In any fire protection system, the fire pump is the heart that drives the entire operation. When it stops working, the consequences can be catastrophic, especially during a fire emergency. Whether your system relies on electric, diesel, or vertical turbine fire pumps, quick response and systematic troubleshooting are essential.

As a professional fire pump manufacturer, we’ve prepared this guide to help facility managers, fire protection contractors, and system operators understand what to do when a fire pump fails.

When a fire pump stops working, immediate panic may lead to unnecessary damage or missteps. The first step is to determine:

Is the failure during a fire emergency or during routine testing?

Did the pump stop suddenly or fail to start at all?

Is this a recurring issue or the first occurrence?

Your answers help define the urgency and direction of your response.

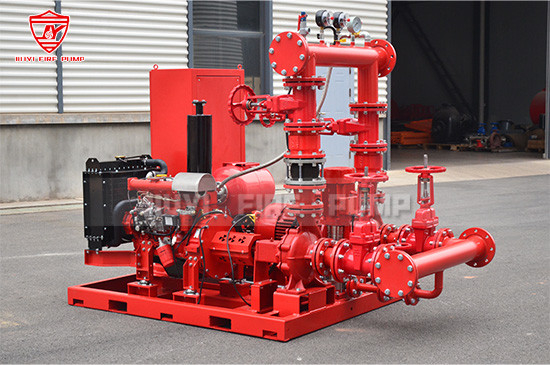

Each type of fire pump—electric motor-driven, diesel engine-driven, or steam turbine—has different failure modes.

Electric Fire Pumps: Often fail due to power supply interruptions, controller faults, or motor issues.

Diesel Engine Fire Pumps: Common failures include battery issues, fuel problems, or engine control faults.

Vertical Turbine Fire Pumps: May stop due to shaft misalignment, bearing failure, or suction line obstructions.

Knowing your pump type enables faster diagnosis and safe inspection procedures.

The fire pump controller is the “brain” of the system. It starts and stops the pump and records data. When the pump fails:

Inspect the control panel display or indicators for error codes.

Look for alarms such as phase failure, undervoltage, or start failure.

Confirm if the manual start function works.

If the controller is unresponsive, test for power supply issues or inspect the backup power source.

For electric pumps, check:

Incoming power voltage and phase balance.

Circuit breakers or fused disconnects.

Ground faults or signs of overheating in the wiring or motor.

For diesel pumps, inspect:

Battery voltage and terminal connections.

Battery charger operation.

Starter solenoid and control wiring.

Even new systems may suffer from loose connections or power disturbances.

If the power supply is normal, move on to mechanical components.

Pump Coupling: Inspect the flexible coupling or drive shaft for damage or misalignment.

Bearings: Listen for unusual noises. Overheating or friction could indicate bearing wear.

Suction/Discharge Valves: Ensure valves are fully open. Closed discharge valves may cause overheating and premature shutdown.

Impeller: If accessible, check for blockages caused by debris or corrosion.

For diesel fire pumps, check:

Fuel levels and filter clogs

Oil pressure

Cooling system integrity

Use OEM checklists where available and follow NFPA 20 recommendations.

An often-overlooked but essential tool is the test logbook.

Compare the most recent operational test with historical data.

Check for declining pressure, reduced flow, or longer startup times.

Spot patterns that suggest progressive failure, such as declining RPMs or pressure buildup delays.

Fire pump logs can reveal critical insights that prevent future failures.

Fire pump systems are life safety equipment. In case of failure:

Contact a licensed fire protection technician or the pump manufacturer’s support team.

Do not attempt major repairs unless you are certified and authorized.

Isolate the fire pump area if necessary and post warning signage.

If available, switch to a backup pump or jockey pump if allowed by system design.

Better Pump offers remote support and diagnostic services for certified installers and facility teams.

Sometimes, a fire pump won’t start because the jockey pump is running continuously, masking small leaks or false pressure drops.

Check:

If the jockey pump pressure settings are correct

For system leaks, valve issues, or bladder tank damage

Whether the fire pump start pressure is calibrated properly

This is a common issue in high-rise or complex piping systems.

Preventive maintenance is your best defense against fire pump failure. NFPA 25 requires:

Weekly: Pump test run (minimum 10 minutes diesel / 30 minutes electric)

Monthly: Pump controller inspection and record review

Quarterly: Relief valve, sensing lines, and alarm device checks

Annually: Flow test, full controller test, vibration check, and suction piping inspection

Engaging your fire pump manufacturer for scheduled inspections and part replacements helps extend system life.

All facilities should have a written emergency plan specific to fire pump failure:

Assign response roles (electrical, mechanical, safety)

Maintain 24/7 access to OEM support contacts

Keep spare parts like fuses, relays, batteries, and lubricants on-site

Label all valves, switches, and isolation points clearly

This will reduce downtime and ensure legal compliance with fire safety codes.

When a fire pump stops working, immediate, informed action is essential. By understanding the type of pump, checking the controller, inspecting the mechanical components, and following NFPA standards, you can restore function quickly and safely.

Regular testing, system monitoring, and collaboration with your fire pump manufacturer are key to preventing future issues. We support clients worldwide with high-performance fire pumps, OEM technical support, and comprehensive maintenance services.