Fire pump systems are the heart of many fire protection installations. When a fire breaks out, the fire pump must operate immediately and continuously under extreme conditions. Any failure at that moment can result in catastrophic consequences, including loss of life, severe property damage, and legal liability. This is why redundancy design is a critical topic in modern fire pump system engineering.

Fire pump system redundancy refers to the intentional design approach of eliminating single points of failure by providing backup components, alternative power sources, or parallel systems. In this article, we will explore what redundancy means in fire pump systems, why it matters, how it is applied in real-world projects, and how to design redundancy correctly without unnecessary cost or complexity.

What Is Fire Pump System Redundancy?

Fire pump system redundancy is the practice of ensuring that a fire pump system remains operational even if one component fails. Rather than relying on a single pump, driver, controller, or power source, a redundant system introduces backups that can automatically or manually take over during a fault.

Redundancy does not mean overdesign. Instead, it is a calculated engineering strategy to maintain system reliability under worst-case scenarios, such as power outages, mechanical failures, or maintenance downtime.

In fire protection, redundancy can apply to:

-

Fire pumps

-

Power supplies

-

Pump drivers

-

Controllers

-

Suction and discharge piping arrangements

-

Control and monitoring systems

Why Fire Pump System Redundancy Is Critical

Fire Events Are Non-Negotiable

A fire pump is not a comfort system or a convenience system. It is an emergency system. Unlike HVAC or domestic water systems, a fire pump does not get a second chance to perform. If it fails during a fire, the consequences are immediate and severe.

Single-Point Failures Are a Major Risk

A single-point failure occurs when one component failure disables the entire system. Common examples include:

-

Loss of utility power to an electric fire pump

-

Engine failure in a diesel fire pump

-

Controller malfunction

-

Suction valve failure

Redundancy design aims to eliminate or minimize these risks.

Compliance With Codes and Authority Expectations

While codes such as NFPA 20 do not always mandate full redundancy in every installation, many authorities having jurisdiction, insurance companies, and risk engineers strongly recommend or require redundant fire pump arrangements for:

-

High-rise buildings

-

Data centers

-

Power plants

-

Refineries

-

Large industrial facilities

-

Critical infrastructure projects

Common Types of Fire Pump System Redundancy

Redundant Fire Pumps

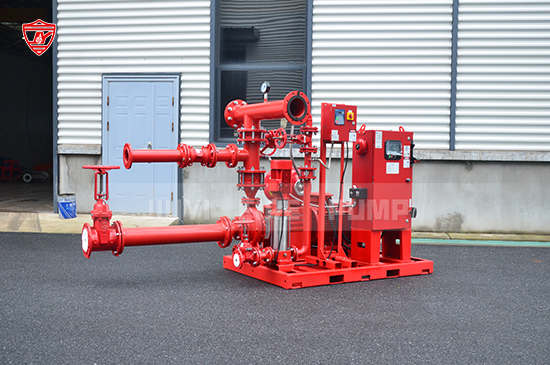

The most common form of redundancy is installing more than one fire pump. This can be achieved in several ways.

One approach is using a primary pump and a standby pump of equal capacity. If the primary pump fails, the standby pump is capable of supplying the full system demand.

Another approach is multiple pumps operating in parallel, where each pump can supply part or all of the required flow depending on system design.

Redundant pumps significantly increase system reliability but require careful hydraulic design to avoid flow imbalance or control conflicts.

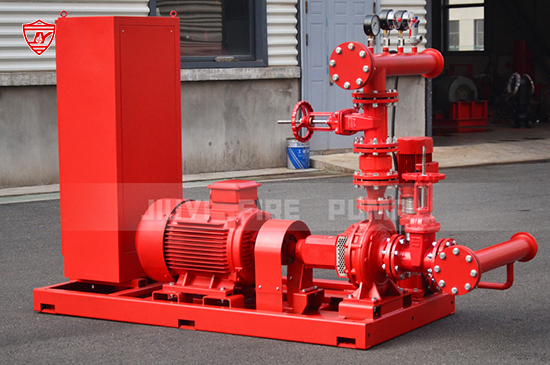

Electric and Diesel Pump Combination

A widely accepted redundancy strategy is combining an electric fire pump with a diesel engine fire pump.

This configuration addresses power reliability concerns. If utility power is lost during a fire, the diesel fire pump remains fully operational. Conversely, if the diesel engine is unavailable due to maintenance or mechanical issues, the electric pump provides primary protection.

