Fire pumps are the heart of a building’s fire protection system, responsible for delivering reliable and adequate water pressure when an emergency occurs. Among the many technical factors that determine pump performance, the priming process is one of the most critical—yet often overlooked—steps in ensuring correct pump operation.

Improper or incomplete priming is one of the most common causes of pump malfunction, especially during the initial startup or after long periods of inactivity. For fire safety professionals, installers, and facility owners, understanding the fire pump priming process is essential to guaranteeing system readiness.

This article provides a detailed, practical explanation of what fire pump priming is, how it works, what types of pumps require priming, the risks of improper priming, and best practices for maintaining primed conditions in a fire protection system.

Priming is the process of removing air from the pump casing and suction line and replacing it with water before the pump starts operating. A fire pump must be fully filled with water to generate the required pressure. If air remains trapped inside, the pump will not function correctly.

A fire pump that runs without being properly primed can experience issues like:

Loss of pump efficiency

Air binding

Overheating

Mechanical damage

Failure to deliver water during a fire emergency

Priming ensures that water is already inside the pump volute and suction piping, enabling the impeller to create the necessary vacuum to draw more water into the pump.

Unlike many industrial pumps, fire pumps often remain idle for long periods. During this time, trapped air, leaks, or maintenance activities can cause the pump to lose its prime.

For a fire protection system, losing prime can be dangerous because:

The pump may fail to start properly during an emergency.

The system may not achieve required pressure, failing NFPA standards.

Dry running can severely damage internal components.

Correct priming is a foundational step that ensures the fire pump is always ready for instant and reliable operation.

Not all fire pumps are the same, and the need for priming varies by design.

Centrifugal fire pumps, including horizontal split-case, end-suction, and multistage pumps, require priming before operation because they are not self-priming.

If the pump casing contains air, the impeller cannot generate sufficient suction, resulting in:

No flow

Cavitation

Internal damage

Vertical turbine fire pumps operate with their bowl assembly submerged in the water source. These pumps are self-priming by design because the impellers are below the water level.

The column pipe remains full of water, so they maintain prime naturally. However, they still require inspection to confirm that water levels remain adequate.

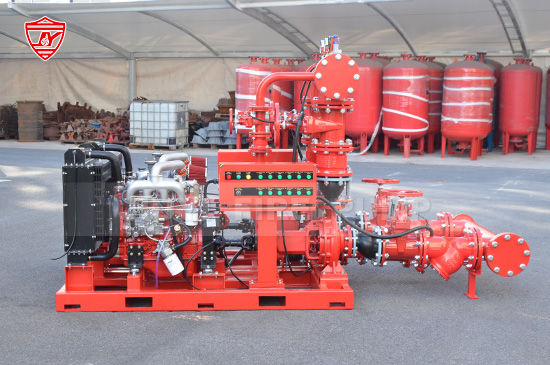

Both diesel and electric fire pumps require the same priming principles. The power source does not change the hydraulic requirement of eliminating air from the pump casing.

Priming involves creating a water-filled environment inside the pump casing and suction line. Below is the typical sequence:

The suction piping must be filled with water from the water tank, underground tank, or municipal supply. Any air trapped inside begins to rise toward the pump casing.

Air pockets inside the casing are released through:

Priming valves

Vent valves

Manual bleeding

Automatic priming systems (in some installations)

Once the air escapes, water fills the entire casing.

A stable water column between the water source and the pump must be maintained. Without it, the pump may lose suction and run dry.

Before the pump is put into service:

Pressure should be stable

No air should escape from vents during operation

Pump performance should meet design pressure and flow

Different installations require different priming solutions. Here are the commonly used methods:

A technician manually opens vent valves to release trapped air until water flows steadily.

This method is common during:

Commissioning

Maintenance

Repairs

Automatic priming devices maintain prime during standby periods. These systems typically include:

Vacuum priming pumps

Air release valves

Float-operated valves

Vacuum tanks

They ensure that even if air enters the system, it is quickly removed.

A foot valve installed at the end of the suction pipe prevents water from flowing backward, maintaining a water-filled suction line.

However, they require regular inspection to prevent failures caused by:

Sticking

Corrosion

Debris buildup

Since the bowl assembly is always submerged, priming occurs naturally through the column pipe. This method is preferred in installations with:

Deep wells

Water reservoirs

Wet pits

Loss of prime can often be detected before failure occurs. Warning signs include:

Pump running but no water discharge

Unusual noise from the pump

Sudden pressure drop

Cavitation or rattling sounds

Excessive vibration

Overheating

During weekly no-flow testing, these signs should never be ignored.

Understanding why priming issues occur can help prevent expensive downtime or system failures.

Air leaks in the suction piping allow air to enter:

Flange gaskets

Elbows

Valve connections

Mechanical seals

Even a small leak can break the water column.

If the tank water level drops below the suction pipe opening, the pump may take in air.

If these valves fail to hold water in the suction pipe, priming is lost.

Long idle periods lead to:

Air buildup

Seal wear

Corrosion

Debris settling

Incorrect piping layouts can trap air pockets, such as:

High points in the suction line

Long horizontal runs

Improperly sized suction pipes

Maintaining a well-primed fire pump is part of maintaining a reliable fire protection system. Here are best practices recommended for professionals.

Follow these principles:

Keep suction piping as straight and short as possible

Avoid sudden diameter changes

Ensure downward slope toward the pump

Minimize elbows and fittings

Properly placed air release valves help remove trapped air quickly.

Low water levels are a major cause of priming failure. Daily checks are recommended.

Tasks include:

Testing check valves

Inspecting seals

Checking for leaks

Cleaning strainers

According to fire protection standards, weekly testing ensures that:

The pump starts correctly

Suction pressure is stable

No air remains trapped

Reliable accessories reduce the chances of losing prime suddenly.

To better understand the importance of priming, consider how priming works in two common installation types.

Here, the pump is usually installed above the water level.

Priming is critical because:

Suction lift is required

Air easily enters the system

A foot valve must hold water in the pipeline

Automatic priming systems are often used to maintain readiness.

The impellers remain submerged.

Advantages include:

Natural self-priming

No air pockets

Stable water column

However, maintaining proper water level is still essential.

Dry running happens when the pump runs without water. This can cause:

Overheating

Mechanical failure

Impeller damage

Seal failure

Proper priming is the primary prevention against dry running. Technicians should ensure the pump is always water-filled before starting any testing or commissioning work.

Priming plays a direct role in code compliance and system reliability:

A properly primed pump can instantly deliver required pressure

Test results are stable and consistent

Cavitation risk is lower

Pump lifespan is extended

Compliance with fire safety standards is easier to maintain

For building owners and fire protection engineers, ensuring correct priming is a long-term investment in system reliability.

Although priming may seem like a small technical detail, it is one of the core factors that determine whether a fire pump will perform when needed most. Air inside a fire pump is a silent threat—it reduces efficiency, causes failure, and can lead to catastrophic consequences during an emergency.

By understanding the fire pump priming process, maintaining proper suction design, and following reliable testing protocols, fire safety professionals can guarantee the pump is always ready to protect lives and property.

A well-primed fire pump is a reliable fire pump.