When it comes to protecting lives and property, a fire pump is one of the most vital components of a building's fire protection system. But owning a fire pump isn’t enough—you must ensure it operates reliably at all times. That’s where a fire pump system audit comes in.

In this article, we’ll break down what a fire pump system audit is, why it’s necessary, what’s involved, and how it benefits facility managers, safety professionals, and building owners.

A fire pump system audit is a comprehensive inspection and performance evaluation of your fire pump and associated systems to ensure they comply with relevant codes (such as NFPA 20 and NFPA 25), perform reliably, and are ready in the event of a fire emergency.

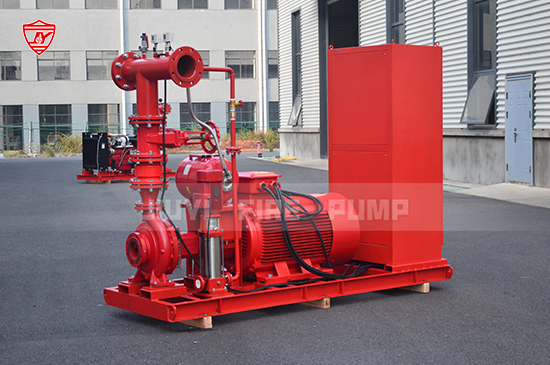

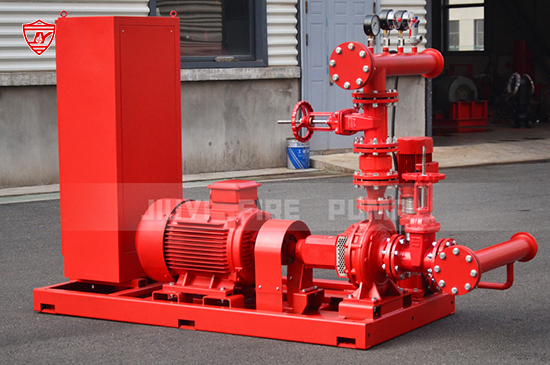

It is typically conducted by certified fire protection specialists or manufacturers like Better Technology Group, who bring the expertise and equipment to assess whether your pump system is working as designed—or if it poses a hidden risk.

Even the most well-designed fire pump systems can degrade over time. Mechanical parts wear out, maintenance may be overlooked, or installation errors might have gone unnoticed. An audit:

Reveals hidden faults that routine inspections may miss

Improves reliability by identifying components at risk of failure

Ensures code compliance, especially with NFPA 25 and local regulations

Reduces insurance liabilities by documenting preventive action

Extends equipment lifespan through early detection of wear and inefficiency

Improves system performance, which is critical during emergencies

In many cases, audits also reveal opportunities to improve energy efficiency and reduce long-term operational costs.

Fire pump audits are essential in a wide range of settings, including:

Commercial buildings (malls, offices, warehouses)

Industrial plants and factories

Hospitals and healthcare facilities

High-rise residential complexes

Airports and transport hubs

Oil & gas, mining, and hazardous industries

Government and military installations

Any property where fire protection is mission-critical should undergo regular audits.

A professional fire pump system audit generally includes both visual inspections and performance-based testing. Here’s a breakdown of key components:

Assessing wear on impellers, casings, and seals

Verifying alignment of the motor or diesel engine

Checking for unusual vibration, noise, or overheating

Confirming correct shaft rotation direction

Inspection of control panels and circuitry

Ensuring compliance with NFPA 20 and UL/FM requirements

Verifying power supply reliability and emergency backup systems

Adequate ventilation and drainage

Room temperature monitoring (important for diesel engines)

Access and clearance for maintenance or emergency response

Conducting a flow test at 100%, 150%, and churn

Comparing actual results against manufacturer specifications

Identifying abnormal pressure drops or system leaks

Checking jockey pump operation for pressure maintenance

Inspecting system valves, gauges, and piping for integrity

Reviewing past maintenance and inspection logs

Identifying lapses or overdue services

Recommending a compliance schedule if gaps are found

According to NFPA 25 (Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems), routine inspections and testing should be conducted monthly, quarterly, or annually depending on the component.

However, a comprehensive fire pump system audit should be scheduled:

Annually for high-risk or mission-critical facilities

Every 2–3 years for standard commercial properties

After major changes such as building renovation, pump replacement, or pipework modification

Following a fire incident or system failure

Some typical issues found during audits include:

Misalignment between pump and driver

Pressure relief valve not properly set or missing

Corrosion inside piping or pump casing

Outdated or non-compliant controllers

Insufficient flow due to pipe obstruction or undersized components

Leaking seals or worn gaskets

Incomplete or incorrect maintenance records

Uncovering and correcting these issues can drastically improve fire safety readiness.

Audits should be performed by qualified professionals with experience in fire protection systems. This can include:

Licensed fire protection contractors

Certified fire pump manufacturers

Third-party testing laboratories

Internal facility maintenance teams (if properly trained)

We offer fire pump system audits tailored to your building type, industry requirements, and local compliance codes. Our team ensures full documentation and provides actionable reports for maintenance or upgrade planning.

While many facilities rely on general contractors or third-party inspectors, working directly with a fire pump manufacturer brings key advantages:

In-depth product knowledge—we understand the specific performance characteristics of every model

Access to proprietary testing equipment—more precise diagnostics

Factory-trained professionals—guaranteed technical expertise

Fast parts replacement and upgrade support

One-stop service—from audit to maintenance to repair

At the conclusion of your audit, you should receive:

A detailed inspection report

Performance test results

A list of non-compliant or high-risk issues

Clear recommendations for corrective actions

An updated maintenance schedule

Cost estimates for necessary repairs or upgrades

Many manufacturers, including us, also offer follow-up services like system retrofitting, controller upgrades, spare parts delivery, or on-site maintenance packages.

A fire pump system audit is not just a compliance task—it’s a proactive fire protection strategy. It helps you uncover risks before they turn into failures, ensuring that your facility is always ready for an emergency.

Whether you’re operating a manufacturing plant, managing a commercial complex, or responsible for public safety infrastructure, regular audits give you the confidence that your fire protection system will perform when it’s needed most.