Fire pump systems are critical life-safety assets designed to perform reliably under the most demanding conditions. However, in many regions around the world—especially deserts, coastal areas, construction zones, and industrial environments—sand and dust pose a serious and often underestimated threat to fire pump performance and longevity.

Fine particles can infiltrate pump components, accelerate wear, obstruct cooling and ventilation, contaminate fuel and lubrication systems, and ultimately lead to pump failure at the worst possible moment. For manufacturers, installers, and end users alike, protecting fire pump systems from sand and dust is not optional—it is essential for ensuring operational readiness, compliance, and long-term value.

This article provides a comprehensive, practical guide on how to protect fire pump systems from sand and dust through proper design, equipment selection, installation practices, and ongoing maintenance.

Sand and dust affect fire pump systems in both visible and hidden ways. While surface contamination may seem harmless, the real damage often occurs internally over time.

Fine dust particles can enter bearings, seals, couplings, and control panels, causing abrasion, overheating, and electrical faults. Sand can accumulate in suction lines, strainers, and cooling passages, restricting flow and reducing pump efficiency. Diesel fire pumps are particularly vulnerable, as airborne dust can contaminate air intake systems, fuel filters, and engine oil, leading to premature engine wear or failure.

In regions with frequent sandstorms, dry climates, or heavy construction activity, these risks are amplified. Without proper protection, even a high-quality fire pump system can suffer reduced service life and increased failure risk.

To protect a fire pump system effectively, it is important to understand where sand and dust are most likely to cause damage.

Dust intrusion accelerates bearing wear, increases friction, and raises operating temperatures. Over time, this can lead to misalignment, vibration, and mechanical failure.

Fine particles can score seal faces and packing surfaces, leading to leakage, reduced efficiency, and unplanned maintenance.

Electric motors and diesel engines rely on airflow for cooling. Dust accumulation can block ventilation paths and cause overheating.

Dust inside control panels can cause insulation breakdown, short circuits, sensor malfunction, and unreliable starting.

Sand entering the water source can settle in suction piping, foot valves, or strainers, restricting flow and increasing pump load.

One of the most effective ways to protect fire pump systems from sand and dust is thoughtful pump room design.

Fire pump rooms should be fully enclosed and properly sealed to prevent airborne dust intrusion. Gaps around doors, cable entries, ventilation openings, and pipe penetrations must be sealed using appropriate materials.

Maintaining slight positive pressure inside the pump room helps prevent dust from being drawn in from outside. This is especially important in dusty or desert environments.

Ventilation is necessary, but openings should be designed with filters, louvers, or labyrinth paths that reduce dust entry while allowing adequate airflow.

Installing fire pump systems above ground level reduces exposure to sand accumulation, especially in flood-prone or wind-driven sand areas.

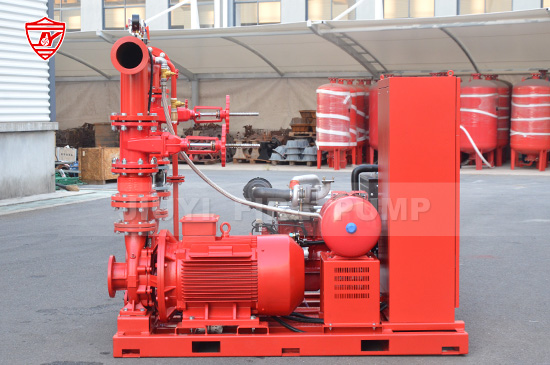

Not all fire pump systems are equally suited for harsh environments. Material selection and system configuration play a major role in dust resistance.

Fire pumps with heavy-duty casings and wear-resistant internal components are better equipped to handle abrasive particles.

Using sealed or shielded bearings minimizes dust ingress and extends bearing life.

Mechanical seals designed for contaminated environments provide better resistance to fine particles compared to basic packing solutions.

Totally enclosed electric motors and well-sealed diesel engines provide superior protection against airborne contaminants.

Diesel fire pump systems are especially sensitive to dust and sand due to their reliance on clean air for combustion.

High-efficiency, multi-stage air filters significantly reduce the amount of dust entering the engine. In extremely dusty regions, pre-cleaners or cyclone filters are strongly recommended.

Air filters must be inspected more frequently in dusty environments. A clogged filter reduces engine performance and increases fuel consumption.

Air intakes should be positioned away from ground level, prevailing wind directions, and areas where dust concentration is highest.

Sand entering the water supply can be just as damaging as airborne dust.

Properly sized suction strainers prevent sand and debris from entering the pump. These strainers must be accessible for regular cleaning.

Where water sources contain high sand content, sedimentation basins or tanks allow particles to settle before reaching the pump.

Correct pipe sizing, smooth flow paths, and minimal turbulence reduce the likelihood of sand accumulation in the suction line.

Fire pump controllers are the brain of the system, and their protection is critical.

Controllers should be housed in dust-tight enclosures designed for industrial environments.

If internal cooling fans are used, filters must be installed and maintained to prevent dust from entering sensitive components.

Scheduled cleaning of control panels helps prevent dust buildup that can lead to overheating or electrical faults.

Even the best-designed system requires disciplined maintenance to remain reliable.

In dusty environments, inspection intervals should be shorter than standard recommendations.

Dust contamination in lubricants accelerates wear. Lubrication systems must be kept clean, and oil analysis can help detect contamination early.

Regular cleaning of pump surfaces, motors, engines, and control panels prevents dust accumulation from migrating into internal components.

Dust-related wear often manifests as increased vibration, noise, or reduced performance. Early detection allows corrective action before failure occurs.

Fire pump systems must not only function reliably but also comply with applicable standards and manufacturer recommendations.

Environmental conditions should be considered during system design and documented during installation. Following manufacturer guidelines for installation, ventilation, filtration, and maintenance ensures that warranty coverage and system certification remain valid.

Investing in proper protection measures offers measurable long-term benefits.

Protected fire pump systems experience fewer breakdowns, lower maintenance costs, and longer service life. Most importantly, they deliver reliable performance when needed most—during an emergency.

For facility owners and operators, this means reduced risk, improved compliance, and greater confidence in their fire protection infrastructure. For contractors and consultants, it means fewer callbacks and stronger project outcomes.

Sand and dust are silent threats that can compromise even the most advanced fire pump systems if left unaddressed. Through thoughtful pump room design, careful equipment selection, effective filtration, and disciplined maintenance, these risks can be significantly reduced.

As a fire pump manufacturer, understanding and addressing environmental challenges is part of delivering true value—not just equipment, but long-term reliability and safety. Protecting fire pump systems from sand and dust is not just good engineering practice; it is a responsibility to the people and assets those systems are designed to protect.