Fire pumps are mission-critical equipment in fire protection systems, designed to operate reliably in emergencies when human lives and property depend on them. However, in humid environments such as coastal regions, tropical climates, underground pump rooms, and industrial facilities with high moisture levels, corrosion becomes one of the most common and destructive threats to fire pump reliability. Corrosion not only shortens equipment lifespan but also increases the risk of system failure during a fire event, leading to serious safety, legal, and financial consequences.

For manufacturers, contractors, consultants, and end users in the fire safety field, understanding how to prevent fire pump corrosion is essential for long-term system reliability. This article provides a practical and engineering-focused guide to corrosion risks, material selection, environmental control, protective treatments, and preventive maintenance strategies for fire pumps installed in humid environments.

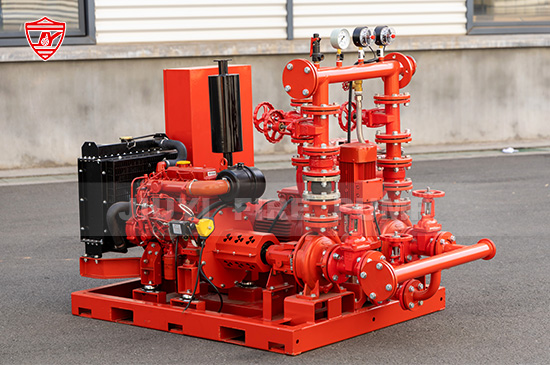

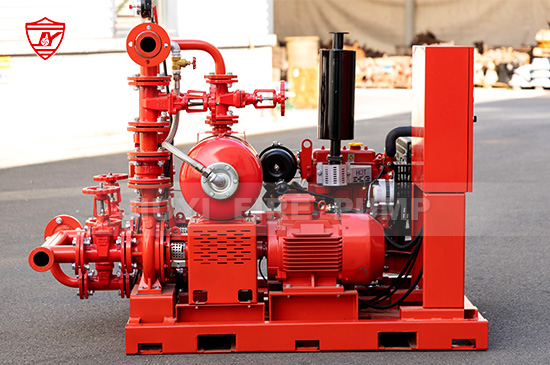

Corrosion is an electrochemical reaction that occurs when metal surfaces are exposed to oxygen and moisture. In humid environments, moisture remains present in the air for extended periods, creating ideal conditions for rust and corrosion to develop on metal components. Fire pumps, whether electric motor-driven or diesel engine-driven, contain multiple vulnerable parts including pump casings, shafts, impellers, fasteners, base frames, control panels, and piping connections.

In coastal and marine environments, salt particles in the air further accelerate corrosion. Chloride ions penetrate protective oxide layers on metal surfaces, causing localized pitting and crevice corrosion. In poorly ventilated pump rooms, condensation can form on metal surfaces due to temperature differences between indoor air and cold pipes or pump bodies. Over time, this continuous exposure leads to material degradation, reduced mechanical strength, leakage, seizure of moving parts, and electrical failures.

The challenge is not only surface rust but internal corrosion within pump housings, bearings, and cooling systems. If corrosion is not addressed proactively, fire pump performance may degrade gradually, making failures harder to detect until the system is tested under full load or during an actual fire emergency.

One of the most effective ways to prevent fire pump corrosion is to start with proper material selection at the design and manufacturing stage. Not all metals perform equally in humid or corrosive environments. Fire pump manufacturers and project designers should carefully evaluate environmental conditions and specify materials accordingly.

Stainless steel components offer significantly better corrosion resistance compared to standard carbon steel. Stainless steel shafts, fasteners, and auxiliary parts can reduce rust formation in high-humidity installations. For impellers and pump casings, materials such as bronze, ductile iron with protective coatings, or specially treated cast iron provide improved durability.

For diesel engine fire pumps, cooling systems, exhaust components, and mounting frames should also be designed with corrosion resistance in mind. Electrical enclosures and control panels should use corrosion-resistant enclosures and sealed cable entries to prevent moisture ingress.

Material selection is particularly critical for fire pumps installed in coastal zones, offshore platforms, chemical plants, and wastewater facilities. In these environments, upgrading materials at the procurement stage can significantly reduce total lifecycle costs by minimizing corrosion-related failures and maintenance interventions.

Protective coatings form a critical barrier between metal surfaces and corrosive environments. High-quality anti-corrosion coatings can dramatically extend the service life of fire pumps in humid environments. Manufacturers typically apply factory coatings to pump bodies and base frames, but additional site-applied coatings may be necessary depending on environmental severity.

Epoxy-based coatings provide strong chemical resistance and excellent adhesion, making them suitable for pump casings and steel structures. Polyurethane topcoats offer enhanced resistance to moisture and ultraviolet exposure for outdoor installations. Zinc-rich primers can be used to provide sacrificial protection, particularly for steel components exposed to condensation and splashing water.

It is important that coatings are applied according to proper surface preparation standards. Poor surface cleaning, inadequate thickness, or improper curing can compromise coating performance and allow corrosion to initiate beneath the protective layer. For long-term reliability, coating systems should be selected based on environmental classification, humidity levels, and potential chemical exposure in the pump room.

