Fire pumps are vital components in fire protection systems, ensuring water is available for firefighting in the event of an emergency. Regular checks and maintenance of your fire pump can mean the difference between an effective response and failure when you need it most. So, how can you verify that your fire pump is functioning correctly? Here’s a step-by-step guide to help you conduct an effective fire pump inspection.

Before diving into the checks, it’s essential to understand the importance of maintaining your fire pump. A fire pump that’s not working correctly can result in inadequate water supply during a fire emergency. Properly functioning pumps are critical for the overall efficiency of your fire suppression system. Regular checks ensure:

Adequate Water Pressure: The pump ensures a consistent, high pressure for effective firefighting.

Reliability During Emergencies: The pump must work seamlessly when needed in an emergency.

Compliance with Fire Safety Standards: Regular checks ensure that the pump meets industry standards, such as NFPA 20 or UL certification.

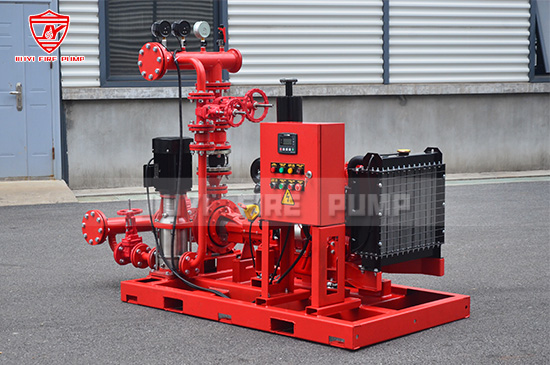

A simple yet effective first step is conducting a visual inspection of the pump and its components. The objective is to check for obvious signs of damage or wear and tear that may affect functionality.

Pump Housing: Ensure the pump casing is intact with no visible cracks or signs of corrosion.

Piping and Valves: Check that all pipes and valves are secure, with no leaks or damage.

Drive Mechanism: For diesel-powered pumps, inspect the engine, while for electric pumps, check the motor.

Alarm and Control Panel: Ensure the alarm system is functional and check the control panel for any warning lights or malfunctions.

If any of these components show signs of damage or deterioration, repairs or replacements may be necessary.

One of the most crucial tests for your fire pump is to check the pressure it generates. The fire pump is designed to deliver water at a specific pressure based on system requirements, and insufficient pressure can render the system ineffective during an emergency.

Install a Pressure Gauge: Attach a pressure gauge to the discharge valve or test valve.

Start the Pump: Turn on the pump and allow it to operate at full capacity.

Monitor the Pressure: Observe the pressure reading on the gauge. It should match the specifications outlined in the manufacturer’s manual. If the pressure is too low or too high, this could indicate a malfunctioning pump or other issues like clogged pipes or a faulty valve.

Note: The pressure test should be conducted periodically as part of your routine maintenance schedule to ensure the pump is performing optimally.

In addition to pressure, you’ll need to check the flow rate of the fire pump. The flow test ensures that the pump is delivering the required volume of water to meet firefighting needs.

Set Up the Test Hose: Attach a flow meter to a hose or discharge nozzle.

Start the Pump: Turn on the fire pump and allow it to operate at maximum capacity.

Measure the Flow: The flow meter will give you a reading of the water volume being discharged per minute. Compare this reading with the required flow rate outlined in the system specifications.

If the flow rate is lower than the required value, the pump may need maintenance or repairs to restore optimal performance.

For diesel engine fire pumps, engine performance is critical. You need to ensure that the engine starts promptly and runs smoothly under load. Similarly, for electric pumps, you need to check the motor's functionality.

Fuel System: Check fuel levels and ensure the fuel system is free from leaks or contamination.

Coolant System: Inspect the radiator and coolant system to ensure there are no leaks and the system is properly filled.

Battery: Test the battery to ensure it’s fully charged and capable of starting the engine.

Exhaust: Check for any unusual exhaust emissions or sounds, as these could indicate engine problems.

Power Supply: Ensure the motor is receiving a stable power supply. Check the connections for signs of wear or corrosion.

Motor Overload: Ensure the motor isn’t experiencing overheating. Overloaded motors can cause system failures.

Jockey pumps are smaller pumps that maintain pressure in the system when the fire pump is not running. These pumps prevent the larger fire pump from starting unnecessarily during small pressure fluctuations.

To check if the jockey pump is working:

Check the Pressure Switch: Ensure that the pressure switch activates the jockey pump at the correct pressure setting.

Test the Pump: The jockey pump should turn on automatically when pressure drops below the set threshold, and it should stop when the pressure reaches the ideal level.

The fire pump control system is responsible for starting and stopping the pump as needed, monitoring performance, and activating alarms when something goes wrong. It is essential to inspect this system regularly to ensure it’s working as intended.

Control Panel: Inspect the panel for any errors, warning lights, or malfunction indicators. Check the status of the alarm system.

Automatic Start Feature: Test the automatic start feature by simulating an emergency or pressure drop scenario to ensure the pump starts as expected.

Manual Override: Ensure the manual override feature works in case automatic startup fails.

Fire pumps, particularly diesel engine models, can produce vibrations and sounds during operation. However, unusual vibrations or loud noises may indicate an issue such as imbalance, bearing failure, or cavitation.

Listen Carefully: While the pump is running, listen for any irregular noises such as grinding, whining, or knocking.

Check for Excess Vibration: Excessive vibration can be a sign of a misaligned or damaged component.

After performing these checks, it’s essential to document the results for future reference. Keep a record of any irregularities or concerns so that repairs can be scheduled, and you can monitor the performance over time.

A properly functioning fire pump is crucial to any fire protection system. Regular checks and maintenance ensure that your system is always ready to respond in an emergency. By following this guide and performing periodic inspections, you can ensure the reliability and efficiency of your fire pump.

If you notice any issues during your inspection or if you’re unsure about how to perform the tests, it’s best to contact a professional fire pump technician. Routine maintenance and prompt repairs will help extend the lifespan of your pump, keeping you compliant with safety standards and ensuring safety when it matters most.