Fire pump systems are a critical component of any fire protection infrastructure. In seismic-prone regions, their reliability becomes even more crucial, as earthquakes can severely compromise fire safety systems at the very moment they are most needed. Protecting fire pump systems from seismic damage is not only a matter of compliance with codes and standards, but also a fundamental responsibility for ensuring life safety, property protection, and business continuity.

This article provides a comprehensive guide on how to protect fire pump systems from seismic damage, covering seismic risks, design considerations, installation best practices, equipment anchorage, piping protection, and long-term maintenance strategies.

Understanding Seismic Risks to Fire Pump Systems

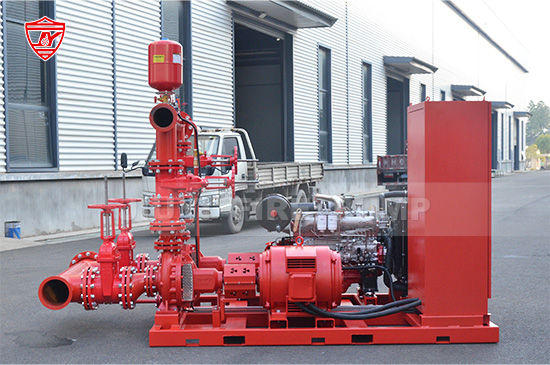

Earthquakes generate dynamic forces that can cause structural movement, vibration, and displacement. Fire pump systems, which consist of heavy mechanical equipment, piping networks, electrical components, and controllers, are particularly vulnerable to these forces.

Common seismic-related failures include:

-

Pump skid movement or overturning due to inadequate anchorage

-

Cracking or rupture of suction and discharge piping

-

Misalignment between pumps and drivers

-

Damage to controllers, fuel tanks, or electrical connections

-

Loss of water supply due to pipe joint failure

Even if the building structure remains intact, a damaged fire pump system can render the entire fire protection system ineffective after an earthquake.

Seismic Design Starts With Risk Assessment

The first step in seismic protection is understanding the seismic risk level of the installation site. Seismic design requirements vary depending on geographic location, soil conditions, building occupancy, and local regulations.

Key factors to evaluate include:

-

Seismic zone classification

-

Site soil type and amplification potential

-

Importance factor of the building

-

Expected ground acceleration levels

Fire pump manufacturers, designers, and installers should work closely with structural engineers to ensure that seismic forces are properly calculated and accounted for during system design.

Fire Pump Anchorage: The Foundation of Seismic Protection

Proper anchorage is the single most important measure for protecting fire pumps from seismic damage. Fire pumps are heavy, rotating machines, and during seismic events, inertia forces can cause them to slide, tip, or detach from their foundations.

Best practices for fire pump anchorage include:

-

Using reinforced concrete foundations designed for seismic loads

-

Installing anchor bolts sized and spaced according to calculated seismic forces

-

Ensuring anchor bolts are embedded to the correct depth

-

Using seismic-rated vibration isolators where permitted

Anchorage design should consider both vertical and horizontal seismic forces and must prevent uplift, sliding, and rotation.

Seismic Bracing for Fire Pump Piping Systems

Fire pump piping is often the most vulnerable part of the system during an earthquake. Long pipe runs, rigid connections, and insufficient supports can lead to joint failure or pipe rupture.

Effective seismic protection for piping systems involves:

-

Installing seismic bracing for both horizontal and vertical piping

-

Using flexible connectors at pump suction and discharge connections

-

Limiting unsupported pipe spans

-

Avoiding rigid connections between equipment and building structures

Flexible couplings help absorb movement and reduce stress transfer from the building to the pump and piping.

Protecting Suction and Discharge Connections

Suction and discharge piping connections are critical stress points during seismic events. Improperly designed connections can transmit excessive forces directly to the pump casing, leading to cracks or misalignment.

