Regular fire pump inspections are critical to ensuring that fire protection systems operate reliably in an emergency. Annual fire pump inspections are not just a regulatory requirement under NFPA 25—they are also a vital part of maintaining safety, performance, and insurance compliance.

In this article, we’ll guide you through how to properly prepare for an annual fire pump inspection, what inspectors typically look for, and how you can avoid common pitfalls that lead to system deficiencies or failures.

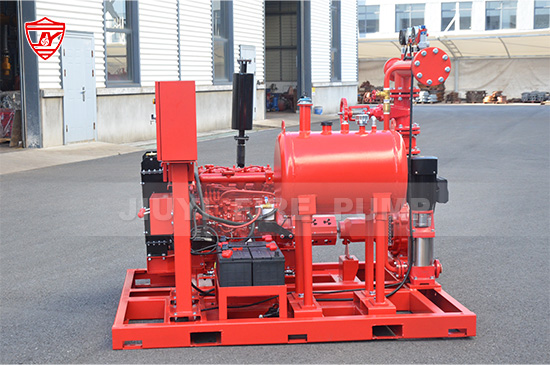

Fire pumps are the heart of a fire protection system, ensuring consistent water pressure during a fire emergency. Over time, wear, corrosion, or neglect can reduce performance and reliability.

The annual inspection verifies that the fire pump system meets the operational standards set by NFPA 25: Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems.

Failing to maintain or prepare for this inspection can result in:

Non-compliance penalties or failed certifications

Reduced insurance coverage

Increased risk of system malfunction during a fire

Costly emergency repairs

Proper preparation helps ensure a smooth inspection process, minimizes downtime, and provides peace of mind that your fire protection system will perform as intended.

Before the inspection date, review your fire pump’s maintenance and testing logs for the past year. NFPA 25 requires that weekly, monthly, and annual tests be documented, including flow tests, pressure readings, and controller checks.

Inspectors will ask for these records to verify that routine checks have been performed. Missing or incomplete documentation can lead to a failed inspection—even if your system operates correctly.

Checklist:

Verify all weekly and monthly inspection logs are complete

Ensure annual performance test reports are available

Record all maintenance or repairs performed

Keep manufacturer data sheets and specifications accessible

Having organized and up-to-date records demonstrates compliance and professionalism, and helps inspectors complete their review efficiently.

The fire pump room’s condition directly affects equipment performance and longevity. A clean, well-maintained, and accessible space reflects a proactive maintenance culture and simplifies inspection.

Pre-inspection tasks:

Ensure adequate lighting and ventilation

Confirm that the pump room is dry and free from leaks

Verify that doors are unlocked and pathways are clear

Remove any stored materials that block equipment access

Check that temperature is within manufacturer-recommended limits (usually above 4°C or 40°F to prevent freezing)

Inspectors often cite cluttered or poorly maintained pump rooms as violations, so this simple preparation step can significantly improve your inspection results.

Whether your fire pump is electric-driven or diesel-driven, its power and control systems must be fully operational.

For Electric Fire Pumps:

Inspect the main controller for dust or corrosion

Verify that power supply connections are secure

Ensure all indicator lights and alarms function properly

Confirm the automatic and manual start modes operate correctly

For Diesel Fire Pumps:

Check fuel level and condition

Inspect batteries and cables for corrosion

Test the engine’s automatic start and stop sequence

Verify oil level, coolant, and exhaust system

A quick pre-test of the controller and starting mechanism can help identify issues before the inspection, avoiding an embarrassing failure during the test.

All valves, gauges, and sensors play critical roles in ensuring correct fire pump performance. Inspectors will check that these components are in their proper position and functioning accurately.

Preparation checklist:

Verify suction and discharge valves are open and labeled correctly

Check pressure gauges for accuracy and readability

Ensure relief valves are installed and operational

Inspect check valves for proper seating and absence of leakage

Regularly exercising these valves throughout the year prevents them from seizing or failing during inspection.

Running a preliminary fire pump test before the official inspection helps you identify potential performance issues in advance.

During the test:

Record suction and discharge pressures

Observe pump operation for unusual noises or vibrations

Verify automatic starting and stopping sequences

Monitor flow and pressure readings to ensure they meet the rated capacity

If the readings are below manufacturer specifications, investigate potential causes such as clogged strainers, worn impellers, or air leaks in suction lines.

By performing this internal check a few days before the scheduled inspection, your team can correct small issues that might otherwise lead to a failed inspection.

NFPA 25 provides clear guidelines for inspection frequency, procedures, and documentation. Reviewing these requirements ensures you’re aligned with the latest standards.

Key NFPA 25 references for fire pump systems include:

Chapter 8 – Fire Pumps: outlines inspection, testing, and maintenance procedures

8.3.7 – Annual Flow Test: specifies testing flow and pressure at 100%, 150%, and shutoff head

8.3.5 – Controller Inspection: details requirements for electric and diesel controllers

Even minor deviations from NFPA 25 can lead to compliance issues. Reviewing these sections helps ensure your preparation aligns with recognized best practices.

Effective communication with your fire protection contractor or inspection agency can save time and prevent misunderstandings.

Before the inspection:

Confirm the inspection date and expected duration

Provide access to all areas and equipment

Share previous inspection reports and maintenance records

Assign a facility representative to accompany the inspector

This collaboration ensures that any questions can be answered immediately, reducing the risk of delays or repeated visits.

Many facilities fail their annual inspection due to avoidable issues. Address these in advance to ensure compliance.

Common deficiencies include:

Obstructed suction or discharge piping

Corroded pump components

Leaking packing glands

Inoperative gauges or alarms

Inadequate recordkeeping

A simple visual check of these components can prevent unexpected failures during the inspection.

Even well-maintained systems may require minor adjustments after inspection. Prepare a process for reviewing inspection findings and implementing corrective actions promptly.

Post-inspection steps:

Review the inspection report in detail

Prioritize any corrective recommendations

Schedule repairs or replacements as needed

Update maintenance records and compliance files

Maintaining this cycle of review and correction ensures long-term system reliability and compliance year after year.

Your inspection preparation is only as strong as the quality of your equipment and support. Working with a certified fire pump manufacturer ensures your system meets UL, FM, and NFPA 20 standards.

A trusted manufacturer provides:

Guidance on inspection readiness

Replacement parts and service support

Technical documentation and training

Long-term reliability through certified components

At Better Technology Group, we manufacture and supply UL Listed, NFPA 20 compliant fire pump systems, including electric, diesel, and jockey pumps. Our commitment to quality and safety ensures your system performs reliably through every inspection and beyond.

Preparing for an annual fire pump inspection is not just a regulatory task—it’s an essential part of protecting lives and property. By organizing your documentation, checking key components, performing pre-tests, and staying aligned with NFPA 25 standards, you can ensure a successful inspection with minimal disruptions.

A proactive approach demonstrates your dedication to fire safety and builds confidence that your system will perform flawlessly when it’s needed most.