Industrial plants are high-risk environments where fire safety systems must be carefully designed and robust enough to respond to potential hazards. A critical part of any industrial fire protection system is the fire pump. These pumps ensure adequate water pressure and flow to firefighting systems like sprinklers and hydrants. However, configuring fire pumps for large industrial facilities involves more than simply installing a standard unit. You need to consider the plant's size, hazard classification, water supply, regulatory standards, and backup systems.

This guide provides a comprehensive overview of how to configure fire pumps specifically for large industrial applications, based on NFPA 20 standards and industry best practices.

1. Understand the Industrial Site Requirements

Before selecting and configuring a fire pump, you must analyze the facility’s layout, operations, and fire risk zones. Key aspects to consider include:

-

Total Area to Be Covered: The larger the area, the higher the demand for pressure and flow.

-

Occupancy Hazards: Facilities that store flammable chemicals or operate high-heat processes need specialized protection.

-

Building Height and Vertical Zones: Taller buildings require higher pressure levels to meet the demand at upper levels.

-

Process Sensitivities: Some industrial processes may require rapid fire suppression, needing more robust pump systems.

A detailed fire risk assessment and hydraulic calculation should be conducted to determine system demands.

2. Select the Right Type of Fire Pump

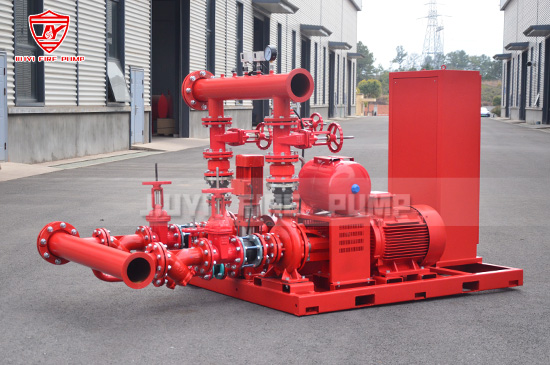

Large industrial plants may require one or more types of fire pumps based on their unique operational needs. The three main types are:

-

Electric Fire Pumps: Efficient and reliable when a stable power source is available. Ideal for indoor settings with robust power infrastructure.