Recommended measures include:

-

Installing flexible expansion joints or seismic-rated rubber connectors

-

Ensuring piping loads are independently supported and not carried by the pump

-

Aligning piping accurately to avoid pre-stress during installation

Proper pipe support design ensures that the pump is not subjected to external loads beyond its design limits.

Seismic Considerations for Drivers and Controllers

Fire pump drivers, including electric motors and diesel engines, must also be protected from seismic damage. Controllers, fuel systems, batteries, and electrical conduits are essential for pump operation and must remain functional after an earthquake.

Key protection strategies include:

-

Anchoring controllers and control panels to structural elements

-

Securing diesel fuel tanks with seismic-rated restraints

-

Using flexible electrical conduits to accommodate movement

-

Preventing overhead equipment from falling onto critical components

Electrical continuity and control integrity are just as important as mechanical stability.

Compliance With Seismic Fire Pump Standards

Fire pump systems should be designed and installed in accordance with recognized fire protection and seismic standards. These standards provide minimum requirements for seismic design, anchorage, and bracing to ensure post-earthquake operability.

While specific requirements may vary by jurisdiction, compliance typically covers:

-

Seismic anchorage calculations

-

Bracing requirements for piping and equipment

-

Testing and inspection protocols

-

Documentation and certification

Manufacturers play an important role by supplying fire pump systems that are compatible with seismic design requirements and providing technical data to support engineering calculations.

Installation Quality and Coordination

Even the best seismic design can fail if installation quality is poor. Proper coordination between mechanical, electrical, and structural trades is essential to avoid conflicts and ensure that seismic protection measures are correctly implemented.

Critical installation considerations include:

-

Verifying anchor bolt placement before concrete curing

-

Inspecting bracing installation for correct orientation and spacing

-

Ensuring no field modifications compromise seismic integrity

-

Conducting alignment checks after anchorage installation

On-site supervision and quality control inspections help prevent costly errors that could compromise system performance.

Testing and Inspection After Installation

Seismic protection does not end once installation is complete. Fire pump systems must be inspected and tested to confirm that all seismic measures are correctly installed and functional.

Recommended post-installation actions include:

-

Visual inspection of anchors, braces, and supports

-

Verification of torque on anchor bolts

-

Functional testing of the fire pump system

-

Documentation of seismic protection measures

Periodic inspections should also be conducted as part of routine maintenance, especially in high-risk seismic areas.

Maintenance and Post-Earthquake Readiness

Long-term protection against seismic damage requires ongoing maintenance and preparedness. Over time, vibration, corrosion, or unauthorized modifications can weaken seismic restraints.

Best practices include:

-

Regular inspection of anchors, braces, and flexible connections

-

Prompt repair or replacement of damaged components

-

Keeping fire pump rooms free from unsecured objects

-

Developing post-earthquake inspection procedures

After any seismic event, even minor tremors, a thorough inspection of the fire pump system should be conducted before declaring it fully operational.

The Manufacturer’s Role in Seismic Protection

Fire pump manufacturers play a vital role in seismic protection by designing robust equipment, providing detailed installation guidelines, and supporting engineers and contractors with technical expertise.

A reliable manufacturer should offer:

-

Clear foundation and anchorage recommendations

-

Accurate weight and center-of-gravity data

-

Compatibility with seismic bracing systems

-

Technical support during design and installation

Selecting a manufacturer with experience in seismic applications significantly reduces risk and enhances system reliability.

Conclusion

Protecting fire pump systems from seismic damage is essential for ensuring fire safety when it matters most. Through proper risk assessment, robust anchorage, effective seismic bracing, flexible connections, quality installation, and ongoing maintenance, fire pump systems can remain operational even after major earthquakes.

For building owners, designers, and fire protection professionals, investing in seismic protection is not just about code compliance—it is about safeguarding lives, assets, and critical infrastructure. For manufacturers, delivering fire pump systems designed with seismic resilience in mind is a responsibility that directly contributes to safer communities worldwide.