In any fire protection system, the fire pump serves as the heart of the entire network, ensuring adequate water pressure and flow in the event of a fire emergency. These systems are often the last line of defense between a small fire and a catastrophic loss of life or property. However, even the most reliable fire pump can fail if not properly maintained and regularly tested.

This is why weekly fire pump testing, as mandated by NFPA 25, is a critical routine. It ensures that the fire pump is operational, functional, and ready to perform when needed most. In this article, we explain the importance of weekly fire pump testing, industry regulations, what a weekly test involves, and the risks of skipping this vital task.

The Role of a Fire Pump in a Fire Protection System

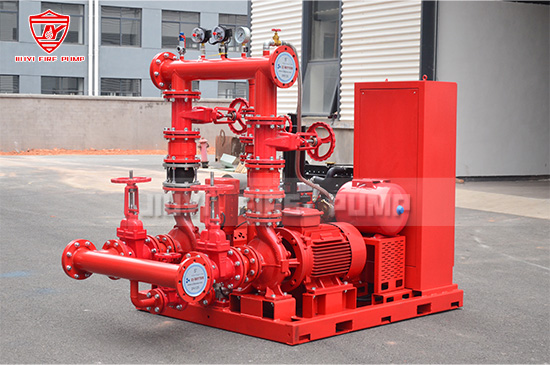

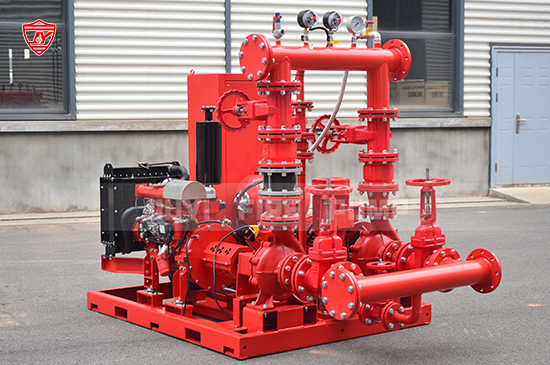

A fire pump is a vital component of a building’s fire protection system. When the water supply (from a tank, reservoir, or municipal line) cannot provide adequate pressure for the fire protection system, a fire pump boosts that pressure to meet the requirements of sprinklers and standpipes.

Fire pumps are typically installed in high-rise buildings, warehouses, industrial plants, hospitals, airports, and other large facilities where water pressure requirements are demanding. They must operate immediately and flawlessly during emergencies—and that’s where routine testing comes into play.

NFPA 25 and Weekly Fire Pump Testing

NFPA 25: Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems is the primary document governing fire pump testing. According to NFPA 25, weekly testing is required for diesel-driven fire pumps and recommended for electric fire pumps unless they are under a fire risk management plan that allows for monthly testing.

The weekly test is designed to:

-

Ensure the fire pump starts and runs correctly

-

Detect early signs of wear, damage, or system failure

-

Confirm there are no leaks or obstructions

-

Guarantee that the automatic starting system is functioning

Failing to comply with these testing requirements can result in fines, insurance issues, and worse—failure of the system during a fire.

Why Is Weekly Fire Pump Testing So Important?

1. Reliability During Emergencies

A fire pump may sit idle for weeks or even months. Without weekly testing, there’s no guarantee it will start properly when needed. Weekly operation keeps the system “exercised” and prevents critical components from seizing, corroding, or deteriorating.

2. Early Detection of Mechanical Issues

Routine testing allows maintenance teams to identify issues such as:

-

Air in suction lines

-

Fuel system leaks (for diesel pumps)

-

Improper pressure readings

-

Electrical faults (for electric pumps)

Addressing small issues during weekly inspections can prevent complete pump failure during an emergency.

3. Compliance with NFPA and Local Codes

Building owners are legally responsible for maintaining their fire protection systems. Failure to comply with NFPA 25 can result in citations from the fire marshal, revoked occupancy permits, or liability in the event of a fire-related incident.

