Fire-fighting pumps are critical components in fire protection systems, designed to deliver consistent water pressure to sprinklers, hydrants, and other fire suppression equipment during emergencies. However, for a fire pump to work efficiently, it must be properly primed. Without proper priming, the pump may run dry, cause cavitation, overheat, and ultimately fail when needed most.

In this article, we’ll explain what pump priming is, why it’s essential, and provide a detailed step-by-step guide on how to prime a fire-fighting pump correctly. We’ll also cover common issues, troubleshooting tips, and preventive measures to maintain optimal pump performance.

Priming is the process of removing air from the pump casing and suction line, replacing it with water to ensure the pump operates correctly. Since most fire-fighting pumps, especially centrifugal fire pumps, cannot pump air, the impeller must be surrounded by water to generate pressure and flow.

When a pump is not properly primed, the trapped air prevents the pump from drawing water from the source, resulting in loss of suction and failure to deliver water during an emergency.

Proper priming is crucial for ensuring a fire pump operates efficiently and reliably. Some key reasons include:

Ensures consistent water supply: Without water in the casing, the pump cannot create suction.

Prevents pump damage: Running dry can overheat the impeller and mechanical seals.

Maintains system readiness: Fire pumps must be ready to operate instantly in emergencies.

Avoids cavitation issues: Air pockets can cause vibration, noise, and reduced pump life.

Not all fire pumps require the same priming method. The priming procedure depends on the pump design:

End-Suction Centrifugal Fire Pumps

Require manual or automatic priming if installed above the water source.

Horizontal Split-Case Fire Pumps

Typically require priming when positioned above the suction source.

Vertical Turbine Fire Pumps

Generally self-priming since the impellers are submerged in water.

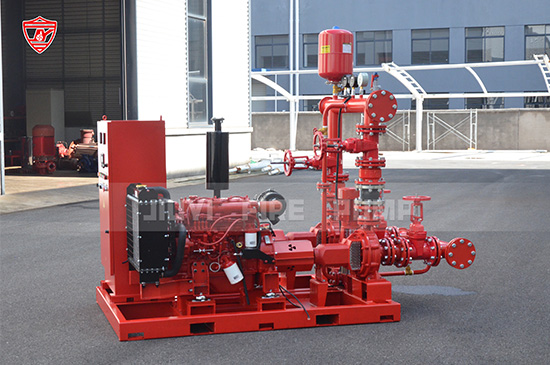

Diesel Engine Fire Pumps

Require additional care to ensure the pump casing is primed before engine startup.

Follow these steps carefully to prime a fire-fighting pump safely and effectively:

Ensure all valves, hoses, and suction lines are properly connected.

Check for leaks in the suction line and casing.

Confirm that the water source is available and at the correct level.

Always start with the discharge valve closed to reduce initial load on the pump.

This allows the casing to fill with water without immediate pressure loss.

Open the priming port or fill plug on top of the pump casing.

Pour clean water into the casing until it is completely full.

If available, use a priming pump or vacuum priming system for faster filling.

Loosen the air release valve or vent plug on the pump casing.

Allow air to escape until water flows steadily without bubbles.

Close the vent tightly to prevent air from re-entering.

Ensure the suction pipe is fully submerged in the water source.

If not, reposition the hose or lower the strainer to prevent air intake.

Start the electric motor or diesel engine.

Monitor pressure gauges to confirm water is flowing smoothly.

Keep an eye on the suction gauge to ensure there’s no air leakage.

Slowly open the discharge valve to avoid sudden pressure surges.

Ensure the system reaches the required operating pressure.

Even with proper priming, you may encounter issues. Here are some common problems and solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Pump won’t prime | Air leak in suction line | Tighten fittings, replace gaskets |

| No water flow after priming | Suction pipe not submerged | Lower strainer or reposition hose |

| Excessive vibration or noise | Air trapped in casing | Bleed air using vent valve |

| Pump loses prime repeatedly | Foot valve failure | Inspect and replace faulty foot valve |

| Overheating during priming | Pump running dry | Stop pump, refill casing, and restart |

Always keep the pump casing filled: Check water levels regularly.

Use a foot valve or check valve: Prevents backflow and loss of prime.

Install a vacuum priming system: Especially useful for diesel-driven fire pumps.

Perform routine inspections: Identify leaks or worn seals early.

Train your personnel: Ensure operators know correct priming procedures.

Diesel engine fire pumps require extra attention since they typically operate in remote installations or during power failures. Key tips include:

Always prime the pump before engine startup.

Check the engine’s cooling system to avoid overheating.

Use an automatic priming system for faster response in emergencies.

Perform regular weekly test runs to ensure readiness.

Regular maintenance reduces priming issues and ensures the fire pump is always operational:

Weekly: Inspect pump casing, suction lines, and valves.

Monthly: Test priming functionality and check for leaks.

Quarterly: Clean strainers and verify check valve performance.

Annually: Conduct a full performance test under NFPA 25 guidelines.

Priming a fire-fighting pump is a critical step in ensuring reliable fire protection. Whether you’re working with an electric motor-driven pump, diesel engine pump, or vertical turbine pump, proper priming guarantees consistent water flow and protects your equipment from damage.

By following the step-by-step procedure, troubleshooting common issues, and performing regular preventive maintenance, you can ensure your fire pump remains ready to perform when it matters most.