Energy consumption in fire protection systems is often overlooked, as safety and reliability are always prioritized. However, with the rising focus on sustainability, reducing the energy usage of fire pump operations has become a key concern for building owners, facility managers, and fire protection engineers. Optimizing a fire pump system for energy efficiency lowers operational costs and contributes to long-term sustainability goals — without compromising performance or compliance with NFPA 20 and other standards.

In this article, we explore practical strategies to reduce energy consumption in fire pump operations — from system design and selection to maintenance and modern control technology.

Fire pumps are designed to operate at full capacity when required, typically during emergencies. However, the system components — such as jockey pumps, controllers, and standby systems — may consume energy even when the fire pump itself is idle.

The total energy consumption of a fire pump system depends on:

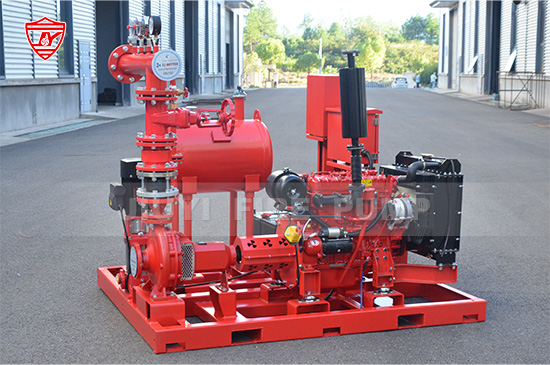

Pump type and efficiency (centrifugal, vertical turbine, end suction, etc.)

Driver type (electric motor or diesel engine)

Control methods (direct-on-line, soft starter, variable speed drive)

Maintenance condition (wear, misalignment, leakage, etc.)

System design (pressure settings, piping layout, and suction conditions)

Understanding where the energy goes is the first step to finding opportunities for improvement.

Energy savings start with selecting the right fire pump. Oversized or inefficient pumps lead to unnecessary power consumption and increased wear over time.

Key selection considerations include:

Accurate system demand analysis: Calculate the actual required flow and pressure based on building layout, sprinkler system design, and local code requirements.

Avoid oversizing: Oversized pumps operate far from their best efficiency point (BEP), resulting in wasted energy and premature wear.

Choose high-efficiency models: Modern UL/FM certified fire pumps are designed for higher hydraulic efficiency and improved performance under variable load conditions.

Match driver and pump performance: Ensure that the electric motor or diesel engine operates within its optimal efficiency range for the expected load.

By ensuring the right pump size and performance characteristics, operators can achieve immediate energy savings and reduce lifecycle costs.

Incorrect or excessive pressure settings cause pumps to work harder than necessary. Regularly reviewing and adjusting pressure settings helps maintain efficiency and protect system components.

Practical optimization steps:

Set realistic pressure margins: Avoid setting discharge pressure too high; it increases motor load and energy use.

Use jockey pumps efficiently: The jockey pump maintains system pressure between pump operations. Selecting the right size and controlling its start/stop frequency reduces unnecessary power use.

Install variable speed drives (VSDs) for special applications: Although NFPA 20 restricts the use of VFDs in some fire pump systems, variable speed control can be effective in non-critical auxiliary systems or test loops, reducing energy during partial load operation.

Modern control systems can also monitor pressure fluctuations and adjust operation automatically to minimize idle energy waste.

A poorly maintained fire pump consumes more energy and delivers less output. Routine maintenance ensures the pump runs close to its best efficiency point and avoids unnecessary energy loss.

Maintenance actions that improve energy performance include:

Inspect and clean impellers regularly: Dirt and corrosion reduce efficiency by creating flow resistance.

Check alignment and coupling: Misalignment increases vibration and friction, wasting energy.

Monitor bearings and lubrication: Properly lubricated bearings reduce mechanical losses.

Replace worn seals: Leakage not only wastes water but also affects hydraulic performance.

Test pump performance annually: Measure flow, head, and current draw to verify the system operates efficiently and complies with NFPA 25 standards.

A consistent maintenance schedule reduces both energy consumption and the risk of failure during an emergency.

The motor driving the fire pump represents a major source of power consumption. Using high-efficiency or premium-efficiency motors can yield significant savings over the pump’s service life.

Considerations for motor selection:

Select IE3 or IE4 efficiency class motors for new installations.

Inspect insulation and windings regularly to prevent overheating and power loss.

Upgrade to smart controllers that optimize startup and monitor motor health.

For diesel-driven systems, ensuring the engine operates within its optimal speed range and is properly maintained helps reduce fuel consumption and emissions.

Hydraulic losses in the piping system directly increase the pump’s workload. Reducing friction loss and turbulence in the system leads to better energy performance.

Ways to improve piping efficiency:

Use smooth and adequately sized pipes: Smaller or rough pipes increase resistance and energy demand.

Avoid unnecessary bends and fittings: Each bend or valve creates head loss that the pump must overcome.

Maintain proper suction conditions: Ensure adequate water supply and prevent cavitation, which damages the impeller and reduces efficiency.

Install flow meters and pressure gauges: Monitoring allows for timely detection of abnormal flow resistance.

A well-designed piping network not only saves energy but also enhances system reliability and fire protection performance.

Energy optimization is not a one-time task; it requires ongoing monitoring and performance evaluation.

Recommended actions:

Record power and flow data during each test: Compare readings to baseline performance to identify inefficiencies.

Analyze trends over time: Gradual increases in energy use often indicate wear or improper adjustment.

Engage certified technicians for periodic audits: Professional testing ensures compliance with standards and provides actionable improvement recommendations.

Performance audits also help facilities justify energy-saving investments with clear data.

The use of intelligent control panels and monitoring systems allows facility managers to track performance in real time and make data-driven decisions.

Benefits of smart fire pump management systems include:

Energy monitoring: Measure actual power draw and identify inefficiencies.

Predictive maintenance: Early alerts for vibration, pressure, or flow anomalies reduce downtime.

Remote diagnostics: Technicians can adjust parameters or schedule maintenance without on-site inspection.

System optimization: Advanced software can analyze patterns to optimize start/stop cycles and minimize idle time.

Such automation can lead to measurable energy savings, especially in large commercial or industrial facilities with multiple pumps.

When purchasing or upgrading fire pumps, it is essential to evaluate total cost of ownership, not just the purchase price.

An energy-efficient pump may have a slightly higher initial cost but typically saves far more in reduced power bills and maintenance expenses over its lifespan. Using life cycle cost analysis (LCC) helps justify investment in high-efficiency equipment and modern control systems.

Finally, the human factor plays a significant role in energy efficiency. Training operators and maintenance staff to recognize and act on energy-saving opportunities ensures that system improvements are sustained over time.

Actions to promote awareness:

Conduct periodic workshops on energy-efficient fire pump operation.

Encourage reporting of abnormal system behavior or energy spikes.

Integrate energy performance indicators into facility management goals.

When energy efficiency becomes part of the company’s operational culture, savings become consistent and measurable.

Reducing energy consumption in fire pump operations requires a holistic approach — starting with efficient design, proper pump selection, optimized control settings, and regular maintenance. Implementing smart monitoring systems, using high-efficiency motors, and improving piping layouts further contribute to sustainable performance.

By focusing on both energy efficiency and system reliability, facility owners can achieve lower operational costs while maintaining full compliance with fire protection standards. For manufacturers and operators alike, the future of fire safety lies not only in reliability but also in responsible energy management.