4. Insurance Requirements

Many insurance providers require documented proof of regular testing and maintenance of fire safety systems. Skipping weekly tests can void insurance coverage or result in higher premiums.

5. Operational Readiness of Backup Power Sources

Diesel-driven fire pumps rely on batteries and fuel systems, which can degrade or deplete over time. Weekly tests ensure that backup systems are in working order and ready to go during power outages.

What Does a Weekly Fire Pump Test Involve?

A standard weekly fire pump test (also called a churn test) includes the following steps:

1. Visual Inspection

-

Check for leaks, wear, or damage

-

Confirm that pump room temperature is adequate

-

Inspect fuel levels and battery condition (diesel pumps)

2. Manual or Automatic Start

-

The pump should start automatically via pressure drop or be started manually for testing

-

Monitor the time it takes for the pump to start

3. No-Flow (Churn) Test

-

Run the pump with discharge valves closed (no-flow condition)

-

Monitor pressure gauge readings

-

Listen for unusual noises or vibrations

4. Record Readings

-

Suction pressure

-

Discharge pressure

-

Pump RPM (if applicable)

-

Ampere draw for electric pumps

-

Battery voltage for diesel pumps

5. Stop and Inspect

-

Shut down the pump

-

Inspect again for leaks or changes in system conditions

-

Reconfirm readiness

This test should be documented carefully, with any abnormalities noted and corrected immediately.

Diesel Fire Pumps vs. Electric Fire Pumps: Why Testing Frequency May Differ

Diesel Engine Fire Pumps

Diesel pumps have more mechanical and fuel system components that can fail or degrade faster than electric pumps. As such, NFPA 25 mandates weekly testing for diesel pumps. This helps ensure that the:

-

Batteries are charged

-

Fuel is not contaminated

-

Engine starts promptly

Electric Motor Fire Pumps

Electric pumps are generally more stable but are still subject to issues like:

-

Faulty controllers

-

Power supply issues

-

Motor winding problems

Weekly testing is strongly encouraged, though monthly testing is permissible under specific risk management programs. Still, many safety-conscious facilities choose to test electric pumps weekly for extra assurance.

Consequences of Neglecting Weekly Testing

-

Delayed Pump Activation: A pump that fails to start immediately during a fire can cost lives and property.

-

Increased Repair Costs: Small problems, when undetected, turn into expensive repairs.

-

Legal and Regulatory Penalties: Fines or operational shutdowns from fire inspectors.

-

Insurance Liability: Denied claims in the event of a fire due to lack of testing.

-

Loss of Life or Property: The most serious risk—system failure when it's needed the most.

How to Automate and Simplify Weekly Testing

For busy facilities, conducting weekly tests can seem like a burden. However, automation and outsourcing can simplify this task:

-

Use Fire Pump Controllers with Auto Test Features: These can be programmed to simulate pressure drops and run tests at set intervals.

-

Install Remote Monitoring Systems: Monitor pump health, fuel levels, and electrical data remotely with alarms for abnormal conditions.

-

Hire Professional Maintenance Services: Certified technicians can perform and document all tests, ensuring compliance and peace of mind.

Best Practices for Fire Pump Maintenance

-

Keep a Detailed Logbook: Document every weekly test, including date, time, readings, and any issues found.

-

Train Your Staff: Ensure that personnel know how to perform the test safely and accurately.

-

Schedule Preventive Maintenance: In addition to testing, schedule regular full inspections, flow tests, and part replacements.

-

Keep the Pump Room Clean and Accessible: Clutter or poor environmental conditions can affect system performance.

Conclusion

Your fire pump is the silent guardian of your building’s fire protection system. It may sit unused for years, but when it’s needed, it must work flawlessly. That’s why weekly fire pump testing is not just a regulatory checkbox—it’s a life-saving responsibility.

Whether you have a diesel or electric fire pump, consistent testing ensures performance, extends equipment lifespan, and guarantees your system is ready for any emergency. Stay compliant, stay protected, and most importantly—stay fire-ready.