Diesel fire pumps are critical life-safety equipment designed to operate reliably during emergencies, often under the most demanding conditions. When a diesel fire pump fails to start, the consequences can be severe—property loss, system non-compliance, and most importantly, risks to human life. Despite being robust and independent from electrical power, diesel fire pumps are not immune to failure. In most cases, starting failure is not caused by design flaws, but by preventable issues related to maintenance, installation, testing, or operational oversight.

This article offers a comprehensive and practical guide on how to prevent diesel fire pump starting failure, drawing on real-world manufacturing experience and industry best practices. Whether you are a fire protection contractor, facility manager, consultant, or system owner, understanding these factors will significantly improve system reliability and compliance.

A diesel fire pump starting failure generally refers to any condition where the engine does not crank, cranks but does not start, or starts but immediately shuts down when required to operate. Common scenarios include failure during automatic start, delayed response, insufficient engine speed, or shutdown caused by protective alarms.

It is important to understand that diesel fire pump engines are designed differently from standard industrial engines. They must start instantly, reach rated speed quickly, and operate continuously under load. Any weakness in supporting systems—fuel, battery, cooling, air intake, or controls—can result in failure at the worst possible moment.

Fuel-related problems are one of the leading causes of diesel fire pump starting failure.

Contaminated fuel, such as diesel mixed with water, sediment, or microbial growth, can clog injectors and fuel filters. Over time, stored diesel degrades, especially in warm or humid environments. Facilities that rarely test or run their fire pump are particularly vulnerable to this issue.

Another common problem is insufficient fuel supply. This may be caused by low fuel levels, blocked fuel lines, air trapped in the system, or improperly sized fuel piping. Even a partially closed fuel valve can prevent the engine from starting.

To prevent fuel-related failures, diesel quality must be regularly monitored. Fuel tanks should be inspected, drained of water, and cleaned periodically. Fuel filters must be replaced according to manufacturer recommendations, and fuel valves should always be locked in the open position.

Although diesel fire pumps do not rely on external power to operate, they depend heavily on batteries to start. Weak, discharged, or improperly maintained batteries are a major cause of starting failure.

Batteries naturally lose capacity over time, even if the pump is rarely used. Corroded terminals, loose connections, damaged cables, or faulty chargers can prevent sufficient current from reaching the starter motor. In cold environments, battery performance degrades even faster.

Most standards require dual battery systems to ensure redundancy, but redundancy does not help if both batteries are poorly maintained. Batteries must be load-tested regularly, terminals cleaned, electrolyte levels checked where applicable, and chargers verified for correct output voltage.

A diesel fire pump that cranks slowly or inconsistently is often signaling battery or starter issues long before a complete failure occurs.

Cooling systems play a critical role even before the diesel engine starts. Engines equipped with jacket water heaters rely on proper coolant temperature to allow quick and reliable ignition.

If the jacket water heater fails, coolant temperature may drop too low, especially in cold climates. Cold engines require more cranking power, experience incomplete combustion, and may fail to start altogether.

Cooling system issues can also include low coolant levels, air trapped in the system, blocked circulation, or heater power supply failure. These issues are often overlooked because the engine appears idle and unused.

Regular verification of coolant temperature, heater operation, and coolant quality is essential to ensure reliable starting conditions at all times.

A diesel engine requires a consistent and unrestricted air supply to start and run properly. Blocked air filters, collapsed intake hoses, or closed dampers can severely restrict airflow.

In some installations, exhaust systems may accumulate soot, condensation, or corrosion over time. Improper exhaust routing or rainwater intrusion can create back pressure that prevents the engine from starting or causes it to stall shortly after startup.

Routine inspection of air filters, intake piping, and exhaust components is often neglected, yet it is a simple and effective way to prevent starting failures.

Modern diesel fire pump systems rely on controllers to manage automatic starting, alarms, and safety functions. Incorrect settings, wiring faults, sensor failures, or control logic errors can prevent the engine from receiving a start signal.

Common issues include failed pressure switches, loose wiring connections, blown fuses, or disabled automatic modes after maintenance work. In some cases, alarm interlocks may incorrectly shut down the engine due to faulty signals.

Control panels should be inspected and tested by qualified personnel. All alarms, indicators, and automatic start functions must be verified during routine testing. Any modification to control logic should be documented and validated to ensure compliance with applicable standards.

One of the most overlooked causes of diesel fire pump starting failure is simple inactivity. Fire pumps that are rarely exercised are far more likely to fail than those tested regularly.

Without routine operation, fuel degrades, seals dry out, batteries discharge, and mechanical components lose lubrication. Small problems remain hidden until an emergency occurs.

Weekly or monthly test runs allow operators to detect abnormal sounds, slow cranking, unstable speed, alarm conditions, or leaks. These early warning signs are invaluable in preventing catastrophic failure.

A structured preventive maintenance program should include starting tests, load testing when required, visual inspections, and documentation of all findings.

Environmental conditions have a significant impact on diesel fire pump reliability. Excessive heat, high humidity, dust, vibration, or corrosive atmospheres accelerate component degradation.

Improper installation can also contribute to starting failure. Common installation-related issues include undersized fuel lines, inadequate ventilation, poor grounding, insufficient clearance for maintenance, or exposure to flooding.

Ensuring that the pump room meets design requirements for ventilation, temperature control, drainage, and accessibility is just as important as maintaining the pump itself.

Even the most advanced diesel fire pump system can fail due to human error. Examples include accidentally switching controllers to manual mode, leaving battery chargers disconnected, closing fuel valves after maintenance, or ignoring alarm warnings.

Clear operating procedures, proper training, and responsibility assignment are critical. Operators should understand not only how to test the pump, but also why each system component matters.

Documentation, checklists, and maintenance logs help reduce the risk of oversight and ensure continuity when personnel change.

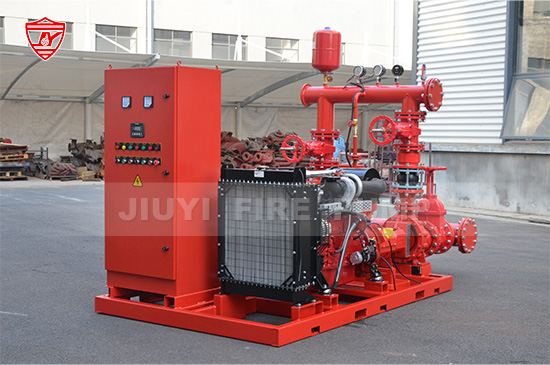

From a manufacturer’s perspective, preventing diesel fire pump starting failure begins at the design and production stage. Proper engine selection, redundant systems, high-quality components, factory testing, and clear documentation all contribute to long-term reliability.

However, even the best-designed fire pump requires correct installation, operation, and maintenance. Collaboration between manufacturers, contractors, and end users is essential to achieve reliable fire protection performance.

Diesel fire pump starting failure is rarely sudden or unpredictable. In most cases, it is the result of small, preventable issues accumulating over time. Fuel quality, battery condition, cooling systems, air supply, control logic, and regular testing all play critical roles in ensuring dependable operation.

Preventing starting failure is not about reacting to problems—it is about building a culture of prevention, inspection, and accountability. When properly maintained and operated, a diesel fire pump will perform exactly as intended when it is needed most.

For fire safety professionals, system owners, and facility managers, investing time and resources into preventive measures is not optional. It is a responsibility that protects lives, property, and compliance.