Fire safety isn’t optional—it’s a critical component of any building’s protection strategy. For manufacturers, engineers, building managers, and safety professionals, fire pumps serve as essential life-saving equipment. But having a fire pump installed is only part of the solution. Regular, mandatory fire pump flow tests are vital to ensure these pumps perform when they’re needed most—during an emergency. This article explores why fire pump flow tests are required by code and regulation, how they safeguard human lives and property, and best practices to support your safety program.

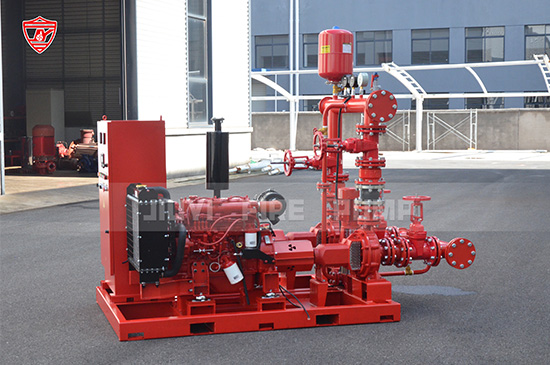

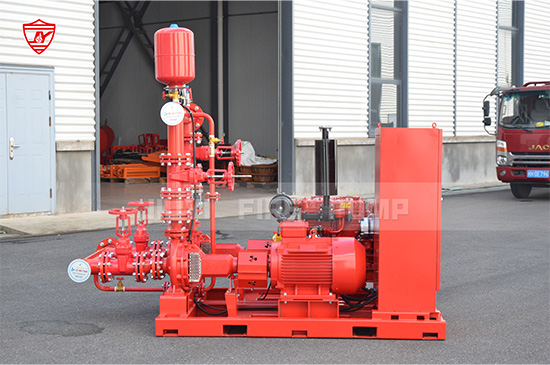

Fire pumps are mechanical systems subject to wear, corrosion, seal degradation, driver malfunctions, and shifting hydraulic conditions. Even if a pump is tested at installation, these factors can silently degrade performance over time. A flow test—where the pump is run at design conditions to verify it can deliver the required flow and pressure—confirms the system will perform as specified when it matters most.

A pump that cannot deliver its rated flow/pressure may result in insufficient water to suppress a fire, leading to uncontrolled fire spread, property damage, and loss of life. Flow testing verifies head, flow, and capacity under real operational scenarios and ensures the pump meets its design curve.

Fire codes and standards such as NFPA 25 (Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems) mandate periodic flow testing of fire pumps. These codes require acceptance testing upon installation and regular re–testing (e.g., annually for flow or weekly/monthly for operational checks, depending on system type).

Without documented flow test results, a facility may fall out of compliance, potentially invalidating insurance, raising liability concerns, and exposing building occupants to undue risk. Governments, insurers, and regulators rely on these test records as proof that fire protection systems remain functional.

Regular flow testing helps detect progressive issues—pump aging, wear, cavitation, broken impellers, motor degradation, suction or discharge problems, or control circuit malfunctions. Many issues that could compromise pump output remain undetected until a real fire occurs. Flow tests proactively identify and allow remediation of such failures before catastrophic consequences.

The most important goal of fire protection is saving lives. Flow testing verifies that fire pumps deliver adequate water under pressure to fire sprinklers, hydrants, standpipes, or other suppression systems. When systems fail, response time is dramatically impacted, smoke spreads, evacuation is delayed, and firefighting strategies are compromised.

Additionally, fire-related downtime, damage, and occupant displacement can threaten business continuity and reputation. Flow test verification minimizes these risks and supports resilient operations.

Insurers often require proof of regular testing and maintenance of fire protection systems. Up-to-date flow test reports reassure insurers and risk managers that systems are properly maintained, helping reduce insurance premiums or prevent policy denial. In absence of such documentation, insurers may question risk exposure in the event of a fire claim.

On commissioning, flow testing confirms that the as-installed system—pump, piping, controllers, valves—matches design assumptions. It validates that installation errors (improper pipe sizing, incorrect valve settings, air pockets, misaligned coupling, voltage irregularities) don’t compromise must-deliver performance. This “proof of performance” baseline is invaluable for future diagnostics and maintenance.

Authorities Having Jurisdiction—fire marshals, municipal code officials—require documented flow test results to issue occupancy permits or system approvals. Flow testing demonstrates that critical fire protection infrastructure is inspected, tested, and maintained as per code, ensuring regulatory acceptance.

Flow tests offer measurable performance data over time. By tracking flow, pressure, and power draw across test intervals, facility managers can trend degradation, schedule maintenance, budget refurbishments, and plan pump replacements proactively. This data-driven strategy extends equipment lifecycle and prevents unexpected failure.

For building owners, facility engineers, and end-users, documented flow tests provide transparency and confidence. Knowing that their fire protection system has proven performance builds trust in safety infrastructure. As a manufacturer, you differentiate your pumps by emphasizing reliability, support for testing, and safety leadership.

Every installed fire pump represents a potential lifeline in a fire event. But without periodic, mandatory flow testing, that lifeline may fail when most needed. Flow testing ensures reliable performance, compliance with codes, early detection of emerging issues, insurance and regulatory acceptance, and a solid foundation for preventive maintenance.

As a leading fire pump manufacturer, you play a pivotal role—not only by supplying equipment, but by empowering your clients with testing protocols, documentation tools, and training to make these mandatory tests efficient, accurate, and effective. Prioritize flow testing and position your organization as the partner that keeps communities safe, systems compliant, and reputations secure.