Selecting a UL fire pump set for an industrial plant is one of the most critical decisions in designing a reliable fire protection system. Industrial facilities—such as chemical plants, manufacturing sites, oil and gas terminals, logistics warehouses, steel factories, and power stations—carry higher fire risks and require pumps that can deliver certified performance under emergency conditions.

In this article, we provide a complete, detailed guide on how to choose the right UL listed fire pump set for industrial projects, covering design requirements, pump sizing, driver selection, system components, installation considerations, and long-term maintenance.

As a manufacturer of UL fire pumps, we aim to help engineers, consultants, and project managers make informed decisions to ensure both compliance and safety.

Under NFPA 20, fire pumps must deliver dependable water flow and pressure during fire events. However, in high-risk industrial environments, performance must be guaranteed, not just projected.

A UL listed fire pump ensures:

Verified performance through independent testing

Compliance with globally recognized NFPA 20 standards

Reliable operation under real fire conditions

Reduced risk of system failure

Increased approval likelihood by insurers, consultants, and AHJs

For factories or industrial plants, insurance companies often require UL/FM certified pumps. Using non-certified pumps may reduce initial cost but increases long-term risk and potentially voids insurance coverage in the event of fire.

Before selecting any UL fire pump set, engineers must first determine the fire protection water demand. This is typically based on:

Building type and fire hazard classification

Sprinkler system design (CMDA, ESFR, CMSA, deluge, etc.)

Local fire code requirements

Required duration of water supply

Presence of fire hydrants, monitors, or foam systems

Key parameters that must be known:

Required flow (GPM or L/min)

Required pressure (PSI or bar)

Net pressure available from the water source

Pump room layout and available space

Industrial plants often demand higher capacities, commonly:

500–3000 GPM for sprinkler systems

2000–5000 GPM for combined hydrant and sprinkler systems

2500–6000 GPM for petroleum or chemical sites

Once demand is known, engineers can begin selecting the appropriate UL fire pump model and driver.

NFPA 20 allows multiple pump types to be UL listed. The most common options for industrial facilities include:

Suitable for moderate flows up to around 750–1000 GPM.

Ideal for compact pump rooms or small industrial facilities.

Most popular for industrial projects due to high reliability.

Advantages include:

High efficiency

Longer service life

Easy maintenance

Flow capacities from 500–5000+ GPM

This is the most recommended type for large plants.

Best for sites with water drawn from:

Groundwater wells

Lakes

Rivers

Open reservoirs

Vertical turbine pumps are mandatory when the water source is below pump suction level.

Used in high-pressure applications or tall structures.

Suitable for industrial plants with multi-level fire systems.

When selecting pump types, consider water source, required performance, and maintenance accessibility.

Correct pump sizing is crucial for ensuring fire protection systems operate effectively.

NFPA 20 requires pumps to supply the system demand at minimum flow, but with safety margin. For industrial systems:

Choose pump flow equal to or slightly above system demand

Avoid oversizing (causes churn heating and energy waste)

Typical industrial flows range from 1000–3000 GPM. Select the closest UL certified flow rating.

Pump pressure must overcome:

System pressure demand

Elevation difference

Friction losses in piping

Hose stream demand for hydrant systems

Common industrial pressures are 100–200 PSI. Determine the target discharge pressure based on worst-case scenario.

Review the UL-approved pump curve carefully to confirm:

Rated pressure at 100% flow

115% pressure requirement at 100% flow (UL rule)

65% pressure at 150% flow

Driver selection depends on site conditions, power reliability, and regulatory requirements.

Advantages:

Lower maintenance

Stable performance

Lower noise

Cost-effective for continuous power sites

Recommended when electrical power supply is stable and meets NFPA 20 requirements.

Advantages:

Independence from electrical grid

Ideal for remote or unstable power environments

Mandatory in some high-risk facilities

Industrial plants with unreliable power or high outage risk—such as manufacturing parks, chemical plants, and offshore facilities—commonly choose diesel-driven UL pumps.

NFPA 20 also requires specific components for diesel UL sets, including:

Two storage batteries

Fuel tank sized for minimum 8 hours

Battery charger

Engine cooling system

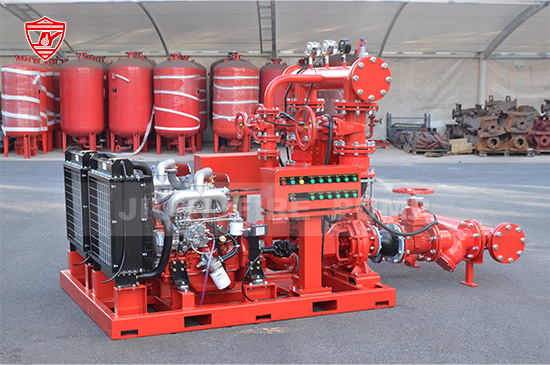

A complete UL fire pump set includes more than just the pump and driver. Engineers must ensure the entire system complies with NFPA 20.

Essential components:

UL listed pump

UL listed electric motor or diesel engine

UL listed controller

Jockey pump and controller

Base frame and coupling

Automatic valves and fittings

Pressure gauges

Relief valve (when required)

Suction and discharge piping arrangement

Flow test device (test header or flowmeter)

For industrial plants, a packaged fire pump system is often preferred because:

It reduces installation time

Ensures proper alignment and compliance

Simplifies inspection and testing

Improves overall reliability

Controllers are critical because they start and operate the pump during emergencies. For UL fire pump sets, the controller must also be UL listed.

Two main types:

Electric motor controllers

Diesel engine controllers

Key features to evaluate:

Automatic and manual start

Sequential start for multiple pumps

Emergency shutdown

Pressure switches

Remote monitoring capability

In industrial plants requiring high uptime, consider controllers with enhanced diagnostics and event reporting.

Proper installation ensures the pump delivers certified performance.

Key factors:

Pump room must be accessible and protected

Maintain required clearances for maintenance

Provide adequate ventilation (especially for diesel pumps)

Ensure correct suction piping layout (straight run, no high points)

Install vibration isolation to protect piping

Follow NFPA 20 requirements for valves, gauges, and fittings

UL fire pump sets must be installed exactly as per certification guidelines to avoid invalidating compliance.

Before handing over the system, the UL fire pump must be tested.

Essential procedures include:

No-flow (churn) test

100% rated flow test

150% rated flow test

Alarm and controller test

Diesel engine start and transfer test

Record the pump curve to confirm it matches UL performance. Any major deviation requires corrective action.

Industrial fire pump systems must be maintained to ensure readiness. Recommended practices include:

Weekly:

Diesel engine test

Controller inspection

Visual checks

Monthly:

Jockey pump operation

Battery maintenance

Pressure switch checks

Annual:

Full flow test

Controller function test

Valve inspection

Pump room safety inspection

Factories with high-risk operations may conduct more frequent checks.

Selecting the right manufacturer is as important as selecting the pump.

A reliable UL fire pump supplier should offer:

Full UL certified pump ranges

Diesel and electric options

Packaged fire pump systems

Strong engineering support

Proper documentation for contractors and consultants

Technical assistance for installation and commissioning

Industrial plants benefit from suppliers who can provide long-term service, spare parts, and technical guidance—not just a pump.

Choosing the right UL fire pump set is essential for protecting industrial facilities that face high fire risks. Engineers must evaluate water demand, pump type, performance requirements, driver selection, UL certification, NFPA 20 compliance, installation conditions, and long-term maintenance needs.

A carefully selected UL listed fire pump system not only ensures operational reliability but also helps industrial plants meet insurance requirements, minimize downtime, and enhance overall fire safety.