In any fire protection system, the reliability of a diesel engine fire pump is non-negotiable. These pumps are designed to operate under extreme conditions and must start immediately when required — with no room for mechanical error. One often overlooked yet vital component ensuring this reliability is overspeed protection. It may not sound like the flashiest feature, but without it, a fire pump’s performance — and the entire fire protection system — could be catastrophically compromised.

In this article, we explore what overspeed protection is, why it matters, and how it ensures both compliance and operational integrity in diesel-powered fire pumps.

Overspeed protection refers to a built-in safety mechanism designed to shut down a diesel engine if it exceeds its maximum rated speed. This mechanism prevents engine damage, system failure, and potential safety hazards.

In diesel fire pumps, overspeed conditions can be caused by fuel control issues, load disconnection, or mechanical failure in the governor system. If the engine RPM rises beyond the safe operational limit (typically 20% above rated speed), the overspeed device activates and stops the engine before severe damage occurs.

The heart of the overspeed protection system is usually an electronic or mechanical overspeed switch, triggered by engine speed sensors. These components must be fast, reliable, and fail-safe because diesel fire pumps are often located in mission-critical facilities such as hospitals, data centers, industrial complexes, and high-rise buildings.

Diesel engines in fire pump systems are governed to maintain a specific RPM, typically around 2950 or 3600 RPM depending on the frequency (50Hz or 60Hz). However, several factors can push the engine past its threshold:

Fuel rack failure or jamming

Governor malfunction

Sudden loss of load

Improper engine maintenance or configuration

When these issues occur, the engine can enter an uncontrollable speed state — risking not only the pump but the entire fire protection infrastructure.

Running a diesel fire pump without overspeed protection is a gamble no facility manager or fire safety engineer should take. Here's why:

Diesel engines are finely tuned machines. If the engine runs significantly above its rated RPM, internal components like pistons, connecting rods, and crankshafts can fail. These are catastrophic failures, often resulting in the total loss of the pump unit.

A fire pump must be available and fully functional during an emergency. If an engine is destroyed due to overspeeding during a fire event, the result can be disastrous. Fire suppression systems may become inoperable, endangering lives and property.

NFPA 20, the standard for the installation of stationary fire pumps for fire protection, mandates the use of overspeed protection devices for diesel engine-driven fire pumps. Operating without it can lead to code violations and insurance issues.

Even if a complete failure doesn’t occur, operating without overspeed protection can lead to excessive wear, misalignment, and long-term degradation of engine components — inflating operational costs significantly.

According to NFPA 20 (2022 Edition), Section 11.2.6, diesel engine fire pumps must be equipped with a dedicated overspeed shutdown mechanism. Key requirements include:

The overspeed shutdown must activate if engine speed exceeds 120% of rated speed.

The mechanism must be independent of the primary engine control system.

A manual reset is required to restart the engine after a shutdown.

Overspeed shutdown should not interfere with fire alarm or monitoring signals.

NFPA emphasizes redundancy and independence to ensure that even if one control system fails, the overspeed protection will still operate effectively.

There are multiple ways to implement overspeed protection in diesel fire pumps. These include:

Simple and effective, these use centrifugal force to mechanically limit RPM. While reliable, they may be slower to respond compared to modern electronic systems.

These systems use digital inputs from speed sensors and offer fast, precise overspeed detection and shutdown. They can also be integrated with system diagnostics and alarms.

Installed near the engine flywheel, magnetic pickups measure rotation speed and relay data to the controller. They are often used with ECMs to ensure accurate detection.

Some fire pump systems use both mechanical and electronic devices in tandem for enhanced safety — a smart approach in high-risk environments.

In one incident at an industrial manufacturing facility, a faulty governor led to a sudden overspeed of the fire pump’s diesel engine during routine testing. Fortunately, the system's electronic overspeed protection device triggered an automatic shutdown within milliseconds — preventing a complete engine blowout. The cost of replacing a $30 overspeed switch was negligible compared to the potential $20,000+ engine replacement — not to mention the facility downtime.

When designing or upgrading your diesel fire pump package, consider the following:

Engine RPM and power rating

Compliance with local and international fire codes (NFPA 20, UL/FM)

Environment (indoor, outdoor, temperature ranges)

Type of control panel (manual, automatic, intelligent)

System integration with fire alarm and monitoring platforms

Working with a qualified fire pump manufacturer ensures proper sizing, installation, and testing of the overspeed protection mechanism.

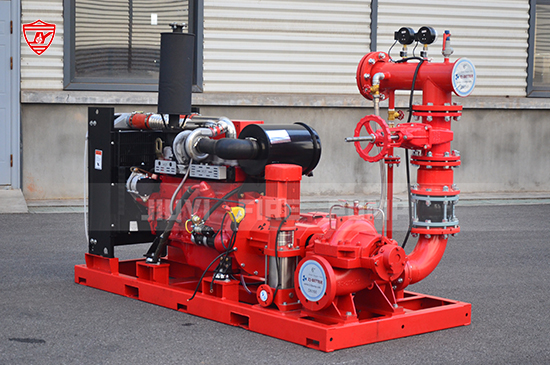

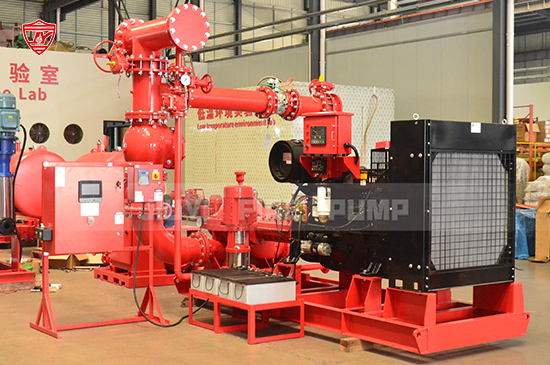

At Better Technology Group, we understand that every component in a fire pump system plays a critical role — especially safety devices like overspeed protection.

All our Diesel Fire Pump Packages are designed to meet or exceed NFPA 20 and UL standards, equipped with certified overspeed shutdown systems, pre-tested in our factory, and ready for mission-critical fire protection applications.

Overspeed protection is not optional — it’s an essential safeguard for the reliability and longevity of diesel engine fire pumps. Whether you are an engineer, contractor, or facility manager, ensuring that your fire pump system includes properly functioning overspeed protection is critical to protecting both life and property.