Fire pump systems are the heart of any active fire protection system. While selecting a UL listed fire pump and ensuring NFPA 20 compliance are essential, the physical layout of the fire pump room is equally critical. A poorly designed pump room can delay inspections, complicate maintenance, increase failure risks, and even lead to non-compliance during authority inspections.

Optimizing fire pump room layout for inspection access is not only a best practice but a long-term investment in system reliability, safety, and operational efficiency. This article provides a practical, manufacturer-oriented guide to designing fire pump rooms that support efficient inspection, testing, and maintenance throughout the system’s lifecycle.

Fire pumps are not “install and forget” equipment. They require regular inspection, weekly or monthly testing, annual performance evaluations, and occasional repairs. If inspectors and technicians cannot safely and easily access critical components, the likelihood of missed defects and system failure increases significantly.

Poor inspection access can result in:

Delayed detection of mechanical or electrical issues

Increased labor time and maintenance costs

Safety hazards for technicians

Non-compliance with fire codes and insurance requirements

From a fire safety perspective, accessibility directly impacts reliability. From a business perspective, it affects lifecycle cost and regulatory approval.

Before discussing layout optimization, it is essential to understand the regulatory framework that governs fire pump rooms.

NFPA 20 provides clear guidance on fire pump room design, emphasizing:

Adequate clearances around pumps, drivers, and controllers

Safe access to all serviceable components

Unobstructed pathways for inspection and removal

Local fire codes, insurance requirements, and authority having jurisdiction expectations may add additional constraints, but NFPA 20 remains the baseline reference worldwide.

Optimizing inspection access starts with interpreting these requirements correctly and applying them practically during design and construction.

Clearance is the foundation of inspection access. Each major component must be accessible without removing unrelated equipment or structural elements.

Recommended layout practices include:

Sufficient space around the pump casing for visual inspection and alignment checks

Adequate clearance behind and beside drivers for lubrication, cooling, and service access

Clear space in front of controllers for safe operation and testing

Crowding equipment to minimize room size may reduce construction cost initially, but it significantly increases inspection difficulty and long-term maintenance expense.

Inspectors should be able to move freely from the entrance to every inspection point without climbing, bending excessively, or passing through hazardous zones.

Effective access planning includes:

Direct walkways from doors to pumps and controllers

No piping, cable trays, or valves blocking access routes

Sufficient headroom for standing inspection

Unobstructed access also improves emergency response if immediate intervention is required during testing or system activation.

Fire pump inspection follows a logical sequence: suction piping, pump casing, coupling, driver, controller, discharge piping, and accessories. The layout should support this natural flow.

Best practices include:

Aligning pump, driver, and controller in a linear or logical arrangement

Positioning gauges, valves, and instruments at visible and reachable heights

Avoiding overlapping inspection zones that force inspectors to backtrack

A well-organized layout reduces inspection time and minimizes the chance of overlooked components.

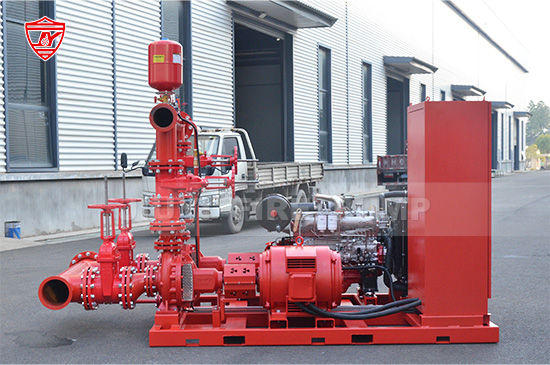

Diesel fire pump rooms demand additional space and planning due to fuel systems, exhaust, and cooling requirements.

Key inspection-related considerations:

Clear access to fuel tanks, filters, and piping

Adequate space around radiators or heat exchangers

Safe clearance near exhaust piping and silencers

Visibility of engine instruments and alarms

Inspection access must allow technicians to check fuel quality, cooling performance, and engine condition without dismantling surrounding equipment.

Electric fire pumps typically require less space than diesel units but still demand careful planning for electrical inspection.

Important layout factors:

Front and side access to controllers and transfer switches

Clear working space for electrical testing and troubleshooting

Separation of electrical components from water leakage risks

Electrical inspectors often require minimum working clearances, which must be incorporated into the initial layout design.

Inspection access is not only about floor space but also vertical positioning.

Effective use of vertical space includes:

Mounting gauges and instruments at eye level

Avoiding high-mounted valves that require ladders

Ensuring overhead piping does not obstruct visibility

Components that require frequent inspection should always be within comfortable reach to reduce risk and improve inspection accuracy.

Even a well-spaced pump room can become inspection-unfriendly if visibility is poor.

Key considerations:

Uniform lighting across all inspection zones

No dark corners behind pumps or controllers

Emergency lighting for power failure scenarios

Environmental factors such as ventilation, temperature, and noise control also affect inspection quality. Inspectors must be able to hear abnormal sounds, observe leaks, and read instruments clearly.

Inspection access should not only support routine checks but also anticipate future maintenance and equipment replacement.

Smart layout planning includes:

Space to remove pump or motor without dismantling walls

Clear paths for lifting or sliding heavy components

Access to coupling alignment points

A pump room designed for future service minimizes downtime and avoids costly structural modifications later.

Despite clear standards, several recurring mistakes appear in fire pump rooms worldwide:

Locating controllers behind pumps or piping

Installing valves too close to walls

Running piping directly in front of inspection panels

Undersizing pump rooms to reduce building footprint

Avoiding these mistakes requires early coordination between designers, manufacturers, and installers.

As a fire pump manufacturer, we consistently see that inspection challenges are rarely caused by the pump itself. They are almost always the result of layout decisions made during early design stages.

An optimized fire pump room layout:

Protects the investment in high-quality fire pumps

Supports compliance with NFPA 20 and local codes

Improves system reliability over decades of operation

Manufacturers can provide valuable input on minimum service clearances, inspection points, and component accessibility during the design phase.

Optimizing fire pump room layout for inspection access is a critical yet often underestimated aspect of fire protection system design. A well-planned layout enhances safety, simplifies compliance, reduces maintenance costs, and ensures the fire pump performs reliably when it is needed most.

By prioritizing clearance, logical arrangement, unobstructed access, and long-term serviceability, project stakeholders can transform the fire pump room from a cramped utility space into a professional, inspection-ready environment that supports the highest standards of fire safety.

Designing for inspection is not an extra cost. It is a safeguard for performance, compliance, and lives.