-

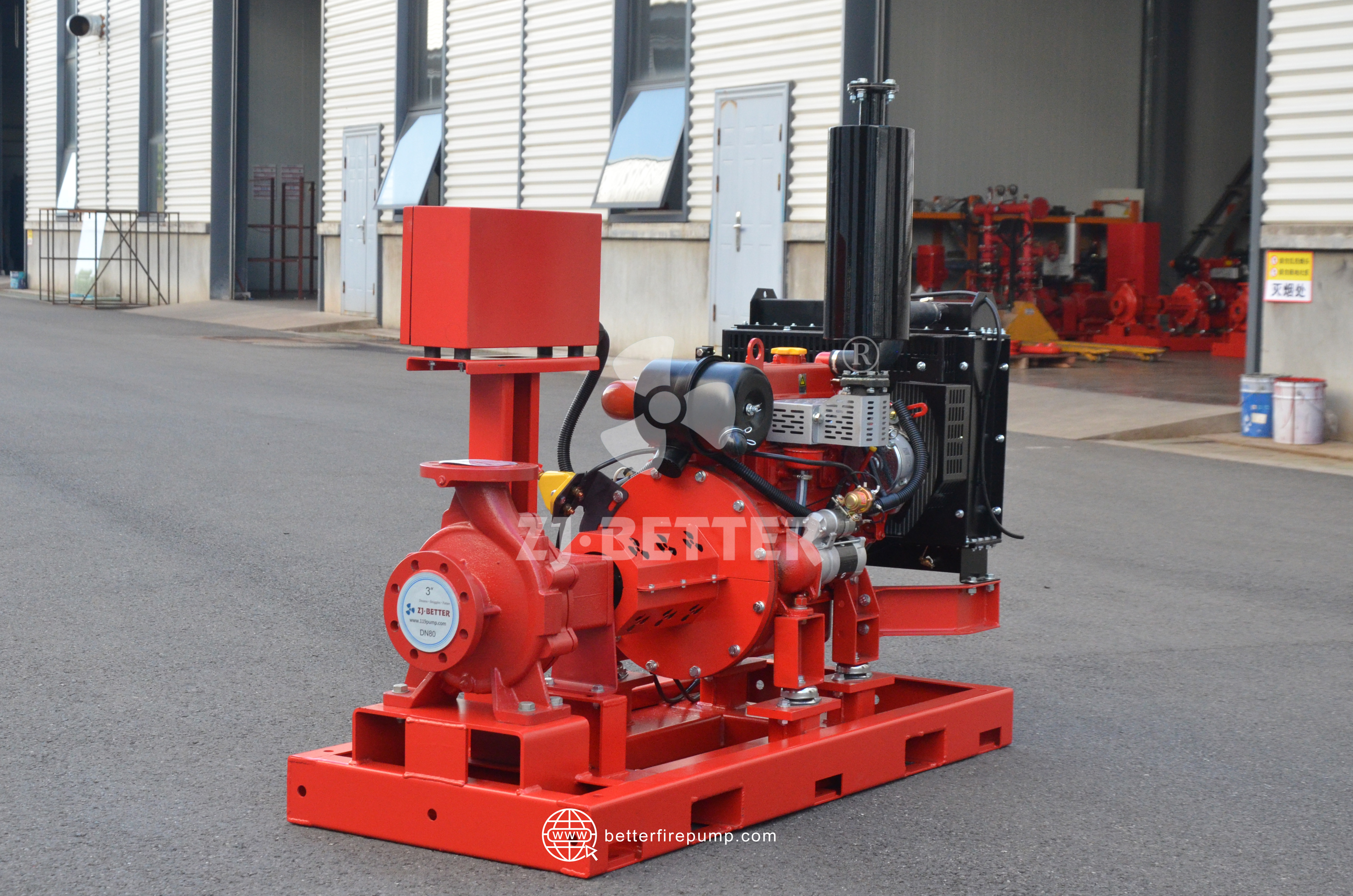

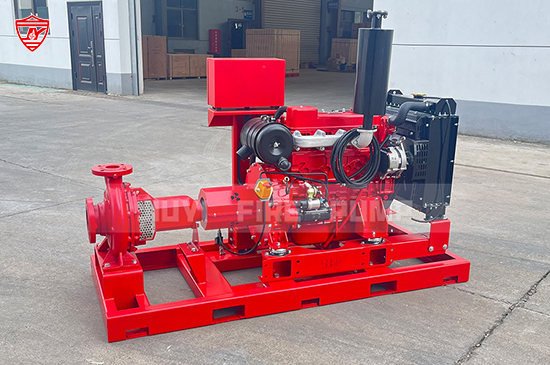

Diesel Engine Fire Pumps: Essential in facilities where power reliability is a concern or as a backup to electric pumps.

-

Vertical Turbine Pumps: Often used where the water source is below the pump, such as in deep wells or tanks.

For large facilities, a diesel backup to the primary electric pump is highly recommended to ensure continued operation during power outages.

3. Ensure NFPA 20 Compliance

NFPA 20 is the leading standard governing fire pump installation. For industrial plants, it provides guidance on:

-

Pump Sizing: The pump must meet or exceed the system demand at the most hydraulically remote point.

-

Redundancy: Backup pumps are recommended to guarantee system availability during maintenance or power failure.

-

Controller Requirements: Controllers must be listed and rated for fire pump service.

-

Testing and Maintenance: Pumps must be tested regularly with results recorded and available for inspections.

Compliance with NFPA 20 not only ensures safety but also simplifies approval from insurance companies and authorities having jurisdiction (AHJ).

4. Choose an Adequate Water Supply

The water supply must support the fire pump’s flow and pressure demand for the required duration, typically 60 to 90 minutes depending on the hazard class. Consider the following sources:

-

Municipal Water Supply: Reliable in urban industrial areas but must be tested for pressure and flow availability.

-

On-Site Water Storage Tanks: Often used as the main or backup supply in rural or high-risk facilities.

-

Wells or Rivers: Require vertical turbine pumps and filtration systems to avoid clogging.

Your configuration must ensure uninterrupted flow, especially during peak firefighting activity.

5. Design Pump Room Layout Thoughtfully

The fire pump room should be:

-

Dedicated and Protected: Separate from high-risk areas and constructed with fire-resistant materials.

-

Well-Ventilated: Particularly important for diesel engine pumps to avoid overheating.

-

Accessible: For maintenance, inspection, and emergency operation.

Also, include space for controllers, jockey pumps, test headers, and relief valves as part of your layout.

6. Integrate with Jockey Pumps and Controllers

Jockey pumps maintain system pressure and prevent false starts of the main pump. In large industrial facilities, multiple jockey pumps may be used in high-demand areas.

Fire pump controllers initiate pump operation and ensure proper sequencing. For industrial applications:

-

Use UL/FM approved controllers

-

Include manual and automatic modes

-

Ensure connectivity with the building management system (BMS) or SCADA

7. Include Pressure Relief Valves and Test Lines

Industrial fire pump systems must incorporate:

-

Pressure Relief Valves (PRVs): To avoid system damage from excess pressure.

-

Test Headers and Flow Meters: For routine performance testing, as required by NFPA 25.

Testing lines must discharge safely and comply with local drainage codes.

8. Plan for Backup Power and Redundancy

Redundancy is essential in industrial environments where downtime could be catastrophic. Best practices include:

-

Diesel backup fire pumps

-

Dual power feeds for electric pumps

-

Automatic transfer switches (ATS) to switch to backup generators

Always ensure that backup systems can handle full fire pump load without delay.

9. Implement Remote Monitoring and Alarm Integration

Large facilities benefit greatly from integration with remote monitoring systems. These systems allow facility managers and safety personnel to:

-

Monitor pump status in real time

-

Receive alarms for system faults or performance issues

-

Automate reports for compliance tracking

Link the fire pump system to the plant’s SCADA or BMS for centralized control and safety assurance.

10. Maintenance Planning and Staff Training

No configuration is complete without a robust maintenance and training plan:

-

Weekly and Monthly Inspections: Check pump performance, power systems, and valves.

-

Annual Flow Tests: Confirm that the system can still deliver required flow and pressure.

-

Training for Staff: Ensure operators understand the pump system and emergency procedures.

Work with your pump manufacturer or service provider to set up a preventive maintenance contract.

Final Thoughts

Configuring fire pumps for large industrial plants is a highly customized process that must address the facility’s layout, hazards, and operational needs. A properly configured system not only saves lives but also protects assets and ensures business continuity. Working closely with qualified fire pump manufacturers and adhering strictly to NFPA 20 standards is essential for success.

At zhejiang jiuyi fire pump, we specialize in designing and manufacturing UL-listed, NFPA 20-compliant fire pump systems for complex industrial applications. Whether you require electric, diesel, or vertical turbine fire pumps, our team can help engineer a turnkey solution tailored to your plant's safety needs.

Contact us today to discuss your project or request a custom configuration proposal. Your safety is our mission.