Fire pump reliability is the backbone of any fire protection system. When a fire occurs, the fire pump must operate immediately and continuously, regardless of external conditions. Among all potential risks, power failure is one of the most critical threats to fire pump performance. Grid outages caused by fire, natural disasters, or equipment failure can render an electric fire pump useless if no proper backup measures are in place.

For fire safety professionals, ensuring fire pump reliability during power failure is not optional—it is a fundamental requirement of life safety design. This article explores practical, code-aligned strategies to ensure fire pumps remain operational when normal power is unavailable, drawing on engineering best practices and real-world project experience.

Fire pumps are designed to supply water at the required pressure and flow to sprinklers, hydrants, and standpipe systems. During a fire event, electrical infrastructure is often one of the first systems to be compromised. Power cables may be damaged by heat, switchgear rooms may be affected by smoke or water, and utility power may be intentionally shut down by authorities.

If a fire pump cannot start or sustain operation due to power failure, the entire fire protection system is effectively disabled. This risk is why fire codes and standards place such strong emphasis on power reliability, redundancy, and independent energy sources.

Most fire pump systems rely on one of the following power configurations:

Electric motor-driven fire pumps powered by the utility grid

Diesel engine-driven fire pumps with on-site fuel supply

Electric fire pumps supported by emergency generators

Each option has different implications for reliability during power failure. Selecting the right configuration depends on project conditions, regulatory requirements, and acceptable risk levels.

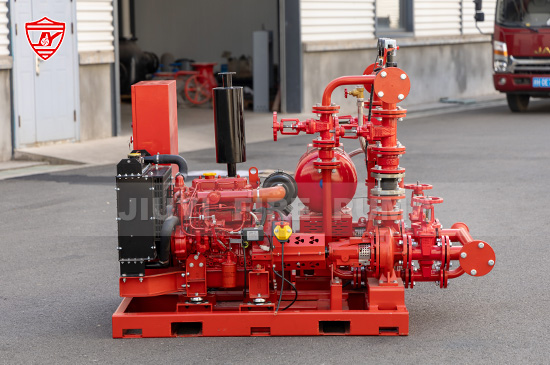

Diesel engine fire pumps are widely regarded as the most reliable option during power failure. Because they do not depend on external electrical power to operate, they offer true independence from the utility grid.

Key reliability advantages of diesel fire pumps include:

Self-contained power source

Automatic start upon pressure drop

Continuous operation as long as fuel is available

Minimal dependency on external infrastructure

However, reliability is only achieved when the diesel system is properly designed and maintained. Fuel storage capacity must meet code requirements, fuel quality must be preserved, and batteries must be fully charged and tested regularly.

For facilities in regions with unstable power supply or high-risk fire environments, diesel fire pumps are often the preferred solution.

Electric fire pumps can remain reliable during power failure when paired with a properly sized and dedicated emergency generator. This configuration is common in high-rise buildings, hospitals, data centers, and industrial facilities.

To ensure reliability, the generator system must meet several critical conditions:

The generator must be sized to handle fire pump starting current

Fire pump loads must be prioritized over non-essential loads

Automatic transfer switches must operate without delay

Generator fuel supply must support extended operation

A common failure point is underestimating the inrush current required to start an electric fire pump motor. If the generator cannot handle this demand, the fire pump may fail to start during an emergency.

One of the most effective strategies for ensuring fire pump reliability during power failure is the use of dual power supplies. This approach provides two independent sources of power, ensuring continuity if one source fails.

Typical dual power configurations include:

Utility power plus emergency generator

Two independent utility feeds

Electric fire pump combined with diesel fire pump backup

Dual power supply design significantly reduces single-point failure risks and is strongly recommended for critical facilities. While initial investment may be higher, the long-term safety and compliance benefits often outweigh the cost.

While jockey pumps do not replace fire pumps during power failure, they play an important role in overall system reliability. By maintaining system pressure under normal conditions, jockey pumps reduce unnecessary fire pump starts, minimizing wear and extending equipment life.

In power failure scenarios, a well-designed jockey pump system ensures that the fire pump starts only when truly needed, preserving available backup power and fuel.

A fire pump is only as reliable as its control system. During power failure, fire pump controllers must automatically detect abnormal conditions and initiate operation without human intervention.

Reliable fire pump control panels should include:

Automatic start logic based on pressure drop

Manual override capability

Clear alarm and status indicators

Compatibility with emergency power sources

Poorly designed or improperly tested control panels are a common cause of fire pump failure during emergencies. Routine testing under simulated power failure conditions is essential.

Reliability during power failure is not only about the power source itself. Supporting components must also be designed with redundancy and durability in mind.

Critical components to consider include:

Batteries for diesel engines

Fuel transfer and filtration systems

Cooling systems

Starting circuits and wiring

Failure of any of these components can prevent a fire pump from operating, even if sufficient power is technically available.

Even the best-designed fire pump system can fail if it is not properly maintained. Regular inspection, testing, and maintenance are essential to ensure reliability during power failure.

Effective maintenance practices include:

Weekly or monthly fire pump test runs

Routine diesel engine start tests

Generator load testing with fire pump startup

Battery voltage and charger inspections

Fuel quality monitoring

Testing should simulate real emergency conditions as closely as possible, including power loss scenarios. This is the only way to identify hidden weaknesses before an actual fire occurs.

Environmental factors can significantly affect fire pump reliability during power failure. Flooding, extreme temperatures, and poor ventilation can all compromise system performance.

Best practices include:

Installing fire pumps above flood-prone areas

Ensuring adequate ventilation for diesel engines

Protecting control panels from heat and moisture

Maintaining clear access for inspection and emergency service

Fire pump rooms should be treated as critical infrastructure spaces, not as secondary utility areas.

Fire pump reliability during power failure is heavily regulated by international and local fire codes. These standards define minimum requirements for power supply, redundancy, and performance.

Compliance is not just about passing inspections—it is about ensuring real-world performance when lives are at stake. Manufacturers, designers, and installers must work together to ensure that fire pump systems meet both the letter and intent of applicable standards.

Finally, system reliability starts with the manufacturer. A high-quality fire pump designed for emergency conditions provides a strong foundation for long-term performance.

When selecting a fire pump manufacturer, consider:

Proven experience in fire protection applications

Robust testing and quality control processes

Compatibility with emergency power systems

Technical support for system design and commissioning

A reliable manufacturer understands that fire pumps are not ordinary pumps—they are life safety equipment that must perform flawlessly under the most demanding conditions.

Ensuring fire pump reliability during power failure requires a combination of proper equipment selection, intelligent system design, redundancy, and disciplined maintenance. Whether through diesel engine fire pumps, emergency generators, or dual power configurations, the goal is the same: uninterrupted fire protection when it matters most.

By addressing power failure risks proactively and designing systems with real emergency conditions in mind, fire safety professionals can ensure that fire pumps perform their critical role—protecting lives, property, and infrastructure—without compromise.