In fire protection systems, reliability is not optional—it is a lifesaving necessity. One of the most critical components ensuring this reliability is the fire pump system, which delivers adequate water pressure and flow during a fire emergency. But what happens if the main fire pump fails? That’s where a redundant fire pump setup becomes crucial.

This article will walk you through what a redundant fire pump system is, why it’s important, when it’s required, and how it ensures compliance with international standards like NFPA 20. Whether you’re an engineer, contractor, facility manager, or fire safety professional, understanding redundancy in fire pump systems is key to designing and maintaining effective fire protection infrastructure.

A redundant fire pump setup refers to a fire protection system that includes two or more fire pumps, so if one pump fails, the other can immediately take over without interrupting the water supply to the fire sprinkler or standpipe systems.

This setup ensures uninterrupted protection and provides peace of mind in critical environments such as high-rise buildings, hospitals, data centers, airports, manufacturing plants, and petrochemical facilities—anywhere the consequences of failure are catastrophic.

During a fire emergency, water must be delivered continuously and at the correct pressure. A single point of failure in a system can result in delayed or insufficient firefighting capacity, risking lives and assets.

Some buildings and projects—especially those classified as high hazard—are required by NFPA 20, insurance providers, or local authorities to include redundancy in fire pump design.

Like all mechanical equipment, fire pumps can fail due to electrical faults, wear and tear, or unforeseen malfunctions. A redundant system mitigates this risk by having a second pump immediately available.

Two electrically driven pumps operate in a primary/standby configuration. The second pump activates if the first one fails or cannot meet demand.

Best for: Locations with highly reliable power supply.

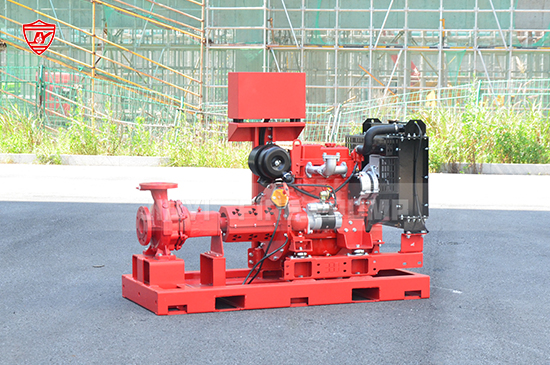

This is one of the most popular redundant configurations. It combines an electric fire pump with a diesel-driven pump, ensuring the system can function even during a power outage.

Best for: Facilities requiring backup power independence.

Used where electric power is unreliable or unavailable. Two diesel pumps operate in primary/backup mode.

Best for: Remote areas or industrial zones with no stable electricity.

Some mission-critical facilities install three fire pumps for extra assurance—often two active pumps and one standby.

Best for: Nuclear plants, major airports, or defense-related infrastructure.

NFPA 20 (Standard for the Installation of Stationary Pumps for Fire Protection) outlines the design, installation, and performance criteria for fire pumps. While it doesn’t mandate redundancy in all cases, it emphasizes that where redundancy is required by other codes or owners, the redundant system must meet the same performance requirements as the primary pump.

Key NFPA 20 requirements include:

Pumps must be independently operable.

Must have independent power sources.

Must be sized to meet 100% system demand individually.

NFPA 20 also allows parallel pump installations where each pump can handle the full system demand.

To ensure true redundancy, it’s not just the pumps that must be duplicated. A well-designed redundant fire pump system may include:

Independent pump controllers

Separate suction and discharge piping

Independent power sources (electric grid + generator/diesel)

Check valves and isolation valves

Alarm and monitoring systems for each pump

Jockey pumps to maintain pressure and reduce unnecessary starts

Redundant systems are not mandatory for all buildings, but they are considered best practice—or a requirement—under several circumstances:

| Application | Redundancy Required? |

|---|---|

| High-rise buildings | Often recommended |

| Data centers | Yes |

| Airports | Yes |

| Hospitals | Yes |

| Petrochemical plants | Yes |

| Warehouses | Sometimes |

| Schools | Optional |

A redundant fire pump setup can increase the initial cost by 30–70%, depending on configuration. However, consider the lifetime cost of a fire in a high-value building due to pump failure: millions in damage, potential fatalities, and legal liabilities.

A well-designed redundant system is a strategic investment that protects not only infrastructure but also lives and reputation.

Maintaining redundancy isn’t just about installing two pumps—it requires ongoing care. According to NFPA 25 (Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems), fire pumps must be:

Tested weekly (churn test)

Flow-tested annually

Inspected visually for leaks, corrosion, and vibration

Monitored through alarm panels and controllers

Redundant systems may require separate maintenance schedules, and logs must be kept for each pump.

You may need to consider a redundant system if:

Your facility is mission-critical or high-risk.

Local fire codes or insurers require it.

You have a large or complex fire protection system.

Your pump is the only source of fire protection water.

Failure would cause unacceptable consequences.

Work with a UL-listed, NFPA-compliant fire pump manufacturer to determine:

Required flow and pressure (gpm and psi/bar)

Suitable power source combinations

Installation location (indoor/outdoor)

Diesel engine or electric motor sizing

Controller and monitoring preferences

Certification requirements (UL, FM, LPCB)

In the fire safety industry, there is no room for failure. A redundant fire pump setup is more than an upgrade—it’s a smart safeguard for critical infrastructure. Whether you’re retrofitting an old building or designing a new facility, investing in fire pump redundancy ensures that your system will perform when it matters most.

At Better Technology Group, we specialize in UL Listed and NFPA 20 compliant fire pump packages, including redundant systems with electric, diesel, or hybrid configurations. Contact us today to discuss how we can support your fire protection needs with dependable pump solutions that never compromise on safety.