Fire pumps are the heart of a fire protection system, ensuring water is delivered with sufficient pressure during emergencies. While most people focus on the motor, impeller, or controller, one of the most critical components determining pump reliability and service life is often overlooked — the bearings.

Bearings play a crucial role in supporting rotating parts, minimizing friction, and ensuring smooth operation. Proper bearing selection, lubrication, and maintenance are vital to preventing costly breakdowns and ensuring your fire pump system performs flawlessly when needed most.

In this article, we’ll cover everything you need to know about fire pump bearings and lubrication — from types and functions to maintenance best practices and common problems.

Bearings are mechanical components that reduce friction between moving parts and support the rotating shaft. In a fire pump, bearings stabilize the shaft that connects the impeller to the motor or engine, allowing smooth and precise rotation.

Without properly functioning bearings, the pump would experience excessive vibration, heat buildup, and premature wear. These issues can lead to performance loss or, in the worst case, catastrophic failure during an emergency.

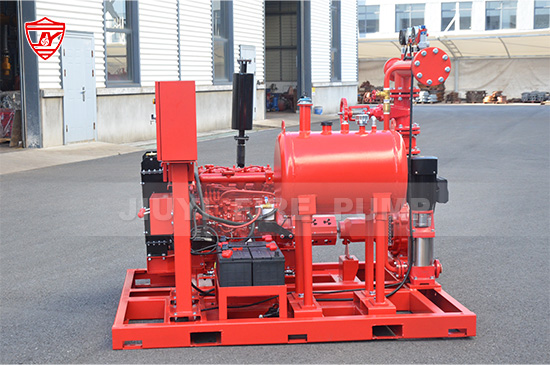

In a typical fire pump assembly, bearings are found in both electric motor-driven and diesel engine-driven units. The bearing configuration depends on the pump design — end suction, split case, or vertical turbine — and its operational conditions.

Different fire pumps use specific bearing types based on design, speed, and load. Here are the most common types:

Ball bearings use spherical rolling elements that reduce friction efficiently and handle moderate radial and axial loads. They are commonly found in electric motor fire pumps due to their precision and quiet operation.

Roller bearings feature cylindrical rollers that provide greater load-carrying capacity than ball bearings. They are ideal for heavy-duty pumps that operate under higher radial loads, such as horizontal split-case fire pumps.

Thrust bearings are designed to support axial loads along the shaft direction. Vertical turbine fire pumps often rely on thrust bearings to handle the downward thrust created by the impeller stack.

Sleeve (or journal) bearings are used in certain applications requiring low noise and long life under moderate loads. They rely on a film of lubricant between the shaft and bearing surface to minimize friction.

Understanding the specific bearing type and its purpose helps guide appropriate maintenance and lubrication practices.

Lubrication is the lifeline of any bearing. It minimizes friction, dissipates heat, and protects metal surfaces from corrosion. Proper lubrication also helps seal out contaminants such as dust and water, extending bearing life.

Without adequate lubrication, the metal surfaces of the bearing and shaft can make direct contact, leading to severe wear, overheating, and eventual failure. In fire pumps, such failure can cause vibration, noise, and reduced hydraulic performance.

Reduces friction and wear

Prevents corrosion

Controls temperature

Protects against contaminants

Extends bearing service life

Fire pump bearings can be lubricated using grease or oil, depending on pump design and manufacturer specifications. Both methods have advantages, and the choice often depends on operating speed, temperature, and environmental conditions.

Grease is the most common lubricant for fire pump bearings. It consists of oil thickened with soap or other agents.

Advantages:

Simple application and sealing

Lower maintenance frequency

Effective against moisture and dust ingress

Typical Applications:

End suction fire pumps

Electric motor bearings

Maintenance Tip:

Avoid over-greasing. Too much grease can increase friction, cause overheating, and damage seals. Always follow the manufacturer’s recommended re-lubrication intervals and amounts.

Oil lubrication is used for bearings operating at higher speeds or loads, such as large horizontal split case or vertical turbine fire pumps.

Advantages:

Better heat dissipation

Continuous lubrication flow

Suitable for high-speed or high-temperature environments

Common Methods:

Oil bath lubrication

Oil mist or ring lubrication

Maintenance Tip:

Monitor oil levels regularly and replace the oil when it becomes dark or contaminated. Always use the oil grade recommended by the pump manufacturer.

Maintaining fire pump bearings is not just about adding lubricant — it requires careful inspection, recordkeeping, and preventive action.

The NFPA 20 standard specifies maintenance intervals and inspection requirements for fire pumps. Always refer to both NFPA 20 and the specific pump manufacturer’s maintenance manual for guidance.

Inspect bearings for signs of wear, vibration, or unusual noise during weekly or monthly pump tests. Overheating, leakage, or irregular sounds may indicate bearing or lubrication problems.

Contaminated or degraded lubricant can cause premature bearing failure. Regularly check for:

Oil discoloration

Presence of metal particles

Grease hardening or separation

Replace lubricants immediately if contamination is found.

If the fire pump is stored for an extended period before installation, ensure bearings are properly lubricated and protected from moisture or dust. Rotate the shaft periodically to distribute lubricant evenly.

Document every lubrication and inspection activity. Tracking lubricant type, date, and observations helps detect trends and plan proactive maintenance.

Even with proper maintenance, certain factors can lead to bearing failure. Recognizing these issues early helps prevent system downtime.

The most common cause of bearing failure is inadequate lubrication. Without enough lubricant, friction increases, leading to excessive heat and wear.

Too much grease can cause churning and increased temperature, damaging seals and reducing efficiency.

Dust, dirt, or moisture entering the bearing housing can cause pitting, corrosion, and accelerated wear.

Improper shaft alignment during installation or operation increases stress on bearings, leading to premature failure.

Excessive load beyond the bearing’s design capacity can deform rolling elements and reduce bearing life.

Operating outside the recommended temperature range can degrade lubricant and reduce bearing performance.

Operators should be alert to early warning signs that may indicate bearing issues:

Abnormal noise or vibration during operation

Unusual increase in bearing temperature

Grease leakage around seals

Reduced pump performance or efficiency

Promptly addressing these symptoms helps prevent severe damage and costly repairs.

To ensure reliable long-term operation, apply these best practices:

Use the correct lubricant type and grade recommended by the pump manufacturer.

Maintain a clean environment around bearing housings.

Follow proper re-lubrication intervals and techniques.

Use precision tools for shaft alignment and bearing installation.

Monitor vibration and temperature regularly.

Replace worn or damaged seals promptly.

Preventive care not only saves time and cost but also guarantees that your fire pump will perform efficiently during an emergency.

While daily checks and minor lubrication can be done by facility staff, bearing inspection and replacement should be handled by trained professionals. Certified technicians have the tools and experience to assess bearing condition accurately, detect early-stage issues, and ensure compliance with NFPA standards.

Professional maintenance also ensures that lubricant selection, quantity, and application meet the pump’s specific design and operating conditions.

Bearings and lubrication are small components that make a big difference in fire pump performance. Proper bearing care ensures the pump operates smoothly, efficiently, and reliably in critical moments.

By understanding the types of bearings used, choosing the right lubricant, and following a disciplined maintenance schedule, facility managers and fire safety professionals can greatly extend the life of their fire pump systems.

In fire protection, reliability isn’t optional — it’s essential. Investing time in proper bearing and lubrication maintenance ensures that when a fire emergency occurs, your pump performs exactly as it should.