Ensuring your fire pump is operating properly is critical for maintaining a reliable fire protection system. A malfunctioning pump can compromise the entire safety of your building, putting lives and property at risk. Whether you’re responsible for commercial facilities, industrial sites, or residential complexes, regular fire pump checks are essential.

In this article, we’ll walk you through how to check if a fire pump is working, key inspection steps, common signs of malfunction, testing methods, and preventive maintenance practices based on industry standards like NFPA 20 and NFPA 25.

Fire pumps are the heart of a fire protection system. Their role is to supply adequate water pressure to sprinklers, hydrants, and hose reels during a fire emergency. If the pump fails when needed, the entire fire suppression system becomes ineffective.

Key reasons to perform regular fire pump checks:

Life Safety – Ensures sufficient water pressure during emergencies.

Compliance – Meets NFPA 25 and local fire safety regulations.

System Reliability – Identifies issues before they escalate.

Cost Savings – Prevents expensive breakdowns and emergency repairs.

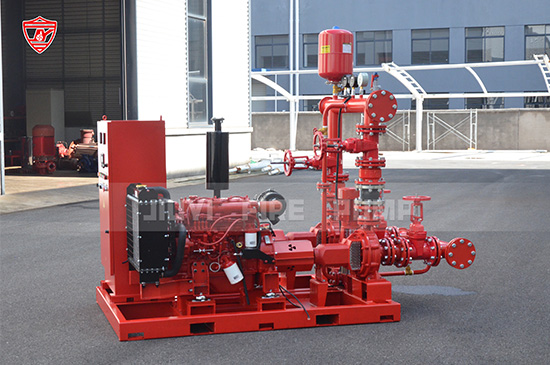

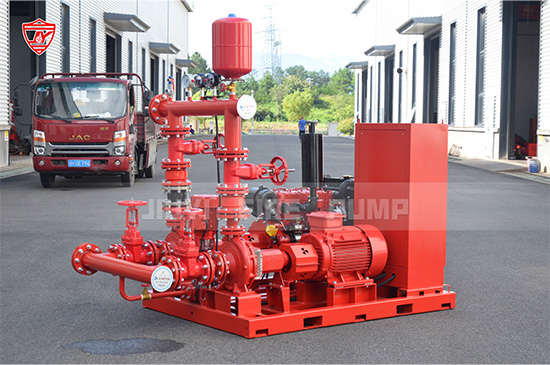

Before testing a pump, it’s important to understand what type of pump you have. Fire pumps operate differently depending on their design, so testing methods can vary.

Electric Fire Pumps – Require checking electrical controls, motor function, and power supply stability.

Diesel Engine Fire Pumps – Require additional inspection of fuel systems, batteries, and cooling mechanisms.

Vertical Turbine Fire Pumps – Often used in areas with limited water pressure; require specific shaft and bearing checks.

Jockey Pumps – Maintain system pressure and require regular function testing.

Knowing the pump type ensures you follow the correct inspection procedures.

Below is a step-by-step guide to inspecting your fire pump effectively.

Start with a thorough visual check:

Look for oil leaks, loose connections, and signs of corrosion.

Check the pump casing and couplings for damage.

Ensure suction and discharge valves are fully open and functional.

Inspect gauges for abnormal readings.

For electric pumps, verify the power source and inspect starter panels.

For diesel pumps, check battery voltage, fuel level, and coolant.

Test the controller indicators to ensure the pump can start automatically.

You can perform a churn test to verify basic functionality:

Start the pump manually using the control panel.

Observe the pump running without discharging water.

Listen for abnormal noises or vibrations.

Check suction pressure and discharge pressure using installed gauges.

Compare readings to the pump’s rated performance curve.

Low discharge pressure may indicate impeller damage, clogged strainers, or suction issues.

A flow test confirms the pump’s actual capacity:

Connect hoses to the test header or hydrants.

Measure the flow rate and compare it to the manufacturer’s specifications.

Ensure the pump delivers adequate pressure under load conditions.

Knowing the warning signs of malfunction can prevent unexpected failures:

Sudden drops in water pressure.

Excessive noise or vibration during operation.

Frequent controller alarms or error codes.

Diesel pump failing to start due to battery or fuel issues.

Tripped circuit breakers in electric fire pumps.

If you notice any of these issues, immediate troubleshooting is necessary.

The National Fire Protection Association (NFPA) recommends specific testing intervals under NFPA 25:

| Test Type | Frequency |

|---|---|

| Visual Inspection | Weekly |

| Churn Test | Weekly |

| Flow Test | Annually |

| Controller Test | Monthly |

| Diesel Engine Battery | Weekly |

| Jockey Pump Check | Weekly |

Following these guidelines ensures compliance and system readiness.

If your inspection reveals problems, here are common troubleshooting tips:

Low Pressure → Check for clogged strainers, air leaks, or worn impellers.

Pump Won’t Start → Inspect controller wiring, starter relays, or diesel batteries.

Unusual Vibration → Examine bearings, couplings, and shaft alignment.

Overheating → Check lubrication, cooling systems, and motor load.

If the issue persists, it’s best to involve a certified fire pump technician.

To ensure your fire pump stays reliable:

Keep a detailed maintenance log with inspection dates and findings.

Regularly lubricate bearings and rotating parts.

Replace worn-out gaskets, seals, and filters.

Conduct annual performance testing to validate rated capacity.

Train staff on emergency pump operation and testing procedures.

While basic checks can be performed in-house, professional servicing is essential if:

Performance test results deviate from manufacturer specifications.

Electrical or diesel control systems fail repeatedly.

NFPA compliance reports require certified validation.

Hiring qualified technicians ensures safety and protects your organization from liability.

Regularly checking your fire pump is critical for safety and compliance.

Start with a visual inspection, then test operation, pressure, and flow.

Follow NFPA 25 testing schedules for reliability.

Address minor issues promptly to avoid major failures.

Combine in-house checks with professional servicing for optimal performance.

A properly functioning fire pump is the backbone of any fire protection system. By performing regular inspections, testing pump performance, and following preventive maintenance practices, you can ensure your fire pump is always ready to perform during an emergency.

If you’re managing a facility where fire safety is critical, adopting these practices will help you maintain compliance, reduce downtime, and protect both people and property.