In industrial facilities, where the stakes are high and the consequences of fire can be catastrophic, investing in a robust fire protection system is not just a regulatory requirement—it’s a critical part of risk management. One of the most vital components in any industrial fire protection system is the fire pump. Designed to ensure adequate water pressure during fire emergencies, fire pumps are key to improving industrial fire resilience.

In this article, we will explore the function, types, and strategic importance of fire pumps in industrial settings, along with how they contribute to operational continuity, personnel safety, and compliance with global fire safety standards like NFPA 20.

1. Understanding Fire Resilience in Industrial Settings

Fire resilience refers to the ability of a facility to prevent, withstand, and recover from a fire event with minimal disruption. This is especially important in industrial settings such as manufacturing plants, refineries, warehouses, and chemical facilities, where:

-

Fire loads are higher due to combustible materials

-

Damage can impact production and cause long downtimes

-

Regulatory consequences of non-compliance are severe

Fire pumps play a key role in ensuring that sprinklers, hydrants, and other suppression systems have the pressure and flow needed to function effectively in such high-risk environments.

2. What Is a Fire Pump and How Does It Work?

A fire pump is a critical component of a fire suppression system that delivers water at high pressure when the normal water supply is insufficient.

Fire Pump Working Principle:

-

Activated when pressure drops in the system (typically due to sprinkler or hydrant activation).

-

Draws water from a static source (like a water tank or underground reservoir).

-

Boosts pressure to meet the hydraulic requirements of the fire protection system.

Fire pumps are typically connected to one or more fire protection systems, including:

-

Sprinkler systems

-

Standpipe systems

-

Foam-water suppression systems

-

Water mist systems

3. Types of Fire Pumps Used in Industry

There are several types of fire pumps used in industrial applications, each suitable for different scenarios:

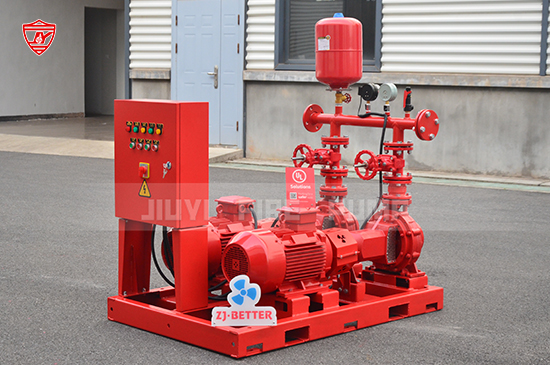

a. Electric Fire Pumps

-

Powered by a stable electrical supply

-

Ideal for facilities with reliable grid power

-

Lower maintenance compared to diesel pumps

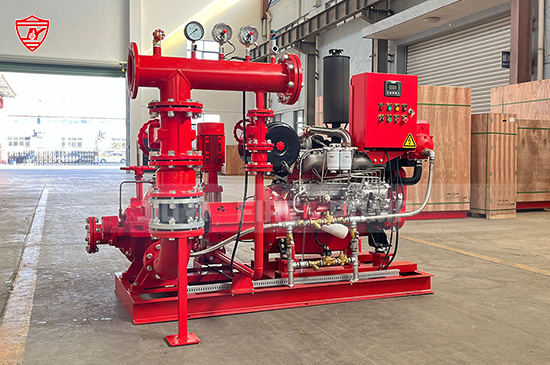

b. Diesel Engine Fire Pumps

-

Used when electrical power is unreliable or unavailable

-

Often required as a backup to electric pumps

-

Provide resilience in power outage situations

c. Jockey Pumps

-

Small pumps used to maintain system pressure and prevent unnecessary fire pump activation

-

Extend the lifespan of main fire pumps

d. Vertical Turbine Pumps

-

Used for deep well or below-grade water sources

-

Ideal for industrial sites with limited water tank space

e. UL Listed and NFPA 20 Compliant Pumps

-

Ensure that the system meets international safety and performance standards

-

Mandatory for many industrial facilities across the globe

4. Why Industrial Facilities Need Fire Pumps

1. High Water Pressure Requirements

Industrial fire protection systems require water at specific pressures. Municipal water supplies often cannot provide sufficient pressure, especially in multistory or expansive facilities.

2. Large Facility Coverage

Fire pumps ensure that every corner of the facility, no matter how large or remote, gets adequate water pressure.

3. Critical Safety Compliance

Fire pumps ensure that industrial sites meet codes such as:

-

NFPA 20 (Standard for the Installation of Stationary Pumps for Fire Protection)

-

FM Global and UL standards

-

Local fire and building codes

4. Operational Continuity

Quick and efficient fire response helps minimize damage and downtime, keeping operations running smoothly after incidents.

5. Benefits of Fire Pumps for Industrial Fire Resilience

a. Improved Emergency Response

Fire pumps ensure that suppression systems are always ready, reducing the time between fire detection and response.

b. Minimized Property Damage

By enabling high-performance suppression systems, fire pumps limit fire spread and associated property damage.

c. Enhanced Life Safety

They ensure a reliable supply of water for life-saving fire protection systems like sprinklers and hydrants.

d. Insurance Advantages

Facilities with compliant fire protection systems, including fire pumps, may qualify for lower insurance premiums.

e. Reduced Environmental Impact

By controlling fires more effectively, fire pumps help reduce the environmental damage caused by industrial fires and chemical spills.

6. Real-World Application Examples

Manufacturing Plant

A car parts manufacturing plant uses a UL-listed electric fire pump system connected to overhead sprinklers. This system was able to suppress a fire in a storage area before it could spread to production lines, minimizing damage and avoiding a two-week shutdown.

Oil & Gas Facility

A diesel fire pump with vertical turbine configuration ensures that water is delivered from a deep well during emergencies, even in case of a power outage, enabling continuous protection for hazardous zones.

7. Integration with Smart Fire Protection Systems

Modern industrial facilities are increasingly integrating fire pumps with building automation systems (BAS) and fire alarm panels. This integration provides:

-

Remote monitoring of pump status and performance

-

Automatic alerts in case of malfunction or pressure drops

-

Data logging for performance audits and inspections

Smart fire pump systems enhance response time, reduce manual inspection needs, and support predictive maintenance.

8. Maintenance and Testing of Fire Pumps

To ensure reliability, industrial fire pumps must be tested and maintained regularly. Recommended practices include:

-

Weekly no-flow tests (churn tests)

-

Monthly flow tests

-

Annual full-flow testing with calibrated instruments

-

Routine inspection of electrical systems, engines, controllers, and piping

Following NFPA 25 guidelines for inspection, testing, and maintenance (ITM) is essential for compliance and performance assurance.

9. Choosing the Right Fire Pump Manufacturer

Working with an experienced fire pump manufacturer ensures:

-

Proper system sizing and configuration

-

Customization for your specific industry risks

-

Compliance with relevant standards and certifications

Look for manufacturers who offer:

-

UL/FM certified products

-

Engineering support

-

On-site testing capabilities

-

Global project experience

10. Final Thoughts

Industrial facilities face a unique set of fire safety challenges. By integrating reliable and high-performing fire pumps, these facilities can greatly enhance their fire resilience—protecting both people and assets while ensuring regulatory compliance.

Whether you're designing a new fire protection system or upgrading an existing one, investing in quality fire pumps is a smart decision that delivers peace of mind and long-term value.