Fire pump systems are the backbone of any fixed fire protection system. Whether protecting industrial plants, high-rise buildings, warehouses, or critical infrastructure, fire pumps must operate reliably when a fire occurs. However, one of the most overlooked risks in fire protection design is grid failure. Fires often cause power outages, and natural disasters or electrical faults can disable the main power supply at the worst possible moment.

Ensuring continuous fire pump operation during grid failure is not optional—it is a fundamental requirement of fire safety engineering. This article explores how to design, select, and maintain fire pump systems that remain fully operational when utility power is lost.

Why Grid Failure Is a Critical Risk for Fire Pump Systems

Power outages frequently coincide with fire events. Electrical faults can ignite fires, and fires themselves can damage transformers, switchgear, or incoming power lines. If a fire pump depends solely on the utility grid, the system may fail exactly when it is needed most.

Fire safety codes and standards worldwide recognize this risk. Reliable fire pump operation during grid failure is essential to:

-

Maintain adequate water pressure for sprinklers and hydrants

-

Support firefighting operations

-

Protect lives, assets, and continuity of operations

-

Meet regulatory and insurance requirements

A fire pump system must therefore be designed with redundancy, independence, and resilience in mind.

Understanding Fire Pump Power Supply Requirements

Fire pumps are typically driven by one of three power sources:

-

Electric motor-driven fire pumps

-

Diesel engine-driven fire pumps

-

Steam turbine-driven fire pumps

In most modern applications, electric and diesel fire pumps dominate the market. Each has specific implications for grid failure scenarios.

Electric fire pumps rely on a stable electrical supply. Without proper backup arrangements, they are vulnerable to utility outages. Diesel fire pumps, on the other hand, are inherently independent of the electrical grid and are often chosen specifically for this reason.

Electric Fire Pumps and Grid Failure Challenges

Electric fire pumps are widely used due to their lower initial cost, compact footprint, and minimal emissions. However, they are only as reliable as their power supply.

During grid failure, electric fire pumps face several risks:

-

Total loss of power if no backup source is available

-

Voltage drops or unstable power affecting motor performance

-

Delayed startup if automatic transfer systems fail

To ensure operation during grid failure, electric fire pumps must be supported by a compliant emergency power solution.

Emergency Power Solutions for Electric Fire Pumps

Dedicated Emergency Generators

The most common solution is a dedicated emergency generator designed specifically for fire pump operation. This generator must:

-

Be sized to handle the locked-rotor current of the fire pump motor

-

Start automatically upon power failure

-

Supply power without manual intervention

-

Be physically protected from fire and environmental damage

Fire pump generators should not be shared with non-essential loads. Fire protection equipment must always have priority.

Dual Power Feeds

In some facilities, two independent utility power sources may be available. Dual feeders reduce the likelihood of total power loss but do not eliminate risk entirely, especially during large-scale outages or disasters.

Fire Pump Controllers and Transfer Systems

Fire pump controllers play a critical role in ensuring seamless operation during grid failure. Properly designed controllers can:

-

Automatically detect power loss

-

Transfer to emergency power sources

-

Ensure correct motor starting sequence

-

Provide alarms and status indication

The reliability of the controller is just as important as the pump and power source.

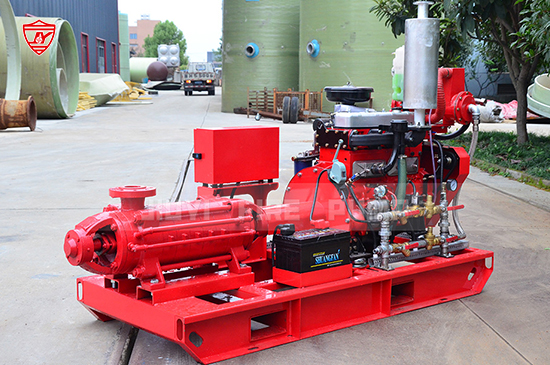

Diesel Fire Pumps: A Proven Solution for Grid Independence

Diesel engine-driven fire pumps are widely regarded as the most reliable option for ensuring fire pump operation during grid failure. Because they do not depend on external electrical power for operation, they provide true independence.

