Fire pumps are the backbone of reliable fire protection systems, designed to deliver water at the necessary pressure and flow during an emergency. But simply installing a fire pump is not enough—its operation must follow the correct sequence to ensure that the system works exactly as intended when lives and property are on the line.

Understanding the proper fire pump start-up sequence is essential for facility managers, fire safety engineers, contractors, and anyone responsible for fire protection systems. In this article, we will walk through the correct sequence of operation for jockey pumps, electric fire pumps, and diesel engine fire pumps. We will also highlight why following the right order is critical for performance, safety, and compliance with standards such as NFPA 20.

The fire pump system is designed with multiple components that work in harmony. The sequence of operation ensures that:

Water pressure remains stable under normal and emergency conditions.

The correct pump engages at the right time, preventing system failure.

Overloading or premature wear of pumps is avoided.

Compliance with fire codes and NFPA 20 is achieved.

If pumps start in the wrong order—or if one pump fails to start—the entire system could be compromised during a fire emergency. That’s why the sequence is carefully engineered to maintain reliability.

Before looking at the exact sequence, let’s quickly review the purpose of each pump in a standard fire pump system:

Jockey Pump (Pressure Maintenance Pump):

The jockey pump is the smallest pump in the system. Its job is to maintain system pressure during small leaks or pressure drops, so the main fire pumps don’t cycle unnecessarily.

Electric Fire Pump:

This is often the primary pump. It starts automatically when the system detects a significant pressure drop beyond the jockey pump’s capability.

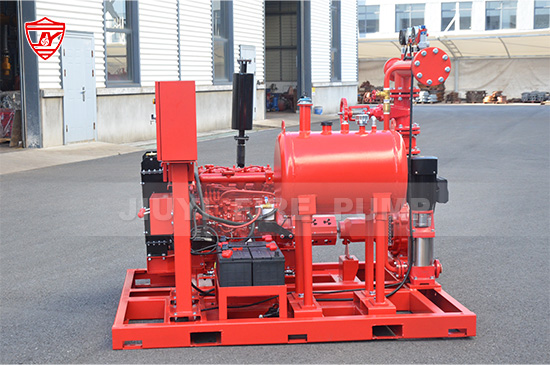

Diesel Engine Fire Pump (if included):

The diesel fire pump serves as the backup to the electric fire pump or as the primary pump in areas where reliable electricity supply is a concern. It provides redundancy and ensures compliance with many fire safety codes.

The sequence of pump start-up is carefully structured to minimize wear and tear while ensuring uninterrupted fire protection. Below is the standard order:

When there is a minor pressure drop (such as from a small leak or pipe expansion/contraction), the jockey pump automatically starts.

It quickly restores the system pressure to the set level.

If the jockey pump cannot restore pressure, the next pump in sequence is triggered.

Key Point: The jockey pump prevents unnecessary cycling of the larger fire pumps.

If the pressure continues to drop beyond the jockey pump’s capacity (such as during sprinkler activation in a fire), the electric fire pump automatically starts.

This pump is designed to deliver large volumes of water at high pressure to the fire protection system.

Once started, the electric pump runs until it is manually shut down—this is required by NFPA 20 to ensure it does not stop prematurely during a fire.

Key Point: The electric fire pump is typically the primary driver in systems where electricity is reliable.

If the electric fire pump fails to start—or in systems where redundancy is required—the diesel fire pump engages.

Diesel pumps are critical in areas prone to power outages or where additional backup is mandated.

Like the electric pump, the diesel fire pump must run until manually shut down.

Key Point: The diesel fire pump provides critical redundancy, ensuring that water supply is never interrupted during an emergency.

When a fire pump starts, supervisory signals are sent to the fire alarm control panel or monitoring system.

These alarms notify personnel that the fire pump is running.

Additional alarms are triggered if there is pump failure, low fuel levels (diesel), or other faults.

Key Point: Monitoring ensures that building operators and fire responders are immediately aware of pump activity or issues.

Let’s consider a real-world example:

A small pressure drop occurs due to minor leakage in the system. The jockey pump starts and restores pressure.

Later, a sprinkler head activates because of a fire. The pressure drop is too large for the jockey pump to handle, so the electric fire pump engages.

If the electric fire pump fails to start, the diesel fire pump immediately kicks in, ensuring water supply is uninterrupted.

Throughout this process, alarms notify operators about which pump is running.

This layered approach guarantees that the system can handle any emergency without interruption.

The NFPA 20 Standard for the Installation of Stationary Fire Pumps for Fire Protection provides the key guidelines for fire pump sequence and operation:

Manual Shutdown Only: Once started, both electric and diesel fire pumps must continue to run until manually stopped.

Sequential Operation: Jockey → Electric → Diesel.

Monitoring and Alarms: Supervisory signals are mandatory for proper system operation and compliance.

Automatic and Reliable: Pumps must start automatically upon detecting pressure drops.

Following NFPA 20 is not only a legal requirement in many jurisdictions but also the best way to guarantee safety and system reliability.

Even though the sequence may seem straightforward, mistakes in design, installation, or maintenance can cause problems:

Improper jockey pump sizing can lead to frequent cycling of the main pumps.

Incorrect pressure settings may cause pumps to start too early or fail to engage at all.

Failure to test start-up sequences regularly can result in undetected faults.

Skipping redundancy (diesel backup) leaves the system vulnerable in case of power failure.

Solution: Always follow manufacturer recommendations, NFPA 20 guidelines, and conduct regular fire pump testing.

Routine Testing: Perform weekly or monthly fire pump tests to confirm proper sequence.

Set Correct Pressure Settings: Adjust jockey, electric, and diesel pump cut-in/cut-out pressures according to NFPA standards.

Maintain Diesel Engines: Ensure diesel fire pumps are fueled, lubricated, and tested regularly.

Train Personnel: Facility staff should be familiar with the start-up sequence and manual shutdown procedure.

Document System Settings: Keep detailed records of settings, test results, and maintenance activities.

The correct fire pump start-up sequence—jockey pump first, electric fire pump second, and diesel engine fire pump third—is the cornerstone of reliable fire protection. This sequence ensures smooth pressure maintenance, efficient response during fire emergencies, and compliance with NFPA 20 standards.

By understanding and implementing the correct start-up sequence, facility managers, fire safety professionals, and contractors can rest assured that their fire protection systems will perform flawlessly when needed most.