Water hammer is one of the most common yet underestimated problems in fire pump systems. While often associated with municipal or industrial piping, water hammer can cause serious mechanical stress, system failure, and long-term reliability issues in fire protection systems if not properly addressed.

As a fire pump manufacturer, we frequently see water hammer-related damage during commissioning, testing, or even emergency operation. Understanding why water hammer occurs and how to prevent it is essential for engineers, contractors, and facility owners who want a reliable and code-compliant fire pump system.

This article explains what water hammer is, why it occurs in fire pump systems, and most importantly, how to prevent it through correct design, equipment selection, and operational practices.

What Is Water Hammer?

Water hammer is a pressure surge or shock wave that occurs when the flow of water is suddenly stopped or changed. This sudden change in velocity generates a high-pressure wave that travels through the piping system at high speed.

In fire pump systems, water hammer is especially dangerous because:

-

Operating pressures are already high

-

Pipe diameters are large

-

Valves and pumps operate under emergency conditions

-

System reliability is critical for life safety

If not controlled, water hammer can result in pipe rupture, joint failure, damaged valves, pump seal failure, and premature wear of system components.

Why Water Hammer Occurs in Fire Pump Systems

Fire pump systems have unique operating characteristics that make them more vulnerable to pressure surges.

Sudden Pump Start or Stop

Fire pumps are designed to start automatically when system pressure drops. A rapid pump start can instantly accelerate a large volume of water, creating a pressure spike. Similarly, an abrupt pump stop can cause reverse flow and a strong pressure wave.

Fast-Closing Valves

Deluge valves, control valves, and test header valves that close too quickly can abruptly stop water flow, triggering water hammer. This is particularly common during weekly or monthly pump testing.

Improper Check Valve Selection

Check valves that slam shut instead of closing smoothly can cause severe pressure surges, especially in vertical or high-flow installations.

Long and Rigid Piping Runs

Long straight pipe runs without flexibility or surge absorption allow pressure waves to travel farther and with greater intensity.

High System Pressure and Flow Rates

Fire pumps operate at high flow rates and pressures. Any sudden hydraulic change under these conditions amplifies the impact of water hammer.

Why Preventing Water Hammer Is Critical in Fire Safety

Water hammer is not just a noise issue. In fire protection systems, it directly affects safety and compliance.

-

Structural damage to pipes and fittings

-

Leakage at flanges and joints

-

Damage to fire pump bearings and mechanical seals

-

Failure of pressure sensors and gauges

-

Reduced system lifespan

-

Increased maintenance and downtime

-

Potential non-compliance with fire codes and standards

Preventing water hammer is an essential part of ensuring that the fire pump system performs reliably when it is needed most.

Design Strategies to Prevent Water Hammer

Effective water hammer prevention starts at the design stage of the fire pump system.

Proper Pipe Sizing

Undersized piping increases water velocity, which directly increases the severity of pressure surges. Correct pipe sizing reduces flow velocity and minimizes shock intensity.

Designers should:

-

Follow hydraulic calculations carefully

-

Avoid excessive velocity in suction and discharge piping

-

Consider future system expansion when sizing pipes

Optimized System Layout

Sharp bends, sudden diameter changes, and long straight runs can worsen water hammer effects.

Best practices include:

-

Minimizing abrupt directional changes

-

Using gradual transitions for pipe diameter changes

-

Avoiding unnecessarily long straight discharge runs

-

Adding flexibility in piping where possible

Adequate System Restraint

Fire protection piping must be properly supported and restrained. Unrestrained piping can move violently during pressure surges, increasing the risk of mechanical failure.

Correct Fire Pump Selection

Choosing the right fire pump plays a major role in water hammer prevention.

Matching Pump Performance to System Demand

Oversized pumps can generate excessive flow and pressure, increasing the likelihood of water hammer.

A properly selected fire pump should:

