When it comes to fire protection, compromise is not an option. Whether it's a high-rise building, industrial facility, or data center, fire pump systems play a pivotal role in safeguarding property and lives. While factors like cost, efficiency, and size are often discussed during procurement, reliability is the cornerstone of an effective fire protection strategy. Without it, even the most advanced fire pump system is merely a false sense of security.

This article will explore why reliability is the defining factor in fire pump selection, what contributes to a pump’s reliability, and how you can ensure your fire protection system stands ready when it matters most.

In the fire safety field, reliability refers to the consistent performance and operational readiness of a fire pump over time, especially under emergency conditions. A reliable fire pump is one that:

Starts immediately when triggered

Delivers required water flow and pressure

Operates continuously throughout a fire event

Complies with relevant codes and standards (like NFPA 20 or UL/FM certifications)

Unlike standard industrial pumps, fire pumps are not in regular operation. Their functionality is only tested during inspections or during an actual fire, which is why failure is unacceptable.

Fire pump systems are a building’s last line of defense. A single failure to start or deliver required water pressure can result in:

Delayed suppression of fire

Rapid escalation of fire damage

Fatalities or serious injury

Complete structural loss

NFPA 20 requires that fire pumps be selected, installed, and maintained to ensure "maximum reliability." Many insurance companies will only approve claims if the fire pump system was compliant and operational at the time of the incident.

Fires grow exponentially. A delay of even 60 seconds in water delivery can mean the difference between controlling a fire and watching it spread beyond recovery.

Facilities like hospitals, data centers, power plants, and oil refineries cannot afford a fire pump failure. Reliability becomes the single most critical selection criterion for such projects.

Choosing a reliable fire pump involves more than just selecting a reputable brand. Here are the key factors that impact system reliability:

UL Listed and FM Approved pumps are rigorously tested for reliability under extreme conditions.

NFPA 20 compliance ensures that the pump system adheres to global fire safety benchmarks.

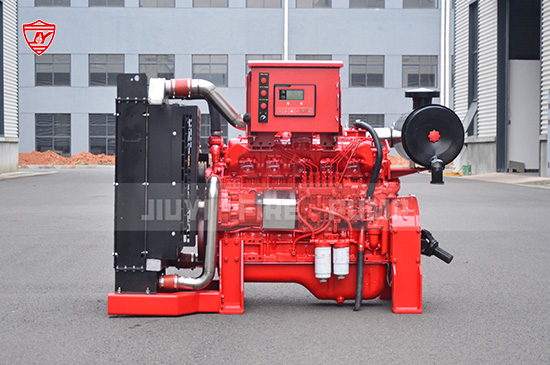

Diesel Fire Pumps: Reliable in areas with unstable electricity supply but require more maintenance and regular testing.

Electric Fire Pumps: Lower maintenance and high reliability if power supply is stable and backed by emergency generators.

Jockey Pumps: Not fire pumps themselves, but they maintain system pressure and reduce main pump wear, indirectly supporting reliability.

Corrosion-resistant materials like bronze impellers or ductile iron casings improve longevity. Poor-quality materials can result in seal failure, motor burnout, or pressure inconsistencies over time.

An under- or over-sized pump can lead to:

Cavitation

Overheating

Inadequate pressure delivery

Frequent cycling—all affecting long-term reliability

Even the most robust fire pump requires regular testing. NFPA 25 mandates weekly or monthly pump tests depending on your system type. Neglecting this can render even the most advanced system unreliable.

When choosing a fire pump, the manufacturer plays a major role in the system's reliability. Here’s what to look for:

Choose manufacturers with installations in critical facilities like airports, government buildings, or oil refineries.

Manufacturers that provide pre-assembled, skid-mounted pump sets with controllers and piping reduce installation risks and improve reliability.

Reliable systems require reliable support. Ensure the supplier provides:

Startup commissioning

Troubleshooting assistance

Spare parts availability

Long-term maintenance services

Only select suppliers that conduct factory acceptance tests (FAT) on all units before shipping.

To ensure your fire pump system is dependable, follow these best practices: