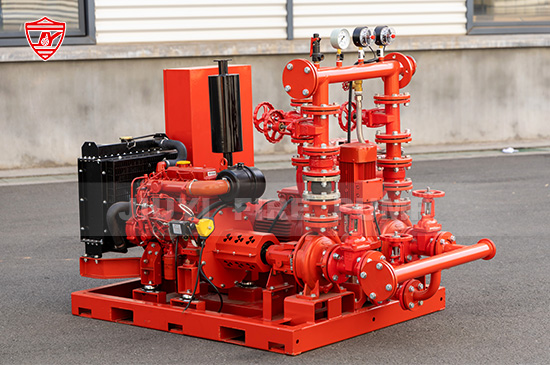

6. System Integration and Hydraulic Balance

Fire pump performance must be evaluated as part of the entire fire protection system. Installation quality affects how well the pump integrates with sprinklers, hydrants, and control valves.

Incorrect valve orientation, poorly installed check valves, or misconfigured pressure relief systems can cause pressure fluctuations, water hammer, and unstable flow. Hydraulic imbalances can result in uneven distribution of water throughout the system, reducing the effectiveness of downstream fire protection devices.

Pressure sensing lines and gauges must be correctly installed to provide accurate feedback to controllers and operators. If these components are improperly positioned or calibrated, the system may not respond correctly to pressure changes, leading to delayed pump activation or improper pressure regulation.

7. Commissioning and Acceptance Testing Reflect Installation Quality

Commissioning and acceptance testing are often the first real validation of installation quality. Performance tests that fall short of design specifications frequently reveal installation-related issues rather than pump manufacturing defects.

Common problems discovered during commissioning include excessive vibration, unstable pressure curves, insufficient flow at rated conditions, and abnormal noise. These symptoms often trace back to issues such as misaligned piping, inadequate foundation stiffness, or incorrect electrical configuration.

High-quality installation reduces the likelihood of costly rework during commissioning and helps ensure that acceptance tests accurately reflect the pump’s true performance capability. Thorough pre-commissioning checks and careful installation supervision can significantly reduce delays and corrective work.

8. Long-Term Reliability and Maintenance Implications

Installation quality has a direct impact on long-term reliability and maintenance requirements. Systems that are poorly installed tend to experience more frequent failures, higher maintenance costs, and shorter component life.

Vibration caused by misalignment or weak foundations accelerates wear on bearings and seals. Poor piping support leads to stress on pump flanges and casing, increasing the risk of leaks and structural damage. Electrical issues can result in repeated motor failures or controller malfunctions.

In contrast, well-installed fire pump systems operate more smoothly, maintain stable performance over time, and require less corrective maintenance. This reliability is especially important in critical facilities such as hospitals, data centers, industrial plants, and high-rise buildings, where fire protection system downtime is unacceptable.

9. Common Installation Mistakes That Reduce Performance

Several recurring installation mistakes are commonly observed in the field and can significantly reduce fire pump performance:

Improper suction piping layout with insufficient straight runs

Undersized suction or discharge piping

Inadequate foundation design or poor grouting

Misalignment between pump and driver

Incorrect electrical cable sizing or controller wiring

Poor ventilation for diesel engine rooms

Improper valve installation or orientation

Insufficient support for heavy piping loads

Each of these mistakes may appear minor during construction but can have serious consequences during operation. Preventing these issues requires adherence to installation standards, careful planning, and quality control during construction.

10. Best Practices for High-Quality Fire Pump Installation

To ensure optimal fire pump performance, several best practices should be followed throughout the installation process:

Early involvement of experienced fire protection engineers during design

Strict adherence to fire pump installation standards and manufacturer guidelines

Detailed review of pump room layout, piping design, and electrical infrastructure

Use of qualified installers with proven experience in fire pump systems

Precision alignment and proper foundation preparation

Thorough inspection and testing before commissioning

Clear documentation of installation procedures and test results

Quality installation is not a one-time task but a process that spans design, construction, inspection, and commissioning. Each stage contributes to the final performance of the fire pump system.

Conclusion

Fire pump installation quality is a decisive factor in determining real-world performance, reliability, and safety of fire protection systems. Even the most advanced and certified fire pump cannot compensate for poor installation practices. From suction piping design and mechanical alignment to electrical integration and commissioning, every detail influences how effectively the pump will perform during an emergency.

For building owners and project stakeholders, investing in high-quality installation is not an optional upgrade but a fundamental requirement for ensuring life safety and asset protection. For fire pump manufacturers, promoting proper installation practices and providing technical guidance helps ensure that products deliver their full performance potential in the field.

Ultimately, fire pump installation quality is the bridge between theoretical performance and real-world fire protection effectiveness. When that bridge is built.