Fire pumps are at the heart of many fire protection systems. They ensure adequate water pressure and flow is available when needed most—during a fire emergency. Because of their critical role, fire pumps must be properly installed, tested, and maintained according to strict standards such as NFPA 20 and FM Global requirements.

One question that often arises, especially from facility managers, engineers, and maintenance staff, is: Can you run a fire pump without water?

The short and definitive answer is no. Running a fire pump without water, even briefly, can cause severe mechanical damage, jeopardize system performance, and potentially void certifications and warranties. In this article, we will explore why fire pumps must never be run dry, what risks are involved, and the best practices for ensuring safe and reliable operation.

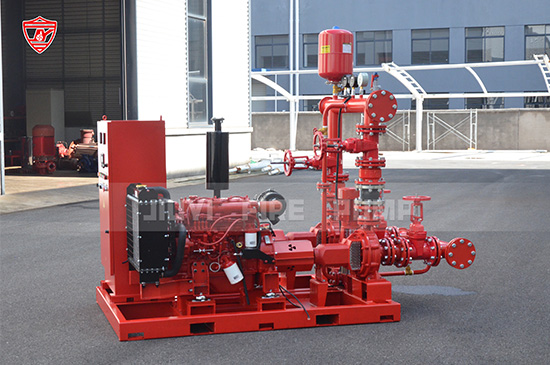

Fire pumps, whether diesel-driven, electric-driven, or vertical turbine designs, are specifically engineered to move water. Their internal components—such as impellers, pump casings, seals, and bearings—rely on water for lubrication and cooling.

Without water, these components are exposed to conditions they were never designed to handle:

Overheating – Water not only moves through the system but also removes heat generated by friction. Without it, temperatures rise rapidly.

Seal Failure – Mechanical seals require a water film for lubrication. Dry operation leads to immediate seal wear and leakage once water is reintroduced.

Impeller Damage – The impeller spins at high speed. If there’s no water, friction and vibration increase, which can warp or crack the impeller.

Casing Wear – Without water cushioning the flow, internal surfaces experience direct abrasion, leading to erosion and costly replacement.

Operating a fire pump without water is not a harmless mistake. Even a short period of dry running can cause lasting damage. Below are the main consequences:

Bearings, seals, and impellers can fail within minutes. Once seals are worn, leaks will occur, reducing pump efficiency and requiring urgent repairs.

UL, FM, and NFPA standards require fire pumps to be tested and operated under water flow conditions. Running a pump dry can result in non-compliance, which affects insurance coverage and legal obligations.

Replacing seals, bearings, or even an entire pump assembly due to dry running is far more expensive than routine maintenance. A single incident can cost thousands of dollars.

The most serious risk: a fire pump that has been damaged due to dry running may fail when needed most, compromising fire safety and human lives.

Although it’s well understood that pumps need water, dry running incidents still occur. Here are some of the most common causes:

Improper commissioning – Running the pump during testing before the water source is connected.

Closed valves – Suction valves accidentally left closed during maintenance.

Blocked suction line – Debris or ice preventing water flow into the pump.

Empty tank or water source – Insufficient supply from a reservoir, tank, or city water main.

Faulty priming in vertical turbine pumps – In some installations, improper priming procedures can cause pumps to start without water.

To avoid the risks of operating a fire pump without water, facilities should follow industry best practices:

Always confirm that the water source is available, whether from a tank, reservoir, or city main. Flow should be tested and verified.

Ensure that suction and isolation valves are fully open before operating the pump. Labeling and lockout systems can prevent mistakes.

Monitoring devices can alert operators if water is not entering the pump correctly, shutting the system down before major damage occurs.

NFPA 20 provides strict requirements for fire pump installation, testing, and operation. Always adhere to these guidelines to maintain compliance.

Human error is a leading cause of dry running. Ensure that staff know the correct procedures for starting and testing fire pumps.

Routine inspections and preventive maintenance help identify potential problems—such as clogged strainers, sediment buildup, or valve misalignment—before they lead to dry operation.

If a pump has been accidentally run dry, immediate action is required:

Shut down the pump immediately – Do not attempt to restart it until a full inspection has been completed.

Inspect seals and bearings – These are the most vulnerable components and may need replacement.

Check for impeller and casing damage – Look for cracks, erosion, or warping.

Flush the system – If dust or debris entered during dry running, clean and flush the pump before reoperation.

Conduct a performance test – Ensure the pump still delivers required flow and pressure.

Consult the manufacturer – Report the incident to the pump supplier or manufacturer for guidance on repair or replacement.

No. Most fire pumps, especially centrifugal fire pumps, are not self-priming. They must have water supplied from a reliable source.

Even a few minutes can cause severe damage. Unlike some industrial pumps designed for short dry runs, fire pumps are not built for it.

Yes. Regardless of the driver (diesel or electric), the pump end itself requires water for safe operation.

Vertical turbine pumps are designed to draw water directly from below ground or tanks, but they must always be submerged. If priming is lost, they can suffer damage similar to centrifugal fire pumps.

Never run a fire pump without water. Doing so causes mechanical damage, loss of certification compliance, and potential failure during emergencies.

Dry running is preventable through proper installation, inspection, and staff training.

Immediate inspection and repair are required if dry running occurs, to restore pump integrity and ensure reliable operation.

The reliability of a fire pump is a matter of life safety. While it may seem like a minor mistake, running a fire pump without water can destroy critical components and put an entire fire protection system at risk. Facility managers, fire safety professionals, and engineers must remain vigilant in ensuring pumps are always operated under correct conditions, with water supply verified before operation.

By following industry standards and best practices, and by educating personnel about the risks, you can ensure that your fire pump will perform flawlessly when it matters most: during a fire emergency.