Periodic inspection and touch-up of coatings should be part of routine maintenance. Any damaged or peeling areas should be repaired promptly to prevent corrosion from spreading under the coating film.

Environmental control plays a vital role in preventing corrosion. Fire pump rooms are often located in basements, underground levels, or separate buildings that may experience poor ventilation and high humidity. Without proper design and environmental management, even corrosion-resistant materials and coatings can deteriorate prematurely.

Proper ventilation helps reduce moisture accumulation and prevents condensation on metal surfaces. Natural ventilation may be sufficient in some climates, but in highly humid regions, mechanical ventilation or dehumidification systems are recommended. Maintaining relative humidity below levels that promote condensation can significantly slow corrosion processes.

Drainage design is equally important. Water leakage, flooding, or routine testing discharge can lead to standing water around fire pump equipment. Floor drains, sloped floors, and proper water management systems help ensure that moisture does not remain in contact with metal components for extended periods. Fire pumps should be installed on raised concrete plinths or base frames to avoid direct contact with damp floors.

Temperature control also affects corrosion. Large temperature swings increase condensation risk on cold metal surfaces. Maintaining stable indoor temperatures can reduce moisture buildup and extend equipment life.

Preventive maintenance is the most reliable long-term strategy for preventing corrosion-related failures. Regular inspections allow early detection of rust, coating damage, moisture ingress, and material degradation before they compromise fire pump performance.

Routine visual inspections should include pump casings, base frames, fasteners, coupling guards, electrical enclosures, and piping interfaces. Any signs of rust, discoloration, flaking paint, or moisture accumulation should be documented and addressed promptly. Mechanical components such as shafts and bearings should be checked for corrosion-related wear or stiffness.

Lubrication practices also influence corrosion. Proper lubrication of bearings and moving parts helps prevent moisture ingress and surface oxidation. However, excessive lubrication or contaminated lubricants can trap moisture and accelerate corrosion. Maintenance teams should follow manufacturer-recommended lubrication schedules and use appropriate corrosion-inhibiting lubricants.

Periodic functional testing of fire pumps, as required by fire protection standards, also provides an opportunity to observe abnormal vibrations, noise, or performance issues that may be linked to corrosion. Integrating corrosion checks into standard fire pump inspection routines ensures that corrosion prevention becomes part of daily operational culture rather than an afterthought.

Fire pump corrosion prevention is not limited to the pump itself. The entire fire pump system, including suction and discharge piping, valves, fittings, and pressure tanks, is exposed to humid environments and potential corrosion. Corrosion in these components can lead to leaks, pressure loss, and system inefficiencies.

Piping materials should be selected based on environmental exposure and water quality. Protective coatings, internal linings, and corrosion-resistant alloys can reduce rust formation in both external and internal surfaces. Valve bodies, flanges, and bolts should receive similar protective treatment.

Electrical and control components require special attention. Moisture ingress into motor windings, control panels, and sensors can cause electrical failures that disable fire pump operation. Proper sealing, enclosure ratings, and cable gland protection are essential. Periodic inspection of control cabinets for condensation or corrosion signs helps prevent unexpected failures.

For projects located in consistently humid climates, corrosion prevention should be integrated into system design rather than treated as a maintenance issue alone. Fire pump manufacturers can offer customized solutions such as enhanced coating systems, stainless steel hardware, sealed electrical enclosures, and climate-adapted packaging.

Designers and consultants should consider environmental classification when specifying fire pump systems. Coastal facilities, offshore platforms, ports, and industrial plants with high humidity require higher corrosion protection standards than dry inland installations. Specifying corrosion-resistant materials and environmental control systems at the project planning stage leads to lower operational risk and reduced maintenance costs over the system’s lifecycle.

Lifecycle cost analysis can help project owners understand the long-term value of investing in corrosion protection. While initial costs may be higher, the reduction in unplanned downtime, replacement parts, and emergency repairs often results in significant cost savings over time.

Even the best-designed fire pump systems can suffer corrosion-related failures if maintenance teams lack proper training and awareness. Personnel responsible for fire pump operation and maintenance should be trained to recognize early signs of corrosion and understand the environmental factors that contribute to equipment degradation.

Clear maintenance procedures, inspection checklists, and documentation practices help ensure consistency across maintenance cycles. Recording corrosion observations over time allows maintenance teams to identify trends and implement targeted improvements. Communication between manufacturers, service providers, and end users further enhances long-term corrosion prevention strategies by incorporating field feedback into product design and maintenance planning.

Preventing fire pump corrosion in humid environments is not a single action but a comprehensive strategy that spans design, material selection, protective coatings, environmental control, preventive maintenance, and personnel training. Corrosion is a silent threat that can compromise fire pump reliability long before visible failures occur. For fire safety professionals, ensuring corrosion resistance is a critical part of delivering dependable fire protection systems.

By adopting corrosion-resistant materials, applying high-performance protective coatings, controlling humidity in pump rooms, implementing robust preventive maintenance programs, and designing systems with environmental conditions in mind, fire pump owners and operators can significantly extend equipment lifespan and reduce the risk of failure during critical fire events. In humid environments, proactive corrosion prevention is not optional; it is an essential investment in safety, reliability, and long-term operational confidence.