Fire pumps are the heart of a fire protection system. When a fire breaks out, the reliability of these pumps determines whether water will be delivered at the right pressure and flow to suppress the flames. But a fire pump cannot be trusted unless it is regularly tested and maintained. That brings us to a critical question for facility managers, fire safety professionals, and building owners: What is the best fire pump test frequency?

This article explores NFPA requirements, practical best practices, and expert insights into fire pump testing schedules. By the end, you’ll understand exactly how often your fire pump should be tested to keep your building compliant and safe.

A fire pump sits idle for most of its life. Unlike other equipment that operates daily, a fire pump may only run when a fire occurs—or during testing. Because of this, even minor issues can remain hidden until it’s too late. Regular testing ensures that:

The fire pump starts automatically when needed.

Valves, controllers, and power supplies function correctly.

Water flow and pressure meet design requirements.

Any mechanical or electrical issues are identified before an emergency.

Without consistent testing, you risk system failure during a fire, potential non-compliance with fire codes, and liability issues.

The National Fire Protection Association (NFPA) outlines testing requirements in NFPA 25: Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems. According to NFPA 25, the required fire pump test frequency depends on the pump type:

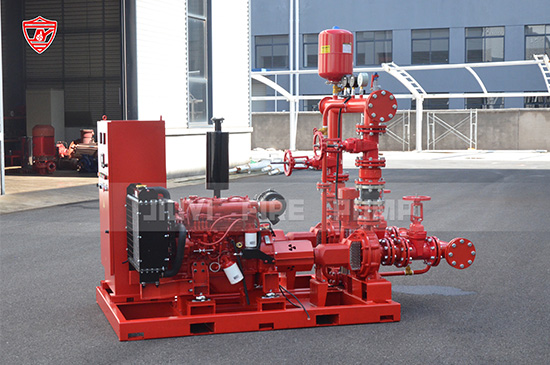

Diesel Engine Fire Pumps: Must be run weekly under no-flow (churn) conditions for at least 30 minutes.

Electric Motor Fire Pumps: Must be run weekly for 10 minutes (some jurisdictions may allow monthly testing if the pump is connected to a reliable power source).

Purpose: Verifies that the fire pump starts automatically, controllers function, and all components operate without issues.

All fire pumps, regardless of power type, must undergo a full flow test annually.

This involves measuring pump performance at no-flow, rated flow, and 150% of rated flow conditions.

Purpose: Ensures the pump can still meet its original design specifications.

Monthly: Inspect pump rooms, water levels in suction tanks, and check valve positions.

Quarterly: Inspect pump operation, alarms, and controllers.

Every 5 years: Conduct performance testing of suction piping and internal inspections.

While NFPA 25 sets the minimum requirements, many facilities adopt more frequent or detailed testing based on their risk level, occupancy type, and insurance requirements. Best practices include:

Weekly (all pumps): Even if NFPA allows monthly testing for electric pumps, many safety managers still run weekly tests to be safe.

Monthly Performance Checks: Record data such as suction/discharge pressure, flow meter readings, and power supply performance.

Condition-Based Maintenance: Use vibration analysis, thermal imaging, and oil analysis on diesel engines to predict failures.

Post-Repair Tests: Always test pumps after maintenance, repairs, or electrical work.

Skipping Weekly Tests: Many facilities rely only on annual testing, which leaves pumps vulnerable to unnoticed failures.

Improper Recording: Test data must be logged and compared to baseline values. Incomplete logs make trend analysis impossible.

Neglecting Controllers: A pump is useless if its controller fails to start it during a fire. Controllers need inspection and testing as much as the pump itself.

Ignoring Diesel Engine Maintenance: Fuel supply, batteries, and cooling systems must be checked regularly for diesel-driven pumps.

Flow Test Shortcuts: A proper annual flow test should measure performance at multiple points, not just a quick pressure check.

Here’s a practical schedule for fire pump testing and inspection that combines NFPA standards with best practices:

Run diesel engine pumps for 30 minutes.

Run electric motor pumps for 10 minutes.

Verify automatic starting from pressure drop.

Check gauges, valves, and packing glands.

Record suction and discharge pressures.

Inspect controller status indicators.

Verify water levels in suction supply tanks.

Inspect pump room for leaks, corrosion, or obstructions.

Check diesel fuel, coolant, and battery condition.

Inspect alarm and signal transmission.

Verify power supply connections.

Test relief valves and pressure sensing lines.

Conduct full flow test (churn, 100%, and 150% capacity).

Calibrate pressure gauges.

Inspect impellers, bearings, and shafts.

Perform vibration and temperature analysis.

Internal inspection of pump casing and piping.

Ultrasonic or hydrostatic testing of piping systems.

By sticking to an appropriate test frequency, facilities gain multiple benefits:

Code Compliance: Meeting NFPA 25 and local fire codes avoids penalties.

Reliability in Emergencies: Pumps are more likely to perform when needed.

Reduced Downtime: Early detection of issues prevents costly failures.

Insurance Benefits: Many insurers require proof of regular pump testing.

Extended Equipment Life: Consistent operation prevents mechanical issues from long idle periods.

While NFPA sets a baseline, the best frequency also depends on:

Building Type: Hospitals, data centers, and high-rise buildings may require stricter schedules.

Pump Age: Older pumps may need more frequent testing.

Local Authority Requirements: AHJs (Authorities Having Jurisdiction) may enforce stricter standards.

Insurance Carrier Demands: Some insurers require weekly electric pump testing regardless of NFPA’s monthly allowance.

Environmental Conditions: Corrosive environments or unstable power supplies may call for more frequent checks.

Most fire safety professionals recommend following NFPA standards at a minimum, but also tailoring the schedule to your facility. A good rule of thumb is:

Diesel pumps: Always test weekly.

Electric pumps: Test weekly unless AHJ allows monthly, but weekly is safer.

Annual full flow test: Never skip, as it provides the most comprehensive performance check.

So, what is the best fire pump test frequency?

According to NFPA 25, diesel fire pumps must be tested weekly, electric fire pumps at least monthly (though weekly is better), and all pumps must undergo an annual full flow test. Beyond that, proactive facilities layer in monthly, quarterly, and five-year inspections to ensure reliability.

In short, the best frequency is one that not only complies with NFPA requirements but also reflects your building’s risk profile and operational needs. The investment in regular testing is far less than the cost of fire pump failure during an emergency.