In any fire protection system, the fire pump plays a critical role in ensuring adequate water pressure is available when it matters most. Whether it's installed in a commercial building, industrial facility, or logistics hub, understanding what triggers a fire pump to run is vital for engineers, facility managers, and fire safety professionals alike.

This article explores the various methods that initiate a fire pump's operation—from automatic pressure-sensing devices to manual activations—ensuring your system responds promptly and reliably during an emergency.

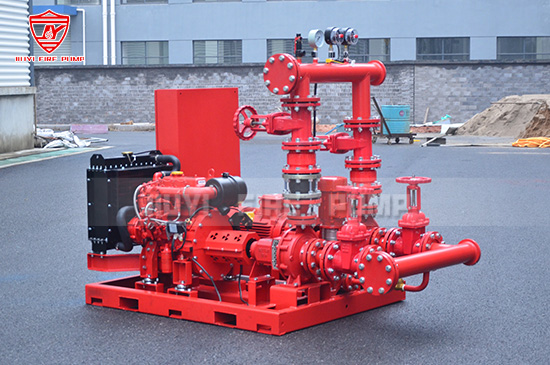

A fire pump is a part of a fire sprinkler or standpipe system that boosts water pressure when the municipal water supply or tank pressure is insufficient. Fire pumps are typically powered by electricity or diesel engines and must be capable of starting immediately during a fire event.

The automatic operation of a fire pump ensures that human intervention is not required when seconds count. The National Fire Protection Association (NFPA 20) mandates that fire pumps must start automatically upon demand for water—usually due to a significant pressure drop caused by sprinkler or hose operation.

The most common and critical trigger for a fire pump to run is a drop in system pressure. Here’s how it works:

Fire pumps are equipped with pressure sensing devices—typically pressure switches or transducers—located on the controller or sensing line. These devices continuously monitor system pressure.

A pressure drop below a predefined threshold (setpoint) signals the controller to start the fire pump. For example, if the normal system pressure is 120 psi and the cut-in pressure is set at 105 psi, a drop below 105 psi will trigger the pump.

This pressure drop can occur due to:

Activation of a sprinkler head due to heat

Opening of a fire hose valve

Sudden system leakage or pipe burst

The moment pressure falls below the cut-in point, the fire pump controller receives a signal and initiates the pump’s start sequence.

Although pressure drop is the most common automatic trigger, other methods also exist to manually or remotely activate the pump when needed:

Most fire pump control panels are equipped with a manual start button or switch. This allows personnel to start the pump directly, typically for testing or in non-pressure-related emergency scenarios.

A remote start station—usually located near fire exits or hose stations—can be installed to allow manual pump initiation from a safe distance. This feature is useful if a fire is detected but has not yet triggered a sprinkler.

In advanced facilities, the fire pump may be integrated with the Building Management System (BMS) or a SCADA (Supervisory Control and Data Acquisition) system. These systems can send start signals based on fire alarm input, flow meter data, or visual smoke detection.

To better understand what triggers a fire pump to run, it's essential to look at the components involved in the start sequence:

The controller is the central command unit that interprets input from sensors and initiates the start process. UL-listed and NFPA 20-compliant controllers are required in most installations.

Mounted on the sensing line, these devices detect changes in system pressure and send signals to the controller.

A jockey pump (or pressure maintenance pump) maintains system pressure under normal conditions and compensates for minor leaks. When pressure falls beyond the jockey pump’s capacity, it signals a possible fire event—prompting the fire pump to start.

Pressure drop or fire pump start may also trigger alarms—both local (audible and visual) and remote—to inform staff or alert the fire department, depending on the system design.

Let’s break down a typical fire pump activation scenario:

A fire starts on the second floor of a commercial building.

Heat activates a sprinkler head, releasing water.

System pressure drops below 105 psi.

The pressure switch detects the drop and sends a signal to the fire pump controller.

The controller initiates the start sequence.

The fire pump starts running—drawing water from the supply and boosting pressure.

The system delivers water to the active sprinkler and any connected hose stations.

For diesel engine-driven fire pumps, the starting mechanism involves additional considerations:

The controller also monitors engine parameters (battery voltage, engine temperature, fuel level).

In the event of a pressure drop, the diesel engine must start within a specified time, usually within 10 seconds.

Diesel engines are often equipped with dual batteries and redundant starting mechanisms to ensure reliability.

Understanding what triggers a fire pump also highlights the importance of regular system testing and maintenance:

Fire pumps should be run at least once a week (per NFPA 25) to ensure readiness.

During these tests, pressure drops can be simulated manually to verify the automatic start.

Pressure sensors should be calibrated to the proper cut-in and cut-out points.

Incorrect calibration can delay or prevent pump activation.

For both electric and diesel pumps, backup power sources must be tested to ensure the pump starts even during a utility outage.

Being aware of potential issues is essential:

Faulty pressure switches

Loose wiring or control panel faults

Disconnected sensing lines

Air locks in the system

Depleted diesel fuel or dead batteries

A comprehensive preventive maintenance program can help prevent these failures.

NFPA 20 sets strict guidelines for the installation and performance of fire pump systems, including automatic startup procedures. Key requirements include:

Automatic start based on pressure drop

Manual and remote start capability

Minimum starting and run-time standards

Controller testing and documentation

Always verify that your fire pump system meets NFPA 20 and local code requirements.

A fire pump must be ready to start the moment it’s needed—no delays, no uncertainty. The most common trigger is a pressure drop caused by system water flow, but manual and remote options provide additional control and flexibility.

As a fire pump manufacturer, we understand how critical it is to engineer and test systems that respond precisely when lives and property are at risk. Ensuring your fire pump starts automatically and reliably requires the right components, proper installation, regular maintenance, and full code compliance.

If you’re unsure whether your fire pump system is properly configured or maintained, reach out to our technical team. We’re here to support you with expert advice and high-performance fire pump solutions.