In modern cities, where residential and commercial buildings stand side by side, the demand for efficient fire protection systems is critical. However, one of the most common challenges faced by engineers and building owners is fire pump noise. The low-frequency hum and vibration from a running fire pump can travel through walls and structures, causing discomfort to occupants and even violating local noise regulations.

As a manufacturer of fire pumps, we understand that achieving both safety and comfort is essential in urban projects. This article will explore the causes of fire pump noise, and provide practical strategies to reduce it—from proper design and installation to isolation techniques and maintenance best practices.

To effectively reduce fire pump noise, it’s important to understand where it comes from. Typically, noise and vibration arise from three primary sources:

1.1 Mechanical Noise

This originates from the moving components of the pump and driver (electric motor or diesel engine). The pump impeller rotation and motor bearings can create mechanical hums, especially if not properly aligned.

1.2 Hydraulic Noise

Hydraulic noise is caused by turbulence in the water flow, especially if the suction and discharge piping are poorly designed. Cavitation—when vapor bubbles form and collapse within the pump—also contributes to sharp noise peaks.

1.3 Structural and Vibration Noise

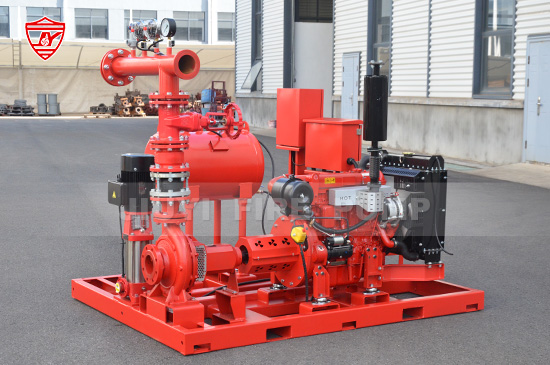

Vibration is transmitted through the pump base into the floor and surrounding walls. In rigid building structures, this can amplify the perceived noise level. Diesel-driven pumps also add exhaust and combustion noise.

Urban installations—such as hospitals, residential towers, and office complexes—often have limited space and thin partitions. This makes noise control not only a comfort issue but also a compliance matter. Excessive noise can lead to:

Disturbance for residents or patients in nearby rooms.

Complaints or penalties due to exceeding noise limits set by local authorities.

Premature wear and tear from continuous vibration, which can affect pump performance and reliability.

Reduced property value if mechanical noise issues persist.

A well-designed fire pump system should not only deliver reliable fire protection but also operate quietly within its environment.

Noise control starts at the design stage. When engineers and building planners integrate acoustic considerations early, most problems can be avoided.

3.1 Choose the Right Pump Type

Selecting a pump that matches system requirements avoids over-speeding or cavitation—two major causes of noise. For example, end suction and split-case pumps are typically quieter when properly sized.

3.2 Optimize Room Layout

Locating the fire pump room away from occupied spaces, such as bedrooms or offices, can significantly reduce the impact of noise. Where possible, situate the pump room near service or parking areas.

3.3 Use Flexible Connections

Flexible pipe connectors on suction and discharge lines prevent vibration from transmitting into the piping system. High-quality flexible joints are critical in urban installations.

3.4 Install a Proper Base and Foundation

The foundation should be massive enough to absorb vibration. A reinforced concrete base with vibration isolation pads can help decouple the pump set from the building structure.

3.5 Consider Acoustic Enclosures

For diesel-driven pumps, installing an acoustic canopy or enclosure reduces engine noise by 20–30 dB(A). These enclosures should have proper ventilation for engine cooling while minimizing sound leakage.

Even with good design, vibration can still travel through the structure. Here are proven solutions used in professional installations:

4.1 Spring Isolators and Pads

Mounting the fire pump and motor on spring isolators reduces structure-borne vibration. Rubber or neoprene pads can also be placed between the base frame and the floor to absorb high-frequency noise.

4.2 Flexible Couplings

A properly aligned flexible coupling between the motor and pump reduces mechanical noise. Misalignment is one of the most common causes of excessive vibration.

4.3 Acoustic Panels and Barriers

Lining the pump room walls and ceilings with sound-absorbing materials such as perforated panels or mineral wool boards can effectively reduce reflected noise within the room.

4.4 Isolated Piping Supports

Use vibration-isolated hangers and supports to prevent noise transmission through the building’s piping system.

4.5 Silencers for Diesel Engines

Install high-performance exhaust silencers to reduce combustion and exhaust noise in diesel-driven systems. Proper exhaust routing also minimizes reverberation through walls.

Even the best design can fail to maintain quiet operation without regular maintenance. Noise is often the first sign that a pump needs attention.

5.1 Monitor and Record Noise Levels

Periodic measurement of vibration and sound levels helps detect abnormal conditions early. Sudden increases often indicate bearing wear, misalignment, or cavitation.

5.2 Ensure Proper Alignment

Shaft misalignment between the motor and pump increases noise and vibration. Alignment should be checked after installation and routinely during service.

5.3 Lubricate Bearings Correctly

Over- or under-lubrication can cause bearing noise. Follow the manufacturer’s recommended schedule and use the correct type of lubricant.

5.4 Check for Cavitation

Cavitation produces a distinct rattling sound and can damage impellers. Ensuring proper suction conditions and avoiding excessive pump speed helps prevent it.

5.5 Maintain Engine and Accessories

For diesel fire pumps, regular maintenance of exhaust systems, engine mounts, and cooling systems ensures quieter operation and better longevity.

In many urban projects, the fire pump room already exists, and replacing the entire system is not feasible. In such cases, targeted retrofitting can achieve significant noise reduction.

6.1 Add Isolation Pads or Bases

Installing isolation pads under the existing base frame is often the simplest and most effective solution for vibration reduction.

6.2 Reinforce the Room Structure

Applying acoustic insulation panels on walls and ceilings helps contain airborne noise within the pump room.

6.3 Install Flexible Piping Connectors

Retrofitting flexible connectors on the suction and discharge lines can dramatically cut down structure-borne vibration.

6.4 Modify Ventilation Systems

Adding silencers or acoustic louvers on ventilation ducts prevents noise from escaping into nearby occupied areas.

Fire pump manufacturers play an essential role in minimizing noise from the start. Advanced engineering and testing allow manufacturers to offer pumps designed for smooth, quiet operation.

At Better Technology Group, our fire pump systems are engineered with:

Precision-balanced impellers to minimize vibration.

High-quality bearings and coupling alignment for reduced mechanical noise.

Optional soundproof housings and base isolation systems for sensitive installations.

Comprehensive performance testing, ensuring low noise and reliable operation under full load conditions.

By integrating these design principles, building owners and contractors can ensure their fire protection systems meet both safety and acoustic comfort requirements.

Reducing fire pump noise in urban installations is a multidisciplinary effort involving design, equipment selection, installation, and maintenance. With growing emphasis on comfort and environmental standards, low-noise fire pump systems are no longer a luxury—they are a necessity.