This dual-driver approach is commonly used in facilities where uninterrupted fire protection is critical.

Power Supply Redundancy

For electric fire pumps, power supply redundancy can include:

-

Dual utility feeds

-

Dedicated feeders

-

Backup generators

-

Separate routing of power cables

While generators are not considered a replacement for a diesel fire pump in many jurisdictions, they can still enhance overall system resilience when properly designed.

Power supply redundancy reduces the risk of electrical failure disabling the fire pump during emergencies.

Controller Redundancy

Fire pump controllers are the brain of the system. A controller failure can prevent an otherwise healthy pump from starting.

Redundancy strategies may include:

-

Dual controllers for critical pumps

-

Backup control circuits

-

Manual emergency start provisions

High-quality controllers designed for harsh fire conditions are essential to reliable redundancy implementation.

Suction and Water Supply Redundancy

A fire pump is only as reliable as its water supply. Redundancy in water supply can include:

-

Multiple suction sources

-

Dual suction piping

-

Separate underground mains

-

Multiple water storage tanks

If one water source becomes unavailable due to damage, freezing, or maintenance, the alternate source ensures continued fire protection.

Redundancy vs. Reliability: Understanding the Difference

Redundancy is often confused with reliability, but they are not the same.

Reliability refers to the quality and durability of individual components. Redundancy refers to the system-level design that assumes components may fail and prepares for that reality.

A reliable fire pump without redundancy can still fail under unforeseen conditions. A redundant system built with unreliable components is also a risk. The best designs combine high-quality equipment with intelligent redundancy strategies.

How NFPA 20 Influences Redundancy Design

NFPA 20 emphasizes reliability, continuous operation, and proper installation. While it does not universally require redundant fire pumps, it strongly supports redundancy in applications where failure is unacceptable.

NFPA 20 addresses:

-

Separation of power sources

-

Independent drivers

-

Proper arrangement of multiple pumps

-

Reliable controllers and controls

Understanding the intent of NFPA 20 helps designers apply redundancy where it adds real value rather than unnecessary complexity.

When Is Fire Pump Redundancy Necessary?

Not every project requires full redundancy. The level of redundancy should be determined by risk assessment.

Redundancy is strongly recommended for:

-

Facilities with high life-safety risk

-

Buildings where evacuation is difficult

-

Operations with high fire load or hazardous materials

-

Mission-critical facilities where downtime is unacceptable

For smaller or lower-risk buildings, simpler systems may be acceptable if supported by reliable components and proper maintenance.

Common Mistakes in Redundancy Design

Overcomplicating the System

More equipment does not always mean better protection. Excessive redundancy can introduce:

-

Control conflicts

-

Increased maintenance requirements

-

Higher failure probability due to system complexity

Redundancy should be purposeful and well-coordinated.

Ignoring System Integration

Redundant pumps must work as part of a coordinated system. Poor integration can lead to:

-

Pumps fighting each other hydraulically

-

Incorrect starting sequences

-

Delayed response during a fire

System testing and commissioning are critical.

Treating Redundancy as a Cost-Cutting Area

Some projects reduce redundancy to save initial costs. This often results in higher long-term risk, insurance concerns, and potential retrofit expenses later.

A properly designed redundant fire pump system is an investment in safety and operational continuity.

Maintenance Considerations for Redundant Systems

Redundancy does not eliminate the need for maintenance. In fact, redundant systems require disciplined inspection and testing to ensure all backup components remain functional.

Regular testing ensures:

-

Standby pumps remain operational

-

Diesel engines start reliably

-

Controllers switch correctly

-

Valves and sensors function as designed

A redundant system that is not maintained may provide a false sense of security.

Manufacturer’s Role in Redundancy Design

Fire pump manufacturers play a critical role in redundancy success. Properly engineered pump sets, matched components, tested assemblies, and compliant designs significantly reduce system risk.

Manufacturers with experience in redundant fire pump systems can assist with:

-

Proper pump selection

-

Driver and controller compatibility

-

Factory testing strategies

-

Layout and system optimization

Choosing the right manufacturing partner is as important as choosing the right redundancy concept.

Conclusion

Fire pump system redundancy design is not about adding unnecessary equipment. It is about ensuring that when a fire occurs, the system performs without hesitation, regardless of unexpected failures.

By understanding redundancy principles, applying them where risk justifies the investment, and using high-quality fire pump systems, designers and owners can dramatically improve fire protection reliability.

A well-designed redundant fire pump system is not just a technical solution. It is a commitment to safety, resilience, and responsibility.