Fire pump skid design is one of the most important processes in building a reliable fire protection system. For many fire protection projects—commercial buildings, industrial plants, warehouses, oil & gas facilities, or municipal systems—the skid design determines not only how well the fire pump performs, but also how safe, stable, and long-lasting the entire system will be. A professionally engineered fire pump skid ensures smoother installation, reduced vibration, longer equipment life, easier maintenance, and full compliance with industry standards such as NFPA 20 and UL.

As a manufacturer of fire pumps, we understand that engineers, contractors, and end users need clear, practical guidance. This article explains everything you need to know about fire pump skid design, including components, layout considerations, material selection, standards, safety factors, and common mistakes to avoid.

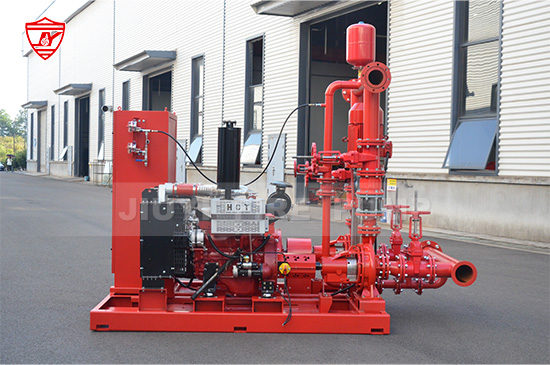

A fire pump skid is a pre-engineered, structurally reinforced base frame that supports one or more fire pumps and their related components. It keeps all equipment aligned, stable, and ready for installation as a packaged unit.

A typical fire pump skid may include:

Main fire pump (electric or diesel)

Diesel engine with controller

Electric motor with controller

Jockey pump and controller

Base frame

Piping connections

Cooling and fuel systems (for diesel units)

Pressure gauges, valves, and accessories

This packaged skid reduces installation time, ensures precise alignment, and keeps equipment protected from excessive vibration or structural stress.

The skid is the foundation of the fire pump system. A poorly designed base will cause:

Misalignment between pump and driver

Excessive vibration

Shaft or bearing damage

Coupling failure

Noisy operation

Early equipment fatigue

More importantly, a critical fire pump may fail during an emergency. Proper skid engineering ensures reliability, safety, and long service life.

The base frame is the structural platform of the skid. It must support the full operating weight of the pump, motor, diesel engine, fuel tank, and piping.

A good base frame design includes:

High-strength steel construction

Rigid reinforcement to minimize deflection

Correct thickness and load distribution

Anchor points for secure installation

Anti-corrosion surface treatment

Pump-to-driver alignment is essential for smooth operation. Skid design must ensure:

Accurate alignment between shaft centers

Adequate spacing for coupling guard installation

Vibration isolation

Access room for service and replacement

Diesel systems require additional skid considerations:

Mounting for fuel tank, cooling system, and exhaust

Extra vibration isolation

Heat dissipation layout

Heavy-duty frame reinforcement

The jockey pump often shares the skid with the main pump or is supplied on its own skid. A good design ensures:

Logical positioning for piping connections

Easy access to the controller

Proper electrical and pressure line routing

Controllers must be installed safely and accessibly. Key design factors include:

Enough clearance for door opening

Compliance with electrical codes

Isolation from vibration

Safe routing for conduit and cables

NFPA 20 sets strict guidelines for:

Pump mounting and alignment

Foundation and base plate rigidity

Vibration control

Clearance space for maintenance

Diesel engine systems and fuel tanks

A compliant skid ensures safety and certification acceptance.

For UL-listed pump assemblies, skid design must meet:

Material and structural requirements

Pump-driver alignment accuracy

Vibration and performance tests

Proper labeling and traceability

A UL fire pump skid provides assurance for global fire protection projects.

Organize the pump, driver, and accessories to:

Ensure efficient workflow

Provide maintenance access

Support clear piping routes

Prevent overheating or interference

Vibration is the top cause of premature pump failure. Good skid design includes:

Thick, reinforced steel frames

Precision leveling

Use of anti-vibration mounts where required

Correct coupling alignment

The skid must allow for:

Easy connection to suction and discharge lines

Proper spacing for valves and check valves

Smooth flow with minimal turbulence

Access for pressure testing

All elements must maintain NFPA 20-required clearance:

Space around controllers

Access paths around engines

Safe exhaust routing for diesel units

Engineers should design for:

Bearing and seal replacement access

Inlet strainer removal

Controller inspection

Pump removal without dismantling the skid

Choose high-strength steel with:

Hot-dip galvanization

Epoxy coating

Anti-rust primer

This ensures long life in harsh environments.

Welding must be:

Uniform

Stress-tested

Non-porous

Compliant with industrial welding codes

Coatings protect the skid from corrosion caused by moisture, chemicals, or outdoor environments.

Features:

Clean and compact design

Minimal vibration

Simple installation

Requires stable power supply

Commonly used in buildings, factories, warehouses, and commercial spaces.

Features:

Independent emergency power

Larger and heavier

Requires fuel system design

More complex cooling and exhaust layout

Ideal for environments with unstable electrical supply or remote locations.

A fully integrated solution with:

Redundant power sources

Reduced installation time

Perfect alignment from the factory

This is popular for large industrial or high-value facilities.

Even the best skid must be installed correctly. Designers should consider:

The foundation must:

Support the entire operating load

Minimize vibration

Provide proper anchor points

High-quality grouting eliminates voids under the skid and prevents vibration.

Although factory-aligned, minor adjustments are needed after placement.

Piping must not place stress on the pump or skid. Use flexible connectors when necessary.

Correct cable routing ensures safety and reliable operation.

A well-designed skid allows easy maintenance operations such as:

Pump alignment checks

Bearing lubrication

Seal inspection and replacement

Controller calibration

Diesel engine fuel and lube checks

Good design reduces downtime and maintenance costs.

This causes vibration, misalignment, and frequent breakdowns.

Without precision alignment, pump and motor wear out rapidly.

This leads to difficult maintenance and unsafe operation.

Non-compliant designs can be rejected by authorities or fail during operation.

Outdoor or humid environments require strong coatings.

When selecting a manufacturer, look for:

Experience in fire pump system integration

NFPA 20-compliant engineering

UL-listed pump options

Quality welding and fabrication

Factory testing before shipment

Ability to customize skids for special projects

Strong after-sales support

A skilled manufacturer ensures the skid performs as designed for many years.

Fire pump skid design is a critical part of building a reliable fire protection system. A well-designed skid provides structural stability, vibration control, precise pump-driver alignment, easy installation, and long-term operational safety. Following NFPA 20 guidelines, choosing the right materials, designing proper layouts, and avoiding common mistakes ensures the fire pump performs flawlessly when needed.