A properly designed fire pump foundation is critical for ensuring the stability, performance, and longevity of fire pump systems. While fire pumps themselves are the heart of a fire protection system, the foundation serves as the backbone — providing the necessary structural support and minimizing vibrations during operation. A poorly designed or installed foundation can lead to misalignment, excessive vibration, and even premature pump failure.

This article will explore the fundamental principles and recognized standards for fire pump foundation design, focusing on NFPA 20 and other relevant engineering guidelines.

A fire pump foundation is more than just a concrete block under the pump. It plays multiple roles in system reliability and safety:

Structural Support: The foundation carries the total weight of the fire pump, driver, baseplate, and other accessories, maintaining alignment throughout operation.

Vibration Control: A well-designed foundation absorbs vibration and prevents it from being transmitted to the surrounding structure.

Alignment Stability: The baseplate and foundation combination keeps the pump and driver in precise alignment, preventing mechanical stress and wear.

Longevity: A strong, stable foundation reduces maintenance frequency and extends equipment life.

Without a proper foundation, even a UL-listed or NFPA 20–compliant pump cannot perform as intended.

The most widely recognized design standard is NFPA 20 – Standard for the Installation of Stationary Pumps for Fire Protection. NFPA 20 provides the essential requirements for pump installation, including foundation and alignment recommendations.

Other references used by engineers and installers include:

Hydraulic Institute Standards – covering pump installation and vibration limits.

AISC (American Institute of Steel Construction) – for baseplate and anchor bolt design.

ACI (American Concrete Institute) – for foundation concrete design and curing.

Manufacturer Guidelines – specific requirements based on pump size, type, and driver configuration.

Together, these standards ensure that the foundation design is structurally sound, vibration-free, and aligned with fire protection system performance requirements.

NFPA 20 outlines several important points regarding foundation design and installation.

The foundation must be strong enough to support the total static and dynamic load of the fire pump and driver. It should also resist vibration and maintain alignment under all conditions. Typically, the foundation should weigh at least three times the total weight of the pump and motor combined.

The recommended mass of the foundation ensures proper vibration damping. A heavier foundation helps absorb mechanical vibrations, which reduces stress on the coupling and bearings.

NFPA 20 recommends that concrete foundations be allowed to cure fully before grouting and installing the pump set. Usually, a minimum curing period of 7–10 days is advised, depending on the mix and site conditions.

After the pump and driver are aligned, the baseplate should be grouted with a non-shrink grout to provide uniform support and maintain alignment. The grout prevents deflection and dampens vibration.

Anchor bolts should be accurately located and embedded in the concrete foundation. After installation, pump and motor alignment must be rechecked and corrected if necessary. NFPA 20 requires that alignment be verified after grouting and again after system operation.

While NFPA 20 provides the general requirements, practical engineering experience offers several design practices to ensure a reliable installation.

Concrete Grade: Typically, a minimum compressive strength of 3,000 psi (21 MPa) is recommended.

Reinforcement: Use rebar reinforcement per ACI standards to prevent cracking under load.

Vibration Isolation: For installations near sensitive equipment, vibration pads or isolation mounts may be used.

The foundation should extend at least 6 inches (150 mm) beyond the baseplate on all sides.

The top surface must be level and smooth to ensure even support.

The foundation depth should be sufficient to prevent settlement and maintain stiffness.

Use high-strength, non-shrink grout to fill the space between the baseplate and foundation.

Ensure full contact under the baseplate to prevent deflection.

Allow the grout to cure completely before tightening bolts or connecting piping.

Anchor bolts should be positioned accurately according to the manufacturer’s baseplate drawing. It is recommended to use sleeves or templates during concrete casting to allow for minor adjustments during installation.

Fire pump systems experience vibration due to rotating parts, unbalanced loads, or coupling misalignment. Over time, vibration can cause mechanical damage or piping stress. Proper foundation design minimizes these risks.

After the pump and driver are mounted, alignment should be checked using precision tools. Alignment must be verified:

Before grouting,

After grouting, and

After final pipe connections.

Misalignment of the coupling between pump and motor is one of the most common issues. The allowable misalignment tolerance should follow manufacturer recommendations, typically within 0.002 to 0.004 inches.

For critical installations, vibration measurements should be taken after startup. Vibration limits can refer to Hydraulic Institute Standard ANSI/HI 9.6.4, which defines acceptable levels for pumps based on speed and size.

Even experienced contractors sometimes overlook critical details in fire pump foundation work. Below are frequent errors to avoid:

Inadequate curing time before installation, causing uneven settlement.

Improper leveling of the baseplate, leading to misalignment.

Insufficient grout coverage, resulting in voids under the baseplate.

Incorrect anchor bolt positioning, preventing proper mounting.

Neglecting re-alignment after connecting suction and discharge piping.

Addressing these points during installation helps avoid costly maintenance later and ensures system reliability.

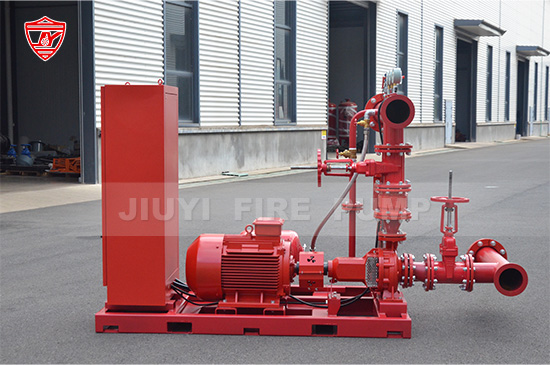

A typical concrete foundation for an end suction or split case fire pump includes the following elements:

Reinforced concrete block with anchor bolts cast in place.

Pump and driver mounted on a steel baseplate.

Precision leveling shims under the baseplate.

Non-shrink grout filling all voids.

Anchor bolts tightened after grout curing.

Alignment rechecked after piping connection.

This setup ensures the fire pump operates within its design limits and maintains efficiency for years of service.

Different fire pump configurations require slightly different foundation considerations.

Usually compact, they require a smaller foundation but must maintain precise alignment between motor and pump.

Heavier units requiring larger foundations with sufficient mass to counter dynamic loads.

Typically installed over a wet well or tank, they require a foundation that supports the discharge head and transmits the load to the supporting structure below.

Require additional consideration for vibration and exhaust system forces. The foundation must be strong enough to handle engine torque and vibration without movement.

Even after installation, foundation integrity should be periodically inspected. Regular checks include:

Cracks or settlement in the concrete base.

Loosened anchor bolts.

Grout deterioration or voids.

Changes in alignment or vibration levels.

Any deviation should be addressed immediately to prevent pump performance issues. Preventive maintenance ensures system readiness and compliance with fire protection standards.

A fire pump foundation may seem like a simple structural element, but it plays a vital role in the overall performance, reliability, and compliance of fire protection systems. Adhering to NFPA 20, ACI, and manufacturer recommendations ensures that the pump remains stable, aligned, and free from vibration throughout its service life.

In summary, an ideal fire pump foundation should be:

Heavy enough to resist vibration,

Precisely leveled for proper alignment,

Properly cured and grouted, and

Regularly inspected for long-term stability.

For any fire protection project, following the correct fire pump foundation design standard is not just a recommendation — it’s a necessity for safety, performance, and compliance.