-

Match the system’s required flow and pressure

-

Operate efficiently within its performance curve

-

Avoid excessive pressure beyond system needs

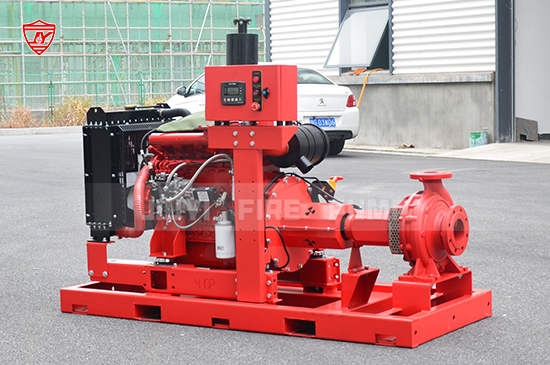

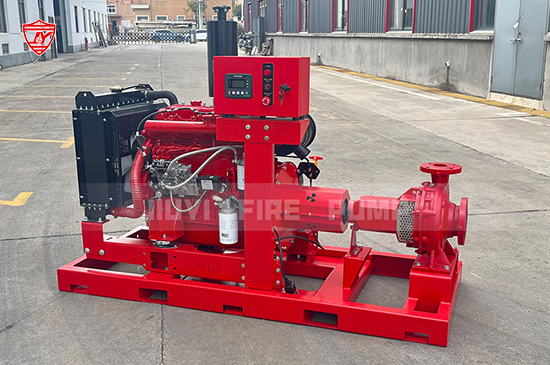

Electric vs Diesel Fire Pumps

Both electric and diesel fire pumps can cause water hammer if not correctly integrated into the system.

Diesel fire pumps require special attention due to:

-

Rapid torque application at startup

-

Engine-driven acceleration characteristics

-

Potential for delayed shutdown behavior

Proper control logic and valve selection are critical for both types.

Valve Selection and Installation Best Practices

Valves are one of the most common sources of water hammer in fire pump systems.

Use Non-Slam Check Valves

Traditional swing check valves can slam shut when flow reverses, creating severe pressure spikes.

Non-slam or silent check valves:

-

Close smoothly before flow reversal

-

Reduce pressure surge intensity

-

Improve overall system stability

These valves are highly recommended for fire pump discharge piping.

Control Valve Closing Speed

Valves that close too quickly should be avoided. Where possible:

-

Use valves with controlled closing mechanisms

-

Avoid manual operation that results in sudden closure

-

Train personnel on gradual valve operation during testing

Fire Pump Controller and System Controls

Fire pump controllers play a critical role in managing startup and shutdown behavior.

Controlled Startup

Although fire pumps must start quickly during emergencies, controlled acceleration can help reduce sudden pressure spikes. Modern controllers allow better control of startup sequences without compromising safety.

Proper Shutdown Sequencing

Abrupt shutdown is a common cause of water hammer. Proper shutdown logic should:

-

Prevent sudden loss of flow

-

Coordinate with system pressure conditions

-

Avoid unnecessary stop-start cycling

Use of Surge Mitigation Devices

In systems with high risk of water hammer, additional protective devices may be necessary.

Surge Tanks and Accumulators

Surge tanks absorb pressure spikes by temporarily storing excess energy from the pressure wave.

They are especially useful in:

-

Large fire pump installations

-

High-rise buildings

-

Long-distance piping systems

Air Chambers

Properly designed air chambers can cushion pressure surges. However, they must be correctly sized and maintained to remain effective.

Installation Quality and Commissioning

Even the best design can fail if installation quality is poor.

Proper Alignment and Anchoring

Misaligned pipes and poorly anchored components are more susceptible to damage from pressure surges.

Gradual Commissioning and Testing

During system commissioning:

-

Slowly introduce flow

-

Avoid sudden valve operation

-

Monitor pressure fluctuations carefully

Testing procedures should replicate real operating conditions while minimizing shock loads.

Maintenance and Operational Practices

Ongoing maintenance is essential to prevent water hammer over the life of the system.

Regular Valve Inspection

Worn or damaged valves may not close properly, increasing surge risk.

Monitoring System Pressure Behavior

Unusual pressure spikes, vibration, or noise should be investigated immediately.

Training Operating Personnel

Operators should understand:

-

The causes of water hammer

-

Proper valve operation techniques

-

Safe testing and shutdown procedures

Human factors play a major role in preventing water hammer incidents.

Compliance with Fire Safety Standards

Fire pump systems must comply with recognized fire safety standards. While these standards focus on performance and reliability, they also emphasize proper system design and installation that indirectly reduce water hammer risks.

Adhering to recognized standards ensures:

-

Proper component selection

-

Safe operating margins

-

Long-term system reliability

Conclusion

Preventing water hammer in fire pump systems is not a single action but a comprehensive approach involving system design, pump selection, valve choice, control logic, installation quality, and ongoing maintenance.

For fire protection systems, reliability is non-negotiable. A well-designed and properly installed fire pump system that addresses water hammer risks will not only protect equipment investment but also ensure dependable performance during critical fire emergencies.

As a fire pump manufacturer, we strongly recommend addressing water hammer prevention early in the design stage and maintaining best practices throughout the system’s entire lifecycle. This proactive approach results in safer, quieter, and more durable fire pump installations that perform when it matters most.