Fire pumps are the heart of a building’s fire protection system. Whether installed in commercial complexes, industrial facilities, or high-rise buildings, they play a critical role in delivering adequate water pressure during emergencies. To ensure reliability, annual fire pump inspections are not just a regulatory requirement—they are essential for safeguarding lives and property.

In this article, we’ll explain how to prepare for an annual fire pump inspection, what inspectors look for, the key NFPA 25 compliance requirements, and how proactive maintenance can minimize downtime and costly repairs.

Annual fire pump inspections are mandated by NFPA 25, the standard for the inspection, testing, and maintenance of water-based fire protection systems. Proper preparation ensures:

Regulatory compliance with local fire codes and insurance requirements

System reliability during emergencies

Cost savings by avoiding unexpected failures and downtime

Extended equipment lifespan through early issue detection

For facility managers, understanding the inspection process is critical for keeping systems operational and avoiding penalties.

According to NFPA 25, fire pumps must undergo weekly, monthly, and annual inspections. While weekly and monthly checks are often handled in-house, the annual inspection is typically performed by certified fire protection professionals.

Key NFPA 25 annual requirements include:

Flow Testing – Measures the pump’s performance under different flow conditions.

Controller Inspection – Verifies proper function of electric or diesel controllers.

Pressure Relief Valve Check – Ensures the valve operates correctly under high-pressure scenarios.

Suction and Discharge Piping Inspection – Checks for leaks, corrosion, or obstructions.

Driver Operation Test – Confirms that the electric motor or diesel engine operates smoothly.

System Integration Check – Ensures the pump responds properly to automatic fire detection systems.

Pro Tip: Keep a copy of the latest NFPA 25 standard available for your maintenance team to cross-check requirements.

Before the annual inspection, preparing your fire pump system properly can save time and prevent failed inspections.

Maintain updated maintenance records and test reports from previous inspections.

Keep the fire pump’s operation and maintenance manuals accessible.

Prepare proof of any recent repairs or upgrades.

Check for visible leaks, corrosion, or loose fittings.

Ensure gauges, valves, and meters are clearly labeled and functional.

Verify that suction strainers and screens are clean and unobstructed.

Test batteries in electric or diesel controllers.

Confirm that control panels are free from dust, moisture, and obstructions.

Ensure automatic start features are operational.

Check fuel tank levels and quality.

Inspect engine oil, coolant, and belts.

Verify exhaust systems are intact and compliant with safety standards.

Confirm adequate water supply from city mains or storage tanks.

Ensure isolation valves are fully open and tagged appropriately.

Check for obstructions or sediment buildup in suction piping.

Fire pump inspectors will evaluate several system components to ensure compliance and performance readiness:

Inspectors conduct flow tests to confirm that the fire pump achieves required pressure and flow rates as per NFPA 25.

Inspectors ensure that low-pressure alarms, power-failure signals, and pump-start notifications are functioning correctly.

Testing verifies that the pump starts automatically when system pressure drops and shuts down properly when no longer needed.

Relief valves, temperature sensors, and emergency shutdown systems are checked to ensure quick response during abnormal conditions.

Even well-maintained systems can fail inspection due to overlooked issues. Some common findings include:

Corroded pipes or pump casings reducing efficiency

Clogged suction strainers affecting water flow

Battery failures in electric or diesel controllers

Worn impellers or bearings reducing pump performance

Improper valve positions causing system malfunctions

Proactive Tip: Addressing these issues during routine maintenance prevents costly repairs and downtime during inspections.

Schedule regular checks beyond NFPA 25’s minimum requirements to catch potential issues early.

Ensure that your in-house team understands NFPA 25 requirements and fire pump operation basics.

Working with an experienced fire pump manufacturer or service provider ensures your system meets performance standards.

Once the annual inspection is completed:

Review the inspection report carefully and understand any noted deficiencies.

Schedule necessary repairs immediately to remain compliant.

Update documentation with new test results for future reference.

Communicate findings with stakeholders, facility managers, and insurance providers if required.

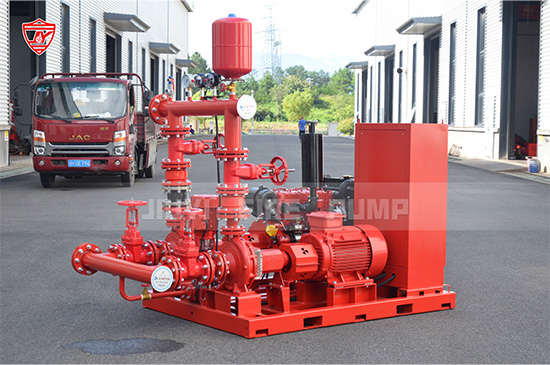

As a leading manufacturer of UL/FM-approved fire pumps, Better Technology Group provides complete support for:

Fire pump selection and sizing

NFPA 20 and NFPA 25 compliance consulting

Preventive maintenance solutions

On-site performance testing and system troubleshooting

Our vertical turbine, electric, and diesel fire pumps are designed for reliability, compliance, and performance—making your annual inspections smoother and stress-free.

Preparing for annual fire pump inspections is not just about passing a test; it’s about ensuring fire safety readiness and system reliability. By following NFPA 25 guidelines, maintaining accurate records, and working with certified professionals, you can keep your fire pump system operating at peak efficiency year-round.