Key advantages of diesel fire pumps include:

-

Immediate availability during power outages

-

High reliability in remote or unstable grid regions

-

Compliance with stringent fire safety requirements

-

Suitability for critical facilities

Diesel fire pumps are commonly used in:

-

Data centers

-

Oil and gas facilities

-

Airports and seaports

-

High-risk industrial plants

-

Locations with unreliable electrical infrastructure

Key Design Considerations for Diesel Fire Pumps

While diesel fire pumps offer independence, proper design and maintenance are essential.

Fuel Supply Reliability

A diesel fire pump is only as reliable as its fuel supply. Best practices include:

-

On-site fuel storage sized for minimum run-time requirements

-

Dedicated fuel tanks exclusively for the fire pump

-

Fuel quality management to prevent contamination

-

Redundant fuel lines where applicable

Engine Cooling and Ventilation

Diesel engines generate significant heat. Fire pump rooms must be designed to ensure:

-

Adequate ventilation

-

Proper exhaust routing

-

Stable operating temperatures

-

Protection from smoke and fire exposure

Battery and Starting System

Diesel fire pumps rely on battery systems for starting. Redundancy is critical:

-

Dual battery systems

-

Automatic battery chargers

-

Regular testing and replacement schedules

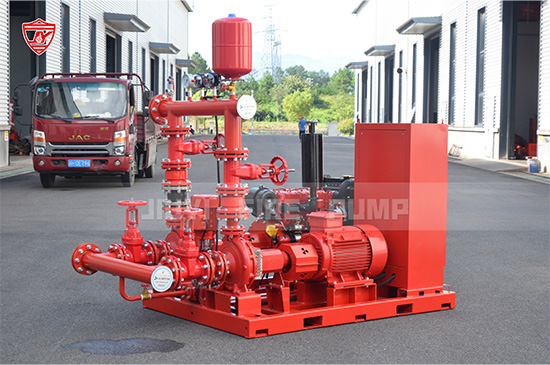

Hybrid Fire Pump Configurations for Maximum Reliability

In high-value or mission-critical facilities, a combination of electric and diesel fire pumps is often used. This approach provides layered redundancy.

Typical hybrid configurations include:

-

Electric fire pump as the primary unit

-

Diesel fire pump as the standby unit

-

Automatic changeover based on power availability

This design ensures that fire protection remains functional regardless of grid conditions, maintenance activities, or unexpected failures.

Compliance with Fire Safety Standards

Ensuring fire pump operation during grid failure is not just a best practice—it is a code requirement in many jurisdictions.

Fire pump systems must be designed and installed in accordance with recognized standards such as:

-

Fire pump power source independence

-

Automatic starting requirements

-

Minimum run-time under full load

-

Separation of fire protection systems from non-essential services

Manufacturers, designers, and installers must work together to ensure that the entire system—not just the pump—meets compliance requirements.

Installation and Room Design Considerations

The physical environment of the fire pump system has a direct impact on its reliability during grid failure.

Important considerations include:

-

Fire-rated pump rooms

-

Flood protection and drainage

-

Seismic restraints where required

-

Clear access for inspection and maintenance

-

Separation from electrical rooms vulnerable to fire damage

A well-designed fire pump room enhances survivability and operational reliability during emergencies.

Testing, Maintenance, and Preparedness

Even the best-designed fire pump system can fail if it is not properly maintained.

To ensure readiness during grid failure:

-

Conduct regular no-flow and full-load fire pump tests

-

Simulate power failure conditions during testing

-

Verify automatic transfer and startup sequences

-

Inspect fuel systems, batteries, and controllers

-

Keep detailed maintenance and test records

Testing under realistic conditions is the only way to confirm that the system will perform when needed.

The Manufacturer’s Role in Fire Pump Reliability

As a fire pump manufacturer, quality, compliance, and system integration are critical responsibilities. Reliable fire pump operation during grid failure depends on:

-

Robust pump and engine design

-

Certified controllers and accessories

-

Clear technical documentation

-

Support for system designers and contractors

A manufacturer with deep experience in fire protection understands that fire pumps are not ordinary pumps—they are life safety equipment.

Conclusion

Grid failure is one of the most serious threats to fire pump reliability, yet it is entirely manageable with the right approach. By selecting appropriate fire pump types, designing compliant emergency power solutions, and maintaining systems rigorously, fire pump operation can be assured even under the most challenging conditions.

Whether through diesel fire pumps, dedicated emergency generators, or hybrid system designs, the goal remains the same: uninterrupted fire protection when it matters most. Ensuring fire pump operation during grid failure is not just about meeting codes—it is about safeguarding lives, property, and trust in fire safety systems.