A Complete Guide for Fire Protection Professionals

Fire pumps are the backbone of your building’s fire protection system. When these vital systems show signs of trouble—leaks, vibrations, reduced pressure—facility managers often face a critical question: Should we repair or replace the fire pump?

This decision has serious implications for life safety, regulatory compliance, and long-term costs. As a professional fire pump manufacturer, we’ve helped thousands of customers navigate this decision with confidence. In this article, we’ll walk you through how to evaluate your fire pump’s condition, understand industry standards, compare cost factors, and determine the right course of action for your specific situation.

A malfunctioning or underperforming fire pump can jeopardize lives and property during a fire emergency. Delaying replacement when it’s truly needed can result in:

Failure to meet NFPA 25 maintenance requirements

Non-compliance with insurance or AHJ standards

Reduced water pressure or flow during a fire

Catastrophic system failure in an emergency

On the other hand, premature replacement of a pump that could be repaired might mean unnecessary expenses and extended downtime.

Most fire pumps, when properly maintained, can last 15–25 years or longer. However, several factors can shorten their useful life:

Poor water quality (corrosion, debris)

Inadequate maintenance

Cavitation damage

Overloading or running dry

Improper installation

Electric fire pumps tend to have a longer lifespan than diesel engine fire pumps, which experience more wear due to moving parts and fuel combustion.

Whether you repair or replace often starts with identifying warning signs. Key indicators include:

Unusual noises or vibration

Drop in discharge pressure or flow rate

Frequent tripping of electric motor or controller

Visible corrosion or leakage

Overheating of bearings or motor

Excessive power consumption

Performing annual performance testing and weekly churn tests (as per NFPA 25) is essential for detecting these issues early.

Repairs may be the right choice if:

The pump is under 15 years old

Issues are limited to specific components (seals, bearings, impellers)

Repairs cost significantly less than replacement

There is no structural damage to the pump housing

There is no repeated history of failure

Examples of common repairable issues:

| Issue | Typical Repair |

|---|---|

| Shaft misalignment | Realignment and recalibration |

| Leaking seals | Replacement of mechanical seals |

| Worn impellers | Machining or replacing impeller |

| Motor overheating | Rewinding or replacing bearings |

Make sure all repairs follow OEM specifications and are tested after reinstallation.

Consider replacement if your pump has:

Extensive corrosion or pitting

Major performance drop (e.g., <70% rated flow)

Frequent failures despite past repairs

Obsolete components no longer supported by the OEM

High repair costs nearing or exceeding replacement value

System redesign requiring updated flow/pressure capacity

NFPA 20 and NFPA 25 do not mandate replacement based on age alone, but AHJs may recommend it after 25+ years or based on risk factors.

| Cost Factor | Repair | Replacement |

|---|---|---|

| Initial Cost | Lower | Higher |

| Downtime | Shorter (if parts are available) | Longer (design, install, test) |

| Long-Term Maintenance Costs | May increase if issues persist | Lower with new warranty and parts |

| Risk of Recurrence | Moderate | Minimal |

| Performance Improvements | Limited | Major efficiency & safety gains |

Before deciding, ask your fire pump vendor for a cost-benefit analysis comparing total repair cost and expected lifespan vs. new installation.

Authorities Having Jurisdiction (AHJs), building insurers, and safety inspectors often require:

Annual testing reports per NFPA 25

Maintenance logs for pumps older than 20 years

Evidence of compliance with UL/FM standards

If your pump frequently fails tests or cannot meet NFPA 20 design criteria, you may be required to upgrade.

Also, replacing with a UL Listed Fire Pump or NFPA 20-compliant package set can help reduce insurance premiums and enhance your facility’s safety profile.

If you determine that replacement is the right path, here’s how to do it right:

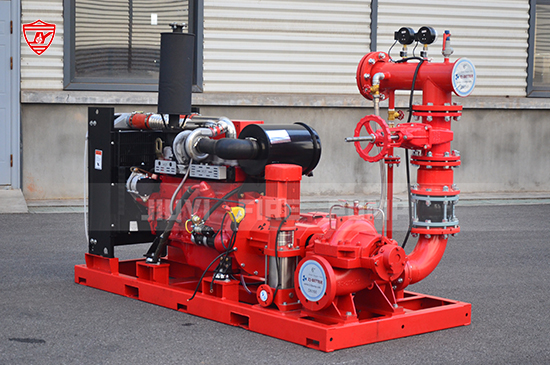

Choose the correct pump type (Electric, Diesel, Vertical Turbine, End Suction, etc.)

Match NFPA 20 requirements for your building size and hazard level

Work with certified professionals for sizing, design, and installation

Test post-installation with certified performance data

Train maintenance personnel on operation and periodic inspection

We offer turnkey fire pump packages, including UL Listed, diesel/electric units, jockey pumps, and full system design support to ensure compliance and reliability.

Ask yourself:

Is the pump over 20 years old?

Does it consistently fail performance tests?

Are parts becoming hard to find?

Have you repaired it more than once in the past year?

Are safety standards or system needs changing?

If you answer "yes" to two or more of the above, replacement is likely the more cost-effective and safer option.

A reliable fire pump is not just an asset—it’s a life-saving system. Knowing when to repair vs. replace a fire pump can reduce your liability, improve emergency readiness, and extend your fire system’s service life.

Still unsure?