ire pumps are the backbone of any building’s fire protection system, designed to deliver adequate water pressure during emergencies. Even the most advanced fire pump systems can fail if not tested and maintained regularly. This is why weekly testing, as outlined in NFPA 25 (Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems), is so critical.

In this article, we’ll walk through how to conduct a fire pump weekly test correctly, discuss why it matters, and provide practical guidance for ensuring your fire pump operates reliably when needed most.

Unlike other mechanical systems that operate daily, fire pumps remain idle until an emergency arises. This inactivity can allow issues—such as stuck valves, leaks, or engine malfunctions—to go unnoticed. Weekly tests serve several purposes:

Ensures readiness: Confirms that the fire pump will start and run as designed.

Detects early problems: Identifies small issues before they turn into system failures.

Maintains compliance: NFPA 25 requires weekly fire pump tests for most systems.

Protects lives and assets: An operational fire pump is vital for delivering water during a fire emergency.

Without consistent testing, facilities risk pump failure at the most critical moment.

NFPA 25 specifies different requirements depending on pump type:

Diesel Engine Fire Pumps: Must be tested weekly.

Electric Motor-Driven Fire Pumps: May be tested monthly, unless required more frequently by local code or insurance authority.

Vertical Turbine Fire Pumps: Require special considerations due to their design.

For the purpose of this article, we’ll focus on the general procedure for weekly testing, applicable across most installations.

Before starting, safety and preparation are essential:

Review system records: Ensure you have the latest maintenance log.

Notify stakeholders: Inform building occupants and monitoring stations to avoid false alarms.

Check water supply: Confirm suction tank levels or municipal supply availability.

Inspect the area: Look for leaks, obstructions, or unusual conditions around the pump.

Follow manufacturer guidelines: Some pumps may have unique instructions in addition to NFPA requirements.

A proper weekly fire pump test includes both no-flow (churn) testing and observation of critical parameters. Here’s a step-by-step process:

For electric pumps, use the manual start switch on the controller.

For diesel pumps, follow the manufacturer’s cranking procedure.

The pump should start smoothly. Record the time it takes for the pump to reach full operation.

Check the control panel for:

Proper indication lights

Absence of alarm conditions

Correct automatic start readiness

Note suction pressure (incoming water) and discharge pressure (outgoing water). Compare with baseline readings from acceptance tests.

During the 10-minute run (NFPA 25 minimum for diesel, shorter for electric), check for:

Smooth operation without vibrations or unusual noise

Stable discharge pressure

Consistent water flow into the test header (if applicable)

Simulate a pressure drop to confirm the pump starts automatically. This ensures the system will respond without human intervention.

For diesel-driven fire pumps, record:

Fuel level

Oil pressure

Battery voltage

Engine temperature

Exhaust system condition

After the run, return the pump to automatic mode. Reset any alarms and ensure the system is ready for emergency use.

Complete a test log, including:

Date and time

Pump type and identification

Readings for suction/discharge pressures

Duration of test

Observed issues or maintenance actions taken

Weekly fire pump testing often reveals problems that might otherwise remain hidden. Typical issues include:

Failure to start automatically – Often linked to electrical or controller faults.

Pressure fluctuations – May indicate air leaks, clogged strainers, or valve issues.

Unusual noise or vibration – Possible pump alignment or bearing problems.

Diesel engine concerns – Low fuel, oil leaks, or battery failures.

Leaking seals or gaskets – Small leaks can worsen quickly if not addressed.

Detecting and resolving these early prevents costly repairs and potential system failure.

To maximize the effectiveness of your testing program, follow these best practices:

Maintain consistency: Conduct tests on the same day and time each week.

Train staff properly: Ensure personnel are familiar with NFPA 25 requirements and pump manufacturer guidelines.

Use a checklist: A standardized form prevents oversight of critical steps.

Trend data: Keep long-term logs to spot performance degradation over time.

Engage professionals: Supplement weekly inspections with annual flow testing by qualified contractors.

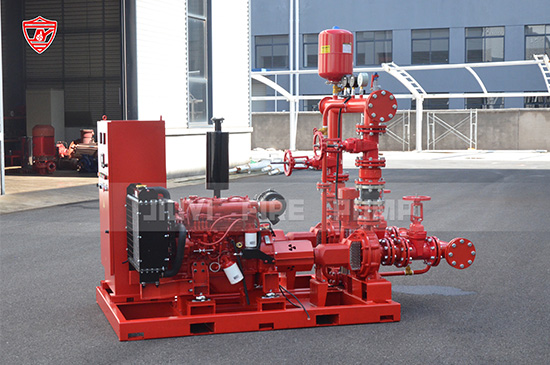

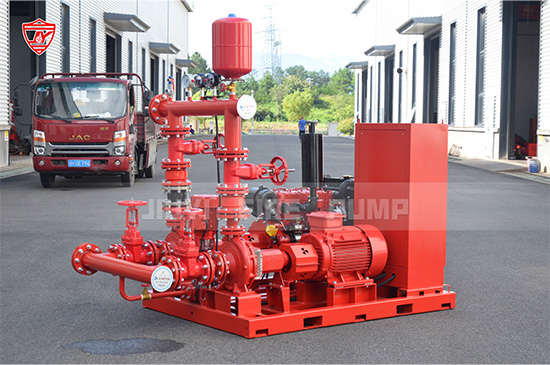

As a manufacturer of fire pumps, we design systems with testing and maintenance in mind. Our pumps are built to meet NFPA 20 and UL/FM standards, ensuring durability and compliance. However, even the most reliable equipment needs routine testing.

By following the correct weekly test procedure, building owners, facility managers, and safety officers can ensure that their investment in fire protection equipment delivers the intended level of safety.

A fire pump may only be called upon once in its lifetime—but in that moment, its performance determines the difference between a contained fire and a devastating loss. Conducting weekly fire pump tests is not just a regulatory requirement; it is a best practice that safeguards lives, property, and business continuity.

By adhering to NFPA 25 guidelines, documenting results, and addressing issues promptly, facility teams can ensure that their fire pump will perform reliably when needed most. Regular testing is the simplest, most cost-effective step toward guaranteeing fire safety readiness.