Proper ventilation in a fire pump room is one of the most critical yet often overlooked aspects of a reliable fire protection system. Whether the system uses an electric motor or a diesel engine fire pump, inadequate ventilation can lead to overheating, equipment failure, or even non-compliance with fire protection standards.

In this article, we’ll discuss why ventilation matters, the key requirements from standards like NFPA 20, and the best practices to design, install, and maintain an effective ventilation system for fire pump rooms.

The fire pump room houses equipment that must operate at peak performance during an emergency. High temperatures, insufficient air exchange, or poor exhaust management can reduce the system’s reliability.

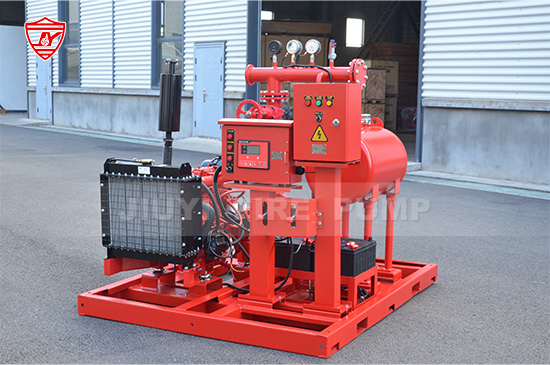

For diesel engine fire pumps, ventilation plays an even greater role. These engines generate substantial heat during operation and require fresh air for combustion. Inadequate ventilation can cause power loss, engine stalling, and even premature wear of components.

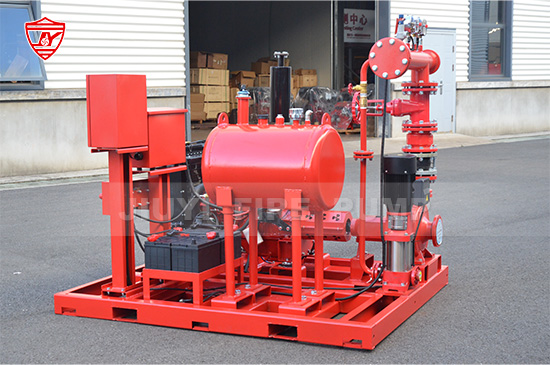

For electric motor fire pumps, excessive heat buildup can degrade insulation and shorten motor lifespan. Moreover, a poorly ventilated room can affect control panels, sensors, and other electrical components sensitive to temperature and humidity.

In short, ventilation is not just about comfort—it’s about maintaining reliability, performance, and compliance.

NFPA 20, the standard for the installation of stationary fire pumps, provides detailed guidance on ventilation for both electric motor and diesel engine-driven fire pumps.

Here are the key points to consider:

Maintain Safe Operating Temperatures

The ambient temperature in the fire pump room should not exceed 120°F (49°C).

This ensures that both electrical and mechanical components function safely during pump operation.

Air Supply for Combustion (Diesel Pumps)

Diesel engines require sufficient air for both combustion and cooling.

The inlet opening should provide at least 1 in² of free area per 2730 BTU/hr of engine output.

Exhaust Air Removal

Exhaust gases must be safely vented outside, away from air intakes and nearby buildings.

Proper routing prevents recirculation of hot exhaust air into the room.

Emergency Operation Conditions

The ventilation system must operate automatically when the fire pump runs.

Even during power failure, diesel-driven pumps require ventilation to maintain air quality and temperature.

Intake and Exhaust Placement

Openings should be positioned to promote cross-ventilation: intake low, exhaust high.

Louvers and dampers should not obstruct airflow during operation.

Compliance with NFPA 20 ensures that the fire pump system can function reliably under real fire conditions without the risk of overheating or failure.

Designing an effective fire pump room ventilation system involves balancing air intake, exhaust, and temperature control. Each project may vary depending on room size, location, and the type of fire pump used.

Start by evaluating the fire pump room’s physical dimensions and layout.

The room should have enough space for air movement around the pump, engine, and controller.

Avoid placing the pump too close to walls or corners where heat can be trapped.

