Fire pumps play a critical role in building fire protection systems. These pumps are designed to boost water pressure to fire sprinkler systems and standpipes when the existing water supply is inadequate. But just as important as selecting the right fire pump is determining where the pump should be located. Proper placement ensures both operational reliability and code compliance—two essentials in any fire protection strategy.

This article explores the most common fire pump locations, the factors that influence their placement, and relevant standards such as NFPA 20 and local codes. Whether you are an engineer, contractor, facility manager, or building owner, understanding fire pump location considerations will help you design safer, more efficient systems.

The location of a fire pump can significantly affect the following:

Pump performance and reliability

Ease of maintenance and inspection

Response time in an emergency

Compliance with fire safety regulations

Protection from environmental hazards

Improper placement may lead to reduced water pressure, delayed fire response, damage to equipment, or failure to meet regulatory codes—all of which can endanger lives and property.

What it is:

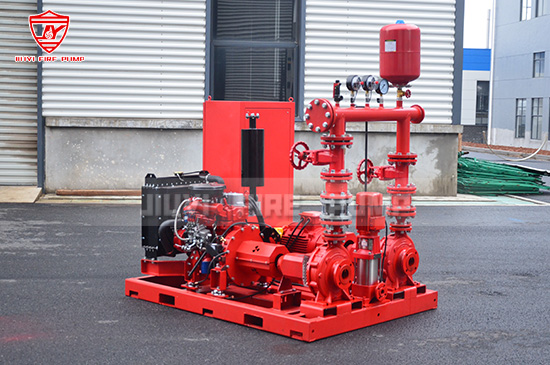

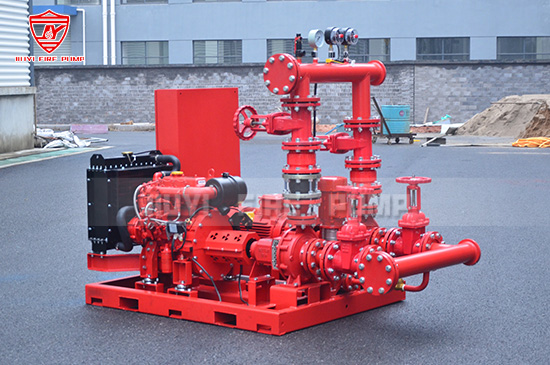

A fire-rated, enclosed space designed specifically to house fire protection equipment such as the fire pump, controller, jockey pump, and associated valves and fittings.

Why it’s used:

This is the most preferred and code-compliant location because it offers physical protection, access control, and space for maintenance.

Typical features:

2-hour fire-rated walls (per NFPA 20)

Clear access to pump and controller

Proper ventilation and drainage

Flood protection measures

Adequate lighting and clearance

Positioned at or below the water supply source (e.g., ground level or basement)

Best for:

Large commercial buildings, hospitals, high-rises, and industrial facilities.

Why it’s chosen:

Basements often provide easier access to a water source like a municipal main or underground water tank. Fire pumps at this level are typically "flooded suction," meaning water flows into the pump by gravity, ensuring optimal priming conditions.

Considerations:

Must be protected against flooding

Requires safe and dry access for maintenance personnel

Adequate drainage and sump pumps should be installed

May require ventilation systems

Best for:

Buildings with basement-level utility spaces or underground water tanks.

Why it’s chosen:

Locating the fire pump room close to the building’s main water entry allows for straightforward pipe layout and pressure optimization.

Considerations:

Should still be in a separate, fire-rated enclosure

Must meet clearance and access standards

May be preferable when basement space is not available

Best for:

Warehouses, low-rise commercial buildings, and schools.

Why it’s chosen:

Sometimes building designers consider placing fire pumps in shared mechanical spaces to save room or reduce construction costs.

Risks & Restrictions:

Not ideal due to interference with other utilities

Can pose risks if equipment creates excessive heat or moisture

May violate NFPA 20 if space is not fully dedicated to fire protection

Best for:

Small buildings only if full separation and code compliance can be achieved.

Why it’s chosen:

For remote buildings or facilities with limited indoor space, fire pumps may be placed in weatherproof outdoor enclosures.

Design considerations:

Must be freeze-protected in cold climates

Should include fire-rated construction or barriers

Requires robust security and weather resistance

Easy vehicle access for diesel pump refueling

Best for:

Industrial plants, power stations, remote warehouses, or large campuses.

Why it’s rare:

Pumps located above their water source can suffer from priming issues, requiring suction lift pumps, which are generally discouraged for fire protection.

Limitations:

Complicated maintenance and access

NFPA 20 advises against installations where the pump is above the suction source

Best for:

Certain retrofit projects or systems with rooftop water tanks (e.g., in high-rise buildings in specific regions like Asia).

According to NFPA 20 and other international standards, fire pump locations must meet several key requirements:

Must be easily accessible from the building exterior or common areas

Dedicated access doors and emergency lighting required

2-hour fire-rated enclosures

If located in a flood-prone area, the room should be raised or have proper drainage

Minimum clearance around the pump (typically 3 ft or 1 meter)

Enough space for maintenance and replacement

Adequate air flow, especially for diesel engine fire pumps, which need intake and exhaust systems

The pump room should be locked but accessible to fire protection personnel

Unauthorized access should be restricted

The fire pump's suction side—the pipe delivering water into the pump—must be carefully designed and aligned with pump location. Ideally:

Use flooded suction (gravity-fed) arrangements

Avoid suction lift where the pump pulls water from below its level

Short, straight suction pipes with minimal elbows are best

Several international standards offer guidelines for fire pump placement:

NFPA 20 – Standard for the Installation of Stationary Pumps for Fire Protection

Specifies fire pump room design, access, protection, and layout.

International Building Code (IBC)

May require fire separation and occupancy-specific provisions.

Local Fire Department Requirements

Some regions have additional location requirements or need AHJ (Authority Having Jurisdiction) approval.

Sharing space with other utilities

Mixing fire pumps with HVAC or electrical equipment often leads to compliance issues.

Placing the pump above the water supply source

Can cause priming failure and affect reliability.

Neglecting drainage in basements

Flooded pump rooms are a leading cause of system failures.

Ignoring local fire codes

Even if NFPA 20 is followed, local regulations may differ.

Correctly locating a fire pump is not just about available space—it’s a matter of life safety, code compliance, and long-term reliability. Whether you’re designing a new fire protection system or retrofitting an old one, prioritizing a dedicated, protected, and accessible space for your fire pump will ensure it functions when you need it most.

As a trusted fire pump manufacturer, we recommend consulting with professionals who understand both your building layout and applicable codes. Our team at Better Technology Group is always here to support your fire protection projects with technical advice, code-compliant products, and expert service.