Fire pump systems are the backbone of any active fire protection system. When a fire occurs, there is no second chance for failure. Unlike many mechanical systems that allow downtime, a fire pump must perform immediately and reliably under the most extreme conditions. This is why fire pump system redundancy is not optional in many applications—it is a fundamental requirement for safety, compliance, and risk control.

Fire pump system redundancy refers to the design practice of providing backup pumping capacity to ensure that the fire protection water supply remains available even if one component fails. In modern fire safety engineering, redundancy is a critical design philosophy that aims to eliminate single points of failure.

This article explains why fire pump system redundancy is required, how it improves system reliability, and why it is strongly emphasized by fire codes, insurers, and authorities having jurisdiction.

Fire pumps are responsible for delivering sufficient water flow and pressure to fire suppression systems such as sprinklers, standpipes, monitors, and hydrants. In many facilities, especially high-rise buildings, industrial plants, warehouses, data centers, and power facilities, municipal water pressure alone is insufficient.

A fire pump must:

Start automatically

Deliver rated flow and pressure

Operate continuously for extended durations

Function during power outages or emergency conditions

If a fire pump fails during a fire event, the entire fire protection system may become ineffective. This risk is unacceptable in life safety systems, which is why redundancy is built into professional fire pump system design.

Fire pump system redundancy means designing the system so that failure of a single pump, driver, controller, or power source does not disable fire protection.

Redundancy can be achieved through:

Multiple fire pumps

Different pump drivers

Independent power supplies

Separate controllers and control circuits

Parallel or standby pump arrangements

The goal is simple: ensure that water is always available when needed, regardless of mechanical, electrical, or operational failures.

A single-point failure is any component whose failure causes the entire system to stop functioning. Fire protection standards aim to eliminate these weak points.

Examples of single-point failures include:

One electric fire pump with no backup power

One diesel fire pump with no standby unit

A single controller serving multiple pumps

Shared suction or discharge piping without isolation capability

Fire pump redundancy ensures that if one pump fails to start, loses power, or requires maintenance, another pump can immediately take over without compromising system performance.

Fire pump system redundancy is not just a best practice; it is often a code-driven requirement.

Major fire protection standards emphasize redundancy, including:

NFPA 20 requirements for reliable fire pump installations

Building codes for high-rise and critical infrastructure

Insurance and loss prevention guidelines

Local authority requirements for mission-critical facilities

While codes may not mandate redundancy for every project, they strongly require it in:

High-rise buildings

Large-area sprinkler systems

Industrial and petrochemical facilities

Airports, hospitals, and data centers

Facilities with high fire risk or high occupant load

Authorities having jurisdiction often require redundant fire pumps when the consequences of system failure are severe.

One of the most common reasons for fire pump redundancy is power supply reliability.

Electric fire pumps depend on utility power or emergency generators. However, fires frequently cause power outages due to:

Damaged electrical infrastructure

Tripped breakers

Fire-damaged substations

Utility shutdowns during emergencies

To mitigate this risk, redundant designs may include:

An electric fire pump combined with a diesel fire pump

Multiple electric pumps fed by independent power sources

Diesel fire pumps with separate fuel systems

Using different types of drivers significantly improves system reliability by reducing dependency on a single energy source.

No mechanical system is immune to failure. Fire pumps, like all rotating equipment, are subject to:

Bearing wear

Seal failure

Coupling misalignment

Lubrication issues

Overheating

Even with proper maintenance, unexpected mechanical failure can occur. Fire pump redundancy ensures that mechanical issues do not leave a facility unprotected during a fire event.

A standby fire pump can automatically start if the primary pump fails to meet pressure demand, ensuring continuous operation.

Fire pump systems require regular testing, inspection, and maintenance to remain compliant and reliable.

Without redundancy:

Maintenance requires system shutdown

Fire protection coverage is temporarily compromised

Permits or fire watches may be required

With redundant fire pumps:

One pump can remain in service while another is maintained

Fire protection remains fully operational

Facility downtime and operational risk are reduced

This is particularly important for facilities that operate continuously and cannot tolerate fire protection interruptions.

System availability refers to the probability that a system will operate successfully when required.

Fire pump redundancy dramatically increases availability by:

Providing backup capacity

Reducing downtime risk

Allowing automatic failover

Enhancing reliability during emergencies

High-availability fire protection systems are essential in environments where fire consequences include loss of life, major economic damage, or environmental impact.

In some applications, redundancy is not only about failure protection but also about meeting variable demand.

Examples include:

Large sprinkler zones activating simultaneously

Firefighting hose streams operating alongside sprinklers

Expansion of facility hazard classification over time

Multiple fire pumps operating in parallel can:

Share flow demand

Maintain stable pressure

Adapt to changing system requirements

Redundant designs offer flexibility for future system expansion without complete replacement.

Insurance providers and risk engineers often require fire pump system redundancy as a condition for coverage or reduced premiums.

From a risk management perspective:

Redundancy reduces loss probability

Improves fire response reliability

Demonstrates commitment to safety

Lowers long-term risk exposure

Facilities with redundant fire protection systems are viewed as lower risk and better prepared for emergency scenarios.

Certain facilities have zero tolerance for fire protection failure.

These include:

Data centers

Power generation plants

Oil and gas facilities

Chemical manufacturing plants

Airports and transportation hubs

Hospitals and healthcare facilities

In such environments, fire pump redundancy is not optional—it is essential. Failure could result in catastrophic operational, financial, or life safety consequences.

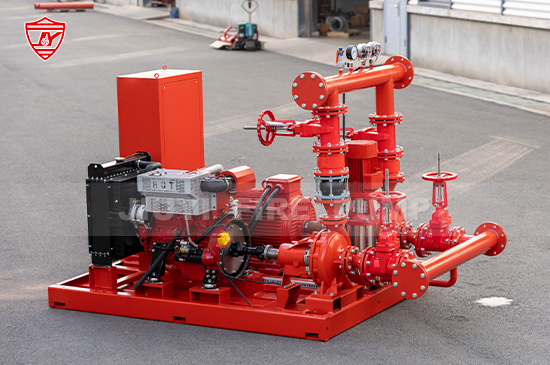

Typical redundant fire pump arrangements include:

One duty pump and one standby pump

Electric pump with diesel pump backup

Multiple pumps operating in parallel

Separate controllers and power feeds

Independent suction and discharge isolation valves

The specific configuration depends on:

System demand

Code requirements

Facility risk profile

Authority approval

Engineering design strategy

A well-designed redundant fire pump system balances reliability, cost, and compliance.

As a fire pump manufacturer, understanding redundancy requirements is critical. Equipment must be designed to:

Operate reliably under emergency conditions

Integrate seamlessly into redundant systems

Meet applicable fire standards

Support long-term maintenance and testing

Manufacturers play a key role in supporting engineers and contractors by providing:

Reliable fire pump packages

Compatible controllers and drivers

Flexible configurations for redundancy

Proven performance and compliance

Fire pump system redundancy is required because fire protection systems cannot afford to fail. Redundancy eliminates single-point failures, improves reliability, ensures compliance with fire codes, and protects lives and assets.

Whether driven by code, insurance, risk management, or operational necessity, redundant fire pump systems provide the confidence that water will be available when it matters most. In fire safety engineering, redundancy is not excess—it is essential protection against the unexpected.

For facilities where safety, compliance, and reliability are non-negotiable, fire pump system redundancy is a fundamental design requirement, not an optional upgrade.