In any fire protection system, fire pumps serve as the lifeblood of water delivery. But while system components like pipes, sprinklers, and valves often get attention, a critical yet often overlooked element is the start sequence timing of fire pumps.

In this article, we explore why the timing of fire pump activation—especially in systems with multiple pumps or controllers—plays a crucial role in safety, system integrity, and operational reliability. We'll also review best practices for sequencing, common mistakes, and how compliance with standards like NFPA 20 ensures a safe and effective fire protection system.

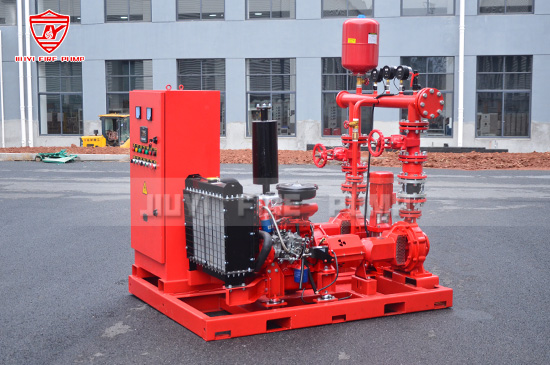

Start sequence timing refers to the programmed delay and order in which different fire pumps (e.g., jockey pump, electric fire pump, diesel fire pump) start during an emergency.

A typical system includes:

Jockey Pump – Maintains system pressure during minor leaks or pressure drops.

Primary Fire Pump – Kicks in when the pressure drop exceeds a threshold.

Secondary or Backup Pump – Activates if the primary fails or additional flow is required.

The start sequence ensures each pump turns on in the correct order, with appropriate time delays, to prevent equipment damage and ensure water delivery.

When a fire emergency is detected, the fire pump system must respond instantly but intelligently. Improper start sequencing can result in:

Simultaneous pump starts causing voltage dips or generator overload.

Water hammer or pressure surges damaging pipelines or fittings.

Pump conflicts where multiple pumps run unnecessarily, reducing efficiency.

False system alarms or tripping of circuit breakers due to power spikes.

Correct start timing prevents these issues and ensures:

Smooth pressure buildup

Controlled electrical load

Reduced risk of mechanical stress

System reliability and longevity

The National Fire Protection Association (NFPA) 20 standard provides detailed requirements for the installation and operation of fire pumps. It specifies that:

Pumps should be automatically controlled and must start upon pressure drop or manual command.

Each pump should have its own controller, programmed with time delays to avoid simultaneous starts.

Diesel and electric pumps should not start at the same time to prevent power supply overload.

UL-listed and FM-approved controllers usually include programmable delays to meet these compliance standards.

In complex facilities such as industrial plants, logistics centers, or high-rise buildings, multiple fire pumps may exist in parallel or redundant configurations. Here’s how the sequence typically works:

The jockey pump starts first upon a slight pressure drop. It maintains pressure without activating the larger fire pumps unnecessarily.

If pressure continues to drop, the electric fire pump starts after a time delay (usually 5–10 seconds). This prevents premature activation due to transient drops.

If the electric pump fails or system pressure remains low, the diesel engine-driven pump starts as a last resort, typically after 10–15 seconds more.

This hierarchy ensures controlled power usage, safety, and orderly operation.

When two or more pumps start simultaneously, particularly large horsepower motors, the electrical system can suffer a major voltage drop or even failure. Facilities using generators as backup power are especially vulnerable.

Proper start sequence timing helps:

Prevent overloading of standby generators

Maintain voltage stability

Avoid nuisance breaker tripping

Reduce risk of fire pump failure during actual emergencies

Consider a warehouse with:

One jockey pump (1.5 HP)

One electric fire pump (75 HP)

One diesel fire pump (100 HP)

If a pressure drop is detected:

The jockey pump starts immediately

After 5 seconds, if pressure is still low, the electric fire pump starts

After an additional 10 seconds, the diesel pump kicks in (only if needed)

This staggered approach prevents simultaneous current draw from the 75 HP and 100 HP pumps, protecting the power infrastructure.

Modern fire pump control panels offer flexibility in timing. Common settings include:

Start delay: How long the controller waits before starting the pump.

Sequential startup: Programming multiple controllers with staggered times.

Manual override: Ability to start pumps manually without delay if needed.

Pressure thresholds: Customizable setpoints to control start sequence triggers.

Ensure each controller is properly configured and regularly tested to verify these delays are functional and effective.

NFPA 25 requires regular testing of fire pump systems. During these tests, engineers should verify:

Each pump starts in the correct order

Time delays are functional

Controllers operate within programmed settings

Power sources (utility or generator) handle load sequencing effectively

Annual flow tests, weekly churn tests, and monthly inspections are key to confirming proper operation.

Failing to stagger start times can result in simultaneous startup, stressing electrical systems.

Fire pump controllers must be properly configured according to system design and local code.

Some technicians disable delay features for “faster response,” but this often creates new risks.

Not accounting for generator startup load when sequencing fire pumps may lead to full system failure during emergencies.

Consult your fire protection engineer when setting or changing timers.

Use UL-listed controllers with programmable delays.

Verify compliance with NFPA 20 and local codes.

Perform full-system startup simulations under real-world power conditions.

Maintain as-built documentation for troubleshooting.

Keep a log of timer settings and changes during maintenance.

In fire protection systems, timing is everything. Proper fire pump start sequence timing ensures your system operates safely, reliably, and in compliance with global standards like NFPA 20.

Whether you're managing a high-rise building, an industrial plant, or a warehouse, sequencing your fire pumps correctly can be the difference between a controlled emergency response and catastrophic failure.

As a manufacturer of fire pumps, we strongly recommend facilities managers, consultants, and engineers prioritize start sequence programming during design, installation, and maintenance.

Need help choosing the right controller or fire pump package with smart sequencing? Contact our team at zhejiang jiuyi fire pump — we offer fully integrated, NFPA 20-compliant fire pump systems built for safety and performance.