Calculate the airflow required to maintain safe temperature levels.

For diesel engines, calculate both combustion and cooling air requirements.

For electric pumps, consider the heat dissipated by the motor and electrical panels.

Ensure sufficient air changes per hour to remove generated heat effectively.

Strategically position air inlets and outlets for efficient airflow.

Inlets should bring in cool air from outside.

Exhaust openings should discharge hot air outdoors without recirculation.

If natural ventilation isn’t possible, install mechanical fans.

When mechanical ventilation is needed, fan sizing becomes crucial.

Select fans that can handle high temperature and continuous operation.

Use corrosion-resistant materials if the environment is humid or salty.

Provide redundancy where reliability is critical.

Humidity control is essential, especially in coastal or tropical regions.

Use dehumidifiers or ventilation with filters to reduce moisture.

Prevent condensation inside electrical panels and control cabinets.

Insulate walls and ceilings to reduce temperature fluctuations.

Diesel engine exhaust and fans can produce significant noise.

Use silencers and vibration isolators to protect nearby occupied areas.

Follow local environmental noise regulations.

Diesel-driven fire pumps have specific ventilation needs because of heat generation and exhaust gases.

Key points to remember:

Fresh Air for Combustion: Ensure adequate airflow to supply oxygen for engine combustion.

Exhaust Gas Routing: Exhaust pipes must be directed outside with proper insulation to prevent radiant heat.

Cooling Airflow: Hot air should be expelled efficiently to avoid heat buildup.

Backup Power Ventilation: If an auxiliary fan depends on electrical power, it must be connected to the emergency power source to ensure operation during a fire event.

It’s best to provide at least two separate openings—one for air intake and one for exhaust—to create a continuous air path through the room.

Although electric pumps produce less heat, ventilation remains important to keep the room temperature stable and protect sensitive components.

Recommendations include:

Install natural or forced ventilation to maintain temperature below 40°C (104°F).

Ensure motor control panels have adequate airflow to avoid overheating.

Use dust filters or screens if the fire pump room is near an industrial area.

Avoid placing the electric motor directly under sunlight or near other heat sources.

Even well-designed systems can fail due to simple mistakes. Below are some common issues that compromise ventilation performance:

Undersized Air Openings

Small inlets or exhaust vents can restrict airflow, leading to excessive temperature rise.

Poor Exhaust Routing

Exhaust pipes located too close to air intakes can cause recirculation of hot gases.

Neglecting Fan Maintenance

Dust accumulation, worn bearings, or damaged louvers can drastically reduce ventilation efficiency.

Ignoring Seasonal Variations

Changes in outdoor temperature or humidity can affect air density and ventilation performance.

No Automatic Control

Ventilation fans should operate automatically when the fire pump starts, ensuring immediate cooling.

Routine inspection and maintenance are vital for long-term reliability. Include ventilation systems in your fire pump maintenance checklist:

Inspect louvers and grilles monthly for blockage or corrosion.

Check fan motors, belts, and bearings regularly.

Verify that automatic start functions are working correctly.

Measure room temperature during test runs to ensure compliance with NFPA 20 limits.

Clean filters and air ducts as part of your periodic maintenance schedule.

Ventilation should not be viewed as an isolated feature but as an integrated part of the fire pump system. Combining proper ventilation with regular testing, environmental monitoring, and preventive maintenance helps extend the lifespan of the fire pump and ensures that it performs reliably during emergencies.

For facilities operating multiple fire pumps or large pump rooms, consider installing temperature sensors and automatic control systems that adjust fan speed based on real-time room conditions.

Proper ventilation in a fire pump room is essential to maintain safe operation, ensure compliance with NFPA 20, and protect equipment from heat damage. Both diesel and electric fire pumps depend on controlled air circulation to deliver consistent performance when it matters most.

By following the design guidelines, understanding standard requirements, and conducting regular maintenance, building owners and engineers can create a fire pump room that operates efficiently, safely, and in full compliance with global fire protection standards.

In fire safety, reliability is everything—and good ventilation is a key part of that reliability.