In the field of fire protection, reliability is non-negotiable. Every component—from the control panel to the last sprinkler head—must function exactly as designed under pressure. One crucial yet often misunderstood aspect of fire pump performance is fire pump runout. Understanding what runout is, how it occurs, and why it matters is essential for engineers, contractors, and facility managers who aim to ensure consistent water pressure and flow during fire emergencies.

Fire pump runout refers to the maximum flow rate a pump can deliver under the least amount of pressure, typically when the discharge pressure is at its lowest point on the pump performance curve. It represents the end of the pump curve, where the pump operates beyond its rated capacity.

In simple terms, runout happens when the pump discharges water at a flow rate much higher than its designed operating point, causing the pressure to drop significantly. This situation is often undesirable, as it can lead to system instability and mechanical stress.

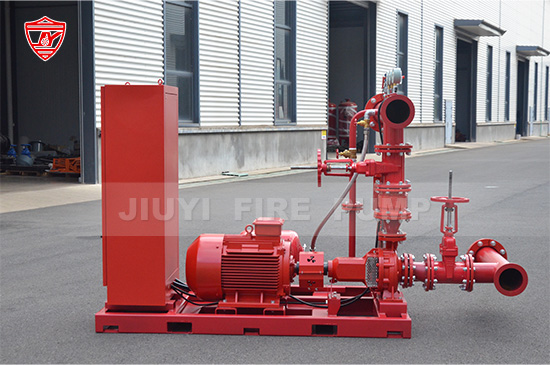

Every fire pump—whether electric-driven or diesel-driven—has a performance curve that shows the relationship between flow (GPM or L/min) and head (pressure). The rated point is where the pump is expected to operate most efficiently, while the runout point lies far to the right of this curve.

Fire pump runout typically occurs under certain conditions where system resistance is too low, such as:

Open or broken piping systems – A burst pipe or open valve downstream can drastically reduce resistance, allowing the pump to discharge more water than intended.

Incorrect system design – Poorly sized discharge piping, oversizing of pumps, or inadequate friction loss calculations can push pumps toward runout conditions.

Improper testing or operation – During commissioning or maintenance tests, when discharge valves are wide open or flow meters are improperly used, the pump can momentarily reach its runout point.

Low static head or gravity-fed systems – When pumps draw from sources with minimal static lift and the system offers little back pressure, flow can easily exceed rated values.

While momentary runout may occur during testing, continuous operation at runout is a red flag that requires immediate correction.

At runout, a fire pump operates under extreme hydraulic conditions. The impeller spins faster than optimal to maintain excessive flow, causing vibration, bearing stress, and shaft deflection. This results in premature wear, seal failure, and possible bearing overheating.

When flow exceeds design limits, suction pressure may drop below vapor pressure, causing cavitation. This not only erodes impeller surfaces but also reduces overall efficiency, leading to long-term performance degradation.

A pump running at runout delivers high flow but low pressure—exactly the opposite of what a fire protection system needs. This could result in insufficient water pressure at remote sprinklers or hose valves, compromising firefighting effectiveness.

NFPA 20, the standard for fire pump installation, specifies that pumps must be selected to provide adequate pressure at required flows. A pump operating near runout conditions violates this principle, indicating poor system design or selection.

Operating a pump beyond its efficient range consumes more energy and increases maintenance frequency. Bearings, seals, and couplings wear out faster, raising long-term operating costs.

To detect or predict fire pump runout, engineers refer to the pump performance curve provided by the manufacturer.

The left side of the curve represents shutoff head (no flow, maximum pressure).

The middle section represents the best efficiency point (BEP), where the pump runs smoothly and efficiently.

The rightmost section is the runout region, where flow increases but pressure drastically drops.

Runout flow is typically 140–150% of the rated flow for most centrifugal fire pumps. NFPA 20 requires that pumps operate without exceeding manufacturer limits up to 150% of rated capacity. Operating beyond this point risks instability, vibration, and damage.

Choosing the correct pump for the application is the most effective way to avoid runout. The selection should consider total head, required flow rate, and system friction losses. Working closely with a UL listed and NFPA 20 compliant manufacturer ensures that the pump’s curve matches real system conditions.

Ensure that piping systems, valves, and fittings are correctly sized to maintain sufficient back pressure. If the discharge piping is too large or the system resistance too low, the pump will move excessive water.

In some cases, installing flow-limiting devices—such as orifice plates or flow control valves—can prevent the pump from exceeding its safe flow range. However, these should be applied cautiously and in accordance with fire protection standards.

Regular performance testing helps detect potential runout conditions before they cause damage. During annual flow tests, technicians should record flow, pressure, and power data, comparing them against the manufacturer’s performance curve.

Many system designers oversize pumps to “be safe,” but this often leads to runout or inefficient operation. A properly sized pump ensures optimal pressure at required flow rates without risking over-discharge.

During routine testing, fire pumps may temporarily reach near-runout flow rates. This is acceptable under controlled testing conditions, provided the pump is not sustained in that state.

Best practices during testing include:

Gradually open test valves to reach 150% of rated flow, then close them slowly.

Monitor vibration, noise, and pressure readings.

Record suction and discharge pressures at each test point.

Compare results to the certified performance curve to identify deviations.

If the pump consistently produces excessive flow at reduced pressure, it may indicate worn impellers, incorrect settings, or system design issues.

Ignoring runout can have serious operational and safety consequences:

System failure during a fire emergency due to inadequate pressure.

Frequent mechanical breakdowns, leading to costly repairs.

Reduced pump lifespan, requiring early replacement.

Regulatory non-compliance, which can affect insurance and safety certifications.

Fire protection systems depend on balanced hydraulic performance. A pump that cannot maintain stable operation under real-world conditions poses a risk not only to property but also to lives.

Consider a high-rise building equipped with a 750 GPM, 100 PSI fire pump. During a flow test, engineers observe the pump delivering 1,150 GPM at only 60 PSI. This indicates that the pump is operating near or at runout. The likely causes could include:

Overly large discharge piping reducing system resistance.

Incorrect system head calculation during design.

Worn impeller increasing flow capability.

The solution would be to verify system resistance, recalibrate test instruments, and confirm the impeller size with the manufacturer.

Fire pump runout is more than just a technical term—it’s a performance boundary that separates safe operation from potential failure. Understanding this concept helps engineers, facility owners, and fire protection professionals design and maintain reliable systems that deliver the right flow and pressure when needed most.

By selecting properly sized pumps, maintaining system balance, and adhering to NFPA 20 standards, you can prevent runout conditions and ensure your fire protection system remains dependable in every emergency.