When designing or installing a fire pump system, one of the most critical considerations is how water reaches the pump. The performance and reliability of a fire pump depend heavily on the type of suction arrangement used—suction lift or positive suction. While both terms describe how water enters the pump, their differences have major implications for efficiency, compliance with NFPA20 standards, and long-term system reliability.

This article explains suction lift and positive suction in detail, highlights their differences, and explores best practices for each type of fire pump installation.

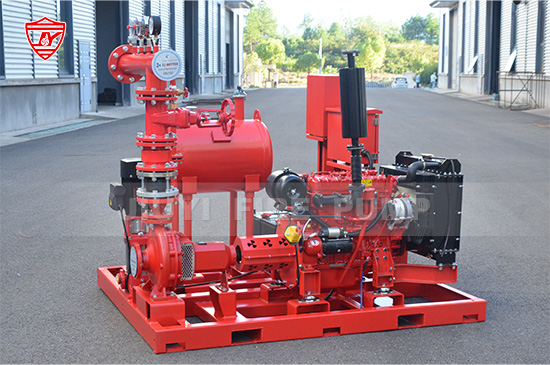

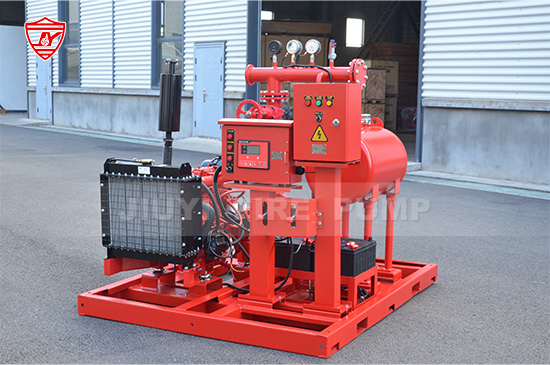

In fire protection systems, centrifugal fire pumps are the most commonly used. For a centrifugal pump to operate effectively, it must be supplied with water at the suction side. The way water is delivered depends on the source (such as a water storage tank, reservoir, or municipal line) and the pump’s positioning relative to that source.

Two key configurations are:

Suction Lift – The water source is below the pump.

Positive Suction – The water source is above or at the same level as the pump.

These arrangements may sound simple, but their technical differences greatly influence system performance.

Suction lift occurs when a fire pump is installed above the water level of its supply source. In this case, the pump must create a vacuum to draw water upward into the impeller.

Pump location: Above the static water level.

Startup: The pump must be primed before operation to remove air and allow water to flow.

Typical sources: Underground tanks, ponds, rivers, or wells.

Pressure condition: The suction side operates under negative pressure relative to the atmosphere.

Priming issues: If air leaks into the suction line, the pump may fail to prime.

Limited height: Physics limits suction lift to about 7–8 meters (23–26 feet) at sea level.

Risk of cavitation: Negative pressure increases the chance of vapor bubbles forming, leading to performance issues or damage.

Maintenance needs: Requires regular checks of suction lines, foot valves, and priming devices.

Remote or rural installations with no pressurized water supply.

Sites where water must be drawn from a below-grade reservoir or open source.

Certain mobile or temporary fire pump applications.

Positive suction occurs when the water source is located above or at the same level as the fire pump. In this setup, water naturally flows into the pump due to gravity or system pressure, eliminating the need for vacuum creation.

Pump location: At or below the static water level.

Startup: Self-filling; no priming required.

Typical sources: Ground-level or elevated tanks, pressurized municipal supplies.

Pressure condition: The suction side operates under positive pressure.

Reliable operation: No need for priming; water is always available at the pump inlet.

Reduced cavitation risk: Positive pressure at suction reduces the chance of vapor bubbles forming.

Better compliance with NFPA20: Positive suction is often preferred for permanent fire protection systems.

Simpler maintenance: Fewer components like priming devices or foot valves are needed.

Most fixed fire pump installations, especially those requiring UL or NFPA20 compliance.

Facilities with dedicated fire water storage tanks.

Urban or industrial sites with pressurized municipal connections.

| Factor | Suction Lift | Positive Suction |

|---|---|---|

| Water Source Level | Below the pump | At or above the pump |

| Pressure Condition | Negative pressure at suction | Positive pressure at suction |

| Startup Requirement | Requires priming | Self-filling, no priming |

| Reliability | Risk of priming failure, cavitation | Highly reliable |

| Maintenance | Frequent checks on suction lines, foot valves | Minimal compared to suction lift |

| NFPA20 Compliance | Limited use; must meet strict priming standards | Preferred arrangement |

| Applications | Remote sites, underground tanks, open sources | Most permanent fire protection systems |

NFPA20, the Standard for the Installation of Stationary Pumps for Fire Protection, sets strict requirements on suction conditions:

Positive suction is strongly recommended wherever possible to ensure reliability.

Suction lift arrangements are only acceptable when specifically engineered and proven capable of maintaining required flows without loss of prime.

The suction piping must be designed to avoid air pockets, sharp bends, or restrictions that can cause turbulence.

Adequate Net Positive Suction Head (NPSH) must be ensured to prevent cavitation.

Compliance is not only about system performance but also about securing UL/FM approvals where required.

Lower efficiency due to energy wasted in creating vacuum.

Greater vulnerability to air leaks and vapor lock.

Reduced long-term reliability.

Stable and efficient water flow.

Consistent operation even during emergencies.

Extended pump life due to reduced cavitation risk.

Consider two fire pump installations:

Scenario 1: Suction Lift

A rural manufacturing plant uses a below-grade reservoir. The fire pump must be installed above ground. Engineers design a priming system and foot valve to maintain prime. Regular maintenance is critical to prevent air leaks.

Scenario 2: Positive Suction

An urban warehouse installs a fire pump connected to a dedicated ground-level storage tank. Gravity ensures continuous water availability. The system operates smoothly with less maintenance and higher compliance confidence.

The second scenario clearly offers superior reliability, aligning with NFPA20 recommendations.

When deciding between suction lift and positive suction:

Evaluate the water source location – If water can be stored at or above pump level, positive suction should be the default choice.

Check regulatory compliance – NFPA20 favors positive suction; using suction lift requires careful engineering justification.

Consider system reliability – In life-safety systems like fire protection, reducing risk is always a priority.

Account for long-term maintenance – Positive suction minimizes operational issues compared to suction lift.

The difference between suction lift and positive suction in fire pumps lies in the relationship between pump and water source levels. Suction lift requires the pump to draw water upward against gravity, while positive suction allows water to flow naturally into the pump.

For most fire protection applications, positive suction is the recommended and more reliable choice, aligning with NFPA20 requirements and ensuring consistent pump performance. Suction lift may be used in specific cases, but it introduces challenges in priming, efficiency, and maintenance.

As a fire pump manufacturer, we emphasize the importance of selecting the correct suction arrangement during system design. A well-planned installation not only ensures compliance but also guarantees dependable fire protection when it matters most.