Fire pump installation is one of the most critical stages in any fire protection project. Even minor mistakes during installation can lead to system failure, inspection rejection, project delays, or costly rework. In recent years, fire pump package sets have become the preferred solution for reducing installation errors and improving overall system reliability.

For contractors, consultants, and building owners, understanding why fire pump package sets significantly lower installation risks is essential. This article explains the technical, practical, and operational reasons behind their growing adoption in fire safety projects worldwide.

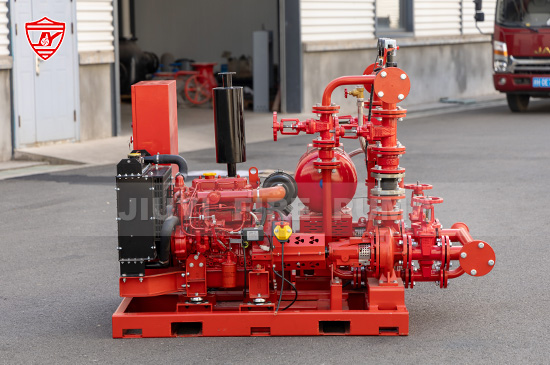

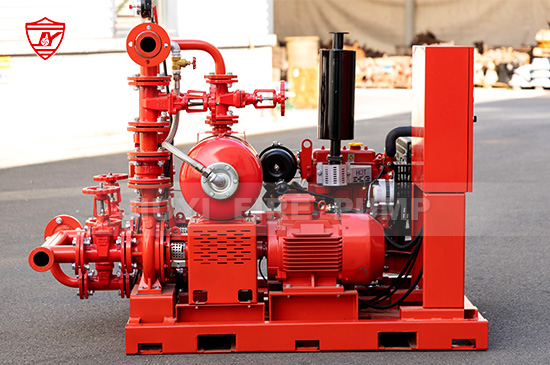

A fire pump package set is a factory-assembled fire pump system that includes the fire pump, driver (electric motor or diesel engine), controller, baseplate, piping, valves, instruments, and accessories, all integrated into a single tested unit.

Unlike traditional site-built systems where components are sourced separately and assembled on-site, packaged fire pump systems are engineered, assembled, and tested under controlled factory conditions. This approach eliminates many variables that commonly lead to installation errors in the field.

Fire pump installation errors occur more frequently than many professionals expect. These errors often stem from coordination issues, inconsistent workmanship, misinterpretation of standards, or poor-quality component matching.

Common installation problems include:

Incorrect pump and driver alignment

Improper suction or discharge piping configuration

Incorrect controller wiring

Valve orientation errors

Inadequate foundation or baseplate leveling

Missing or incorrect accessories

Non-compliance with NFPA 20 or local codes

Each of these mistakes can result in failed acceptance tests, delayed project handover, or system unreliability during emergencies.

Fire pump package sets directly address these challenges.

One of the biggest causes of installation errors is component mismatch. When pumps, motors, controllers, and valves are sourced from different suppliers, compatibility issues often arise.

With a fire pump package set:

All components are engineered as a complete system

Pump performance matches the driver output

Controllers are correctly sized and programmed

Accessories are selected based on system requirements

Factory engineering ensures that every component works together as intended, eliminating errors caused by incorrect selection or sizing.

On-site assembly introduces risk. Field conditions vary, skilled labor availability differs, and installation schedules are often compressed. These factors increase the likelihood of errors.

Fire pump package sets significantly reduce on-site work by delivering a pre-assembled system. This minimizes:

Mechanical assembly errors

Improper torque or fastening

Alignment mistakes

Incorrect component placement

Because most assembly work is completed in a controlled environment, quality consistency is much higher than site-built installations.

Misalignment between the pump and driver is one of the most common and dangerous installation errors. Even slight misalignment can cause:

Excessive vibration

Bearing damage

Seal failure

Reduced pump lifespan

In a packaged fire pump system, alignment is completed and verified at the factory using precision tools. The system is shipped as a single aligned unit, preventing misalignment caused by on-site assembly or improper handling.

Suction and discharge piping errors are frequent causes of fire pump failure during commissioning. Common issues include:

Incorrect pipe diameter

Improper reducer orientation

Insufficient straight pipe lengths

Poorly supported piping

Fire pump package sets include factory-installed piping designed according to NFPA 20 requirements. This ensures:

Correct pipe sizing

Proper valve placement

Correct orientation of fittings

Reduced field welding or modification

By minimizing field piping connections, the risk of installation errors is dramatically reduced.

Fire pump rooms often differ from project to project, leading to confusion during installation. Packaged systems use standardized layouts that installers can easily recognize and follow.

A consistent layout means:

Faster installation

Fewer interpretation errors

Clear identification of components

Simplified inspection process

Installers spend less time guessing and more time executing proven designs.

One of the most valuable advantages of fire pump package sets is factory testing. Each system undergoes performance and functional testing before shipment.

Factory testing helps detect:

Wiring errors

Control logic issues

Mechanical defects

Pressure and flow inconsistencies

Identifying and correcting issues at the factory prevents costly troubleshooting on-site, where repairs are more difficult and time-consuming.

Fire pump systems must comply with strict standards such as NFPA 20, UL, or FM requirements. Site-built systems often fail inspections due to overlooked details or incorrect installations.

Fire pump package sets are designed specifically to meet these standards. Compliance is built into the system rather than dependent on field interpretation.

This results in:

Higher inspection pass rates

Faster approval from authorities

Reduced risk of rework

Greater confidence for consultants and owners

Skilled fire pump installers are not always available, especially in remote or fast-paced projects. Less experienced labor increases the risk of mistakes.

Packaged fire pump systems simplify installation to the point where:

Fewer specialized skills are required

Installation instructions are clearer

Critical adjustments are already completed

This reduces human error and improves consistency across projects.

The longer an installation takes, the more opportunities there are for mistakes. Fire pump package sets significantly reduce installation time by:

Eliminating extensive field assembly

Reducing coordination between trades

Simplifying commissioning

Faster installation means fewer chances for miscommunication, missed steps, or rushed work near project deadlines.

Commissioning is where installation errors are often exposed. Packaged fire pump systems streamline this process because:

System configuration is already validated

Control settings are pre-verified

Performance characteristics are known

This reduces last-minute corrections and increases confidence during final acceptance tests.

Fire pump reliability during an emergency depends heavily on correct installation. Errors that seem minor during construction can cause catastrophic failure during a fire event.

By reducing installation errors, fire pump package sets contribute to:

Reliable system performance

Lower maintenance issues

Longer service life

Improved safety outcomes

For building owners and operators, this reliability is invaluable.

Not all fire pump package sets are equal. Experienced manufacturers understand the importance of system integration, testing, and compliance. A well-designed package reflects years of engineering knowledge and field experience.

Choosing a reputable fire pump package manufacturer ensures:

Accurate system design

Consistent quality control

Reliable technical support

Confidence throughout the project lifecycle

Fire pump package sets reduce installation errors by eliminating design mismatches, minimizing on-site assembly, ensuring factory alignment, integrating compliant piping, and validating performance through testing. They transform fire pump installation from a complex, error-prone process into a streamlined, reliable operation.

As fire protection standards become more demanding and project timelines tighter, packaged fire pump systems are no longer just a convenience. They are a strategic solution for improving safety, reducing risk, and delivering dependable fire protection systems.

For professionals in the fire safety field, understanding and adopting fire pump package sets is a critical step toward error-free installation and long